List of Codes and Standards Applicable to Hydrogen Fuel Cell

advertisement

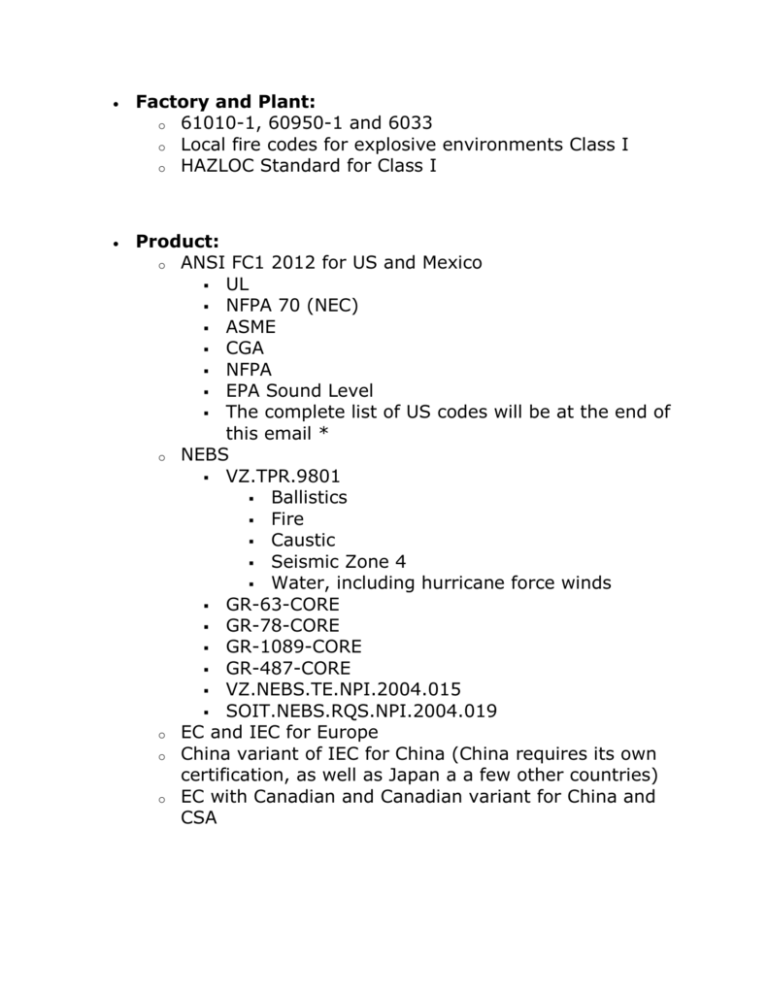

Factory and Plant: o 61010-1, 60950-1 and 6033 o Local fire codes for explosive environments Class I o HAZLOC Standard for Class I Product: o ANSI FC1 2012 for US and Mexico UL NFPA 70 (NEC) ASME CGA NFPA EPA Sound Level The complete list of US codes will be at the end of this email * o NEBS VZ.TPR.9801 Ballistics Fire Caustic Seismic Zone 4 Water, including hurricane force winds GR-63-CORE GR-78-CORE GR-1089-CORE GR-487-CORE VZ.NEBS.TE.NPI.2004.015 SOIT.NEBS.RQS.NPI.2004.019 o EC and IEC for Europe o China variant of IEC for China (China requires its own certification, as well as Japan a a few other countries) o EC with Canadian and Canadian variant for China and CSA * The following is a complete list of codes for USA and countries that follow ANSI standard: ANSI FC 1 2012 Stationary Fuel Cell Systems NFPA 2 Hydrogen Technologies Code NPA 50 Handling of oxygen (for DOX system only) NFPA 50A Handling of hydrogen NFP 55 Compressed Gas and Cryogenics Code NFPA 70A & B Electrical Safety NFPA 853 Standard for Installing Stationary Fuel Cell IBC Fuel Cells for Backup Power in Telecommunications Facilities IMC Permitting Fuel Cell Installations NEC, Article 692 Electrical Safety for Fuel Cell ICC K1202 Stationary Fuel Cell Power Systems UL 1741 (Ed.1) Inverters, Converters, Controllers and Interconnection System Equipment for Use With Distributed Energy Resources International Building Code o Canopy top storage of hydrogen to be classified as outdoor storage International Fire Code o Allows fuel for fuel-cell power system to be located on utility easement o Adds reference to UL 2075-2007 for gas detectors in areas repairing hydrogen vehicles o Clarifies that NFPA 55 applies to Bulk GH2 and LH2 systems o Clarification of weather protection for stationary fuel cells using hydrogen International Fuel Gas Code o Stationary fuel cell to be installed in accordance with manufacturer’s instructions, NFPA 853 and the IBC & IFC. NREL Codes and Standards for Stationary Fuel Cells NREL/TP-560-47336 o Siting: must be placed on a firm foundation above base flood elevation vent and exhaust terminations separate from doors, windows, outdoor air intakes, and other building openings accessible to service 5 ft away from combustible materials, hazardous chemicals, and other fire exposures fire or failure to not present hazard to adjacent fuel cell systems o Fire Prevention and Emergency Planning written information on fire prevention procedures, plant emergency alarms, and egress procedures requirements to conduct and document inspections written description of housekeeping practices and the control of transient combustibles written procedures for handling flammable and combustible gases and liquids written procedures for handling ignition sources written procedures to address system impairments written procedures for conducting a fire investigation list of periodic inspections, testing, etc warning signage location of operating instruction CGA FC 1 Stationary Fuel Cell Power Systems CGA P1 Safe Handling of Compressed Gasses in Containers CGA G-5.5 Hydrogen Venting Systems CGA H2 Classification and Labeling of Hydrogen ASME B31.3 ASME BPVC OSHA Note 1: In addition to standard OSHA Codes, there are special requirements for Explosive Environment Class I which can be found in NFPA 1 Code and Note 2: There may be special local fire codes for hazardous and explosive environment, as well as for storage, handling, and use of hydrogen, oxygen, and caustic substances (potassium hydroxide). Note 3: There will be both EPA and local codes for the safe handling and proper disposal of the dangerous waste material and waste water (potassium hydroxide and acids) Note 4: Must have adequate supplies of citric acid for spills and splash. Must have specific eyewash for both acids and caustic base. Must have proper chemical protective suits, goggles, aprons, gloves and breathing protection from both caustic dust and vapor. Note 5: Must have both OSHA and NFPA training for explosive environment, safe handling of both hydrogen and oxygen, and fire handling in case of either oxygen or hydrogen explosion. Note 6: Venting is mandatory of the different gasses, and they must be separated by distance, i.e., one venting system of oxygen, one for hydrogen, and one for handling the potassium hydroxide dust which must be filtered. The combining of any of these gases with each other, or with the dust from potassium hydroxide could be catastrophic. Note 7: Hydrogen leak detection system must be installed per NFPA alarm and signaling codes. Note 8: Any storage of hydrogen and oxygen must be stored outside at least 20 feet apart, both with local and remote emergency shutoff buttons. Note 9: All electrical products and motors must be rated to work in explosive environment. Note 10: All tools should be spark resistant for explosive environments, and adequate protection for retardation of static spark should be implemented throughout the workplace, and/or static proof shoes or use of mats.