3110-StudyGuide

advertisement

Exam 1 Study Guide

PROBLEMS

1.

Mabel's Ceramics spent $3000 on a new kiln last year, in the belief that it would cut energy usage 25%

over the old kiln. This kiln is an oven that turns "greenware" into finished pottery. Mabel is concerned

that the new kiln requires extra labor hours for its operation. Mabel wants to check the energy savings of

the new oven, and also to look over other measures of their productivity to see if the change really was

beneficial. Mabel has the following data to work with:

Production (finished units)

Labor (hrs)

Capital ($)

Energy (kWh)

The year before

4000

350

15000

3000

Year just ended

4100

375

18000

2600

Also, suppose that the average labor cost is $12 per hour, cost of capital is 20%, and cost of energy is

$0.40 per kwh.

a. Were the modifications beneficial? (Compute labor, energy, and capital productivity for the two

years and compare.)

b. Compute percentage change in multi-factor productivity of the year just ended from that of year

before.

c. If the multifactor productivity for next year must be restored to what it was the year before, assuming

the same output next year as the year just ended, by how the input must be reduced from what it is

this year?

2.

An Appliance Service company made house calls and repaired 10 lawn-mowers, 2 refrigerators, and 3

washers in an 8-hour day with his standard crew of 3 workers. The retail price for each respective service

is $50, $200, and $120. The average wage for the workers is $12 per hour. The materials cost for a day

was $200 while the overhead cost was $50.

a. What is the company’s labor productivity?

b. What is the multifactor productivity?

c. How much of a reduction in input is necessary for a 5% increase in multifactor productivity?

3.

Consider the tasks, durations, and predecessor relationships in the following network. Draw the AON

network and answer the questions that follow.

Activity Description

A

B

C

D

E

F

G

H

I

J

Immediate

Predecessor(s)

--A

A

B

D, C

C

F

F

E, G

I

Optimistic

(Weeks)

4

2

8

1

6

2

2

6

4

1

Most Likely

(Weeks)

7

8

12

2

8

3

2

8

8

2

Pessimistic

(Weeks)

10

20

16

3

22

4

2

10

12

3

a.

b.

c.

d.

4.

Schedule the activities of this project and determine (i) the expected project completion time, (ii)

the earliest and latest start and finish times, and the slack for all the activities, and (iii) all the

critical paths.

What is the probability of completion of the project before week 42?

What is the probability of completion of the project before week 35?

With 99% confidence what is your estimate for the project completion time.

Consider the following project. All activity times are in weeks.

Activity

A

B

C

D

E

F

G

H

I

a.

b.

c.

d.

e.

Immediate

Predecessor(s)

A

A, B

B

C

D, E

E

F, G

Normal

Time

7

8

9

8

9

10

5

10

5

Crash

time

4

5

7

8

8

8

5

8

4

Normal

cost

20000

50000

80000

30000

10000

90000

25000

32000

28000

Crash

cost

38000

74000

110000

30000

12000

124000

25000

40000

35000

Draw an AON network.

Identify all the unique paths from start to finish and determine the critical path, normal

project completion time, and normal project cost.

Compute MAC, Cost of crashing/week.

Which activity would you crash first and by how many weeks?

Determine the project time and cost after crashing the activity selected in (d).

5.

Consider the following CPM Solver model.

a) Determine the successor activities in cells I2 to I10.

b) Determine the Excel formulas for the following cells: F2, G2, C15, C18, D18, D21, C25, G19, G16,

G15, H15, B27, B28, and B29.

c) What is the Solver Target cell for minimizing the project completion time?

d) What is the Solver changing cell range?

e) What are the Solver constraints?

6.

What is the forecast for May based on a 3-period MA and a weighted 3-period moving average

applied to the following past demand data? Let the weights be, 3, 3, and 4 (last weight is for

most recent data). Compute MAD, MSE and MAPE for both cases and compare.

Nov.

37

7.

Dec.

36

Jan.

40

Feb.

42

Mar.

47

April

43

Sales of music stands at the local music store over the past ten days are shown in the table below.

Forecast demand using exponential smoothing with an of .6 (initial forecast = 16).

a) Compute the forecast for period 6 and the MAD.

b) Compute the tracking signal for periods 1 to 5. What do you recommend for this forecasting process?

t

Demand

1

13

2

21

3

28

4

37

5

25

8.

Weekly sales of copy paper at Cubicle Suppliers are in the table below. Forecast week 8 with a trend

projection model.

Week

Sales (cases)

1

17

2

22

3

27

4

32

5

35

6

37

7

41

9.

The quarterly sales for specific educational software over the past three years are given in the following

table. Compute the four seasonal indices and find forecast for Year 4 if the annual demand for year 4 is

estimated to be 10% more than that of year 3.

Quarter 1

Quarter 2

Quarter 3

Quarter 4

10.

YEAR 1

1690

940

2625

2500

YEAR 2

1800

900

2900

2360

YEAR 3

1850

1100

2930

2615

Arnold Tofu owns and operates a chain of 12 vegetable protein "hamburger" restaurants in northern

Louisiana. Sales figures and profits for the stores are in the table below. Sales are given in millions of

dollars; profits are in hundred thousand dollars.

Store

1

2

3

4

5

6

7

8

9

10

11

12

a.

b.

Sales

7

2

6

4

14

15

16

12

14

20

15

7

Profits

15

10

13

15

25

27

24

20

27

44

34

17

Calculate a regression line for the data. What is your forecast of profit for a store with sales of

$24 million? $30 million?

Calculate the standard error of the estimate.

c.

11.

Determine the value of the coefficient of correlation between sales and profit and the value of

the coefficient of determination.

A restaurant manager tracks complaints from the diner satisfaction cards that are turned in at each table.

The data collected from the past week’s diners appear in the following table.

Complaint

Food taste

Food temperature

Order mistake

Slow service

Table/utensils dirty

Too expensive

Frequency

80

9

2

16

47

4

Prepare a Pareto chart. To cover 80% of problems which complaints must be address first?

12.

A list of issues that led to incorrect formulations in Tuncey Bayrak’s jam manufacturing unit in

New England is provided below:

Incorrect measurement

Variability in scale accuracy

Antiquated scales

Equipment in disrepair

Lack of clear instructions

Technician calculation off

Damaged raw material

Jars mislabeled

Operator misreads display

Temperature controls off

Inadequate cleanup

Incorrect weights

Incorrect maintenance

Priority miscommunication

Inadequate flow controls

Inadequate instructions

Create a fish-bone diagram and categorize these issues using the “four Ms” method.

13.

Cartons of Plaster of Paris are supposed to weigh exactly 32 oz. Inspectors want to develop process

control charts. They take ten samples of six boxes and weigh them. Based on the following data, compute

the lower and upper control limits and determine whether the process is in control.

Sample

1

2

3

4

5

14.

Mean

33.8

34.4

34.5

34.1

34.2

Range

1

0.3

0.5

0.7

0.2

Sample

6

7

8

9

10

Mean

34.3

33.9

34.0

33.8

34.0

Range

0.4

0.5

0.8

0.3

0.3

McDaniel Shipyards wants to develop control charts to assess the quality of its steel plate. They take ten

sheets of 1" steel plate and compute the number of cosmetic flaws on each roll. Each sheet is 20' by 100'.

Based on the following data, develop limits for the control chart and determine whether the process is in

control.

Sheet

Number of flaws

Sheet

Number of flaws

1

6

6

2

2

1

7

1

3

4

5

3

2

1

8

9

10

0

0

2

15.

Rancho No Tengo Orchards wants to establish control limits for its mangos before they are sent to the

retailers. They randomly take six containers (assume it is enough) of one hundred mangos in an attribute

testing plan and find some mangos with blemishes. What should be the limits on the control chart? Is the

process in control?

Container

Number of mangos with blemishes

1

5

2

3

3

1

4

3

5

4

6

2

16.

A woodworker is concerned about the quality of the finished appearance of her work. In sampling units

of a split-willow hand-woven basket, she has found the following number of finish defects in ten units

sampled: 4, 0, 3, 0, 1, 0, 1, 1, 0, 2.

a. Calculate the average number of defects per basket

b. If 3-sigma control limits are used, calculate the lower control limit, centerline, and upper control

limit.

17.

The specifications for a plastic liner for concrete highway projects call for a thickness of 6.0 mm ± 0.1

mm. The standard deviation of the process is estimated to be 0.02 mm. What are the upper and lower

specification limits for this product? The process is known to operate at a mean thickness of 6.04 mm.

Determine the values of Cpk and Cp for this process. Is the process capable? Explain.

18.

A medical supplies company buys its supplies in bulk and redistributes them to doctor’s offices and

clinics. The receive thermometers in lots of 500 from the vendor. They are considering a sampling plan

of n = 50 and c = 1.

a. Develop a OC curve for this sampling plan. (Use Poisson Tables)

b. Determine the producer’s risk if the AQL is 2%.

c. Determine the consumer’s risk if the LTPD is 14%.

d. Develop a curve for AOQ and determine the value of AOQL.

19.

An acceptance sampling plan has lots of 5000 units, a sample size of 200 and c is 5. Suppose that the

incoming lots have percentage defective of 3%. What is AOQ?

Answers:

1.

The energy modifications did not generate the expected savings; labor and capital productivity

decreased.

Given data

Production

Labor

Capital =

Energy =

Last year

4000

350

15000

3000

Now

4100

375

18000

2600

Labor productivity (Units/hr) =

11.4286

10.9333

Capital productivity (units/$) =

Cost of capital =

Energy productivity (Units/KWH) =

0.2667

3000

1.3333

0.2278

3600

1.5769

4200

15000

1200

8400

0.4762

4500

18000

1040

9140

0.4486

0.4762

8610

530

Labor cost = Hours x $12 =

Capital $ =

Energy $ = $0.40 x Energy =

Total input $ =

Multifactor productivity (Units/$) =

Target productivity =

Target input = 4100/0.4762 =

Reduction in input needed = 9140 – 8610 =

#2

Number serviced

Dollar value/unit

Production in $

Labor hours = 3 workers x 8 hrs. =

Labor productivity = 1260/24 =

Multifactor productivity

Labor cost = 3x8x$12 =

Material =

Overhead =

Total input cost =

Productivity = 1260/538 =

5% improvement in MF productivity =

Target productivity after 5% improvement =

Input for improved productivity =

Reduction in input needed =

LM

10

50

500

24

52.50

$

$

$

$

288

200

50

538

2.3420

0.1171

2.4591

512.38

25.62

Change

-0.4952

Change %

-4.33%

-0.0389

-14.58%

0.2436

18.27%

-0.0276

-5.8%

R

W

2

3

200

120

400

360

per day

per hour of labor

1260

<-- Total $

= 288 + 200 + 50

per $ input

<-- Output/Productivity = 1260/2.4591

<-- 538 – 512.38

3. (a)

B

D

E

Start

A

I

G

C

F

H

J

Fin

ish

Task

A

B

C

D

E

F

G

H

I

J

Task

Start

A

B

C

D

E

F

G

H

I

J

Finish

a

4

2

8

1

6

2

2

6

4

1

m

7

8

12

2

8

3

2

8

8

2

t

ES

7

9

12

2

10

3

2

8

8

2

0

7

7

16

19

19

22

22

29

37

39

B

10

20

16

3

22

4

2

10

12

3

EF

0

7

16

19

18

29

22

24

30

37

39

t

7

9

12

2

10

3

2

8

8

2

LS

0

8

7

17

19

24

27

31

29

37

39

Variance

1.0000

64/36

256/36

64/36

4/36

LF

0

7

17

19

19

29

27

29

39

37

39

Slack

0

1

0

1

0

5

5

9

0

0

Critical

Critical

Critical

Critical

Critical

Critical path = A-C-E-I-J, Project completion time TE = 39

Variance for project completion time = 2p = 1 + 388/36 = 11.7778; p =3.4319

b. For P(T <=42), Z = (42 – 39)/3.4319 = 0.87, Table area = 0.80785, Probability = 0.80785

c. For P(T <=35), Z = (35 – 39)/3.4319 = -1.17, Table area = .879; Probability = 1 - .879 = 0.121

d. Z for 99% confidence = 2.325, T = 39 + 2.325(3.4319) = 46.98

4.

C

A

F

I

Finish

Start

G

B

D

H

E

Normal

Time

Crash

time

Normal

cost

Crash

cost

MCA

Crashing

cost/week

A

7

4

20000

38000

3

6000

B

8

5

50000

74000

3

8000

C

9

7

80000

110000

2

15000

D

8

8

30000

30000

0

E

9

8

10000

12000

1

2000

F

10

8

90000

124000

2

17000

G

5

5

25000

25000

0

H

10

8

32000

40000

2

4000

I

5

4

28000

35000

1

7000

Sum =

365,000

Activity

Paths

A-C-F-I

A-D-G-I

B-D-G-I

B-E-G-I

B-E-H

Path time

31

25

26

27

27

Predecessor(s)

A

A, B

B

C

D, E

E

F, G

Critical path

Normal project time = 31 weeks

Normal project cost = 365,000

Activity to crash = A – among the critical activities (A, C, F, I) the crashing cost/week for A is the smallest.

Weeks to crash = Minimum{MTR of A, Project time – time of second longest path}

i.e. = Minimum{3, 31-27} = 3

Project time after crashing A 3 weeks = 31 – 3 = 28 weeks

Project cost after crashing A = 365,000 + 3 x 6,000 = 383,000

5.

(a)

Activity

Successors(s)

A

C, D

B

D, E

C

F

D

G

E

G, H

F

I

G

I

H

Finish

I

Finish

(b)

F2

G2

C15

D18

E18

D21

C25

G19

F19

G16

G15

H15

B27

B2-C2

(E2-D2)/F2

B2-B15

Max(E15,E16)

D18+C18

Max(E18,E19)

Max(E22,E23)

Min(F21,F22)

G19-C19

Min(F18,F19)

Min(F17,F18)

F15-D15 or G15-E15

Sum(D2:D10)

B28

B29

Sumproduct(BG15:B23,G2:G10)

B27+B28

(c)

(d)

(e)

Solver Target cell for minimizing the project completion time = C25

Changing cell range = B15:B23

What are the Solver constraints?

B15:B23 <= F2:F10

B15:B23 = Integer (Optional)

6.

Month

Demand

(At)

Nov.

Dec.

Jan.

Feb.

Mar.

April

37

36

40

42

47

43

3-MA

Forecast

|Et|

|Et|/At

Et2

Weight

Weighted

3-MA

|Et|

|Et|/At

3

3

4

37.67

4.33

0.1031

18.7489

37.90

4.1

0.0976

39.33

7.67

0.1632

58.8289

39.60

7.4

0.1574

43.00

0

0.0000

0

43.40

0.4

0.0093

Forecast =

MAD =

4

44.00

MAPE =

8.88%

MSE

=25.8593

Forecast

=

MAD

= 3.97

43.90

7.

Period

1

2

3

4

5

Demand

13

21

28

37

25

Ft

Et

|Et|

16.00

-3.00

3.00

14.20

6.80

6.80

18.28

9.72

9.72

24.11

12.89

12.89

31.84

-6.84

6.84

F6 =

27.74

MAD =

7.85

Period

1

2

3

4

5

Demand

13

21

28

37

25

Ft

Et

16.00

-3.00

3.00

14.20

6.80

6.80

3.80

18.28

9.72

9.72

13.52

24.11

12.89

12.89

26.41

31.84

-6.84

6.84

19.57

Week

1

2

3

4

5

6

7

Sales

17

22

27

32

35

37

41

Tracking signal

|Et|

CFEt

CAEt

MADt

TS

-3.00

3.00

3

-1

9.80

4.9

0.78

19.52

6.51

2.08

32.41

8.1

3.26

39.25

7.85

2.49

8.

28

b

211

XY n X Y

X nX

2

a Y bX

2

b

XY

X2

17

1

n=

7

X2 =

140

44

4

X =

28

954

81

9

Y =

211

XY =

b=

128

16

=

4.0000

175

25

=

30.14

222

36

287

954

49

140

a=

954 7(4)(30.14)

3.9286

140 7(4) 2

a 30.14 3.9286(4) 14.4286

Regression equation: Ŷ = 14.4286 + 3.9286t

F8 = 14.4286 + 3.9286(8) =

45.8571

9.

Quarter

Year 1

Demand

Year 2

Year 3

Average

Index

3.9286

14.4286

MAPE =

8.81%

1690

940

2625

2500

1

2

3

4

1800

900

2900

2360

1850

1100

2930

2615

Overall average =

1780.00

0.8823

980.00

0.4857

2818.33

1.3969

2491.67

2017.50

1.2350

Year 3 sum =

8495

Annual demand for year 4 = 1.1 x 8495 = 9345

Demand/season = 2336

Forecast for year 4

Quarter

1

2

3

4

Average demand

2336

2336

2336

2336

Seasonal Index

0.8823

0.4857

1.3969

1.2350

Forecast

2061

1135

3263

2885

10.

Store

1

2

3

4

5

6

7

8

9

10

11

12

Sum =

X

24

30

(b)√

(c)

Sales (X)

7

2

6

4

14

15

16

12

14

20

15

7

132

Profits (Y)

15

10

13

15

25

27

24

20

27

44

34

17

271

Y

43.2923

52.8503

Estimated

profit

$ 4,329,230

$ 5,285,030

7159−5.0601(271)−1.593(3529)

12−2

Y2

225

100

169

225

625

729

576

400

729

1936

1156

289

7159

= 4.0738

12(3529)−(132)(271)

√[12(1796)−1322 ][12(7159− 2712 ]

r2 = 0.8403

X2

49

4

36

16

196

225

256

144

196

400

225

49

1796

XY

105

20

78

60

350

405

384

240

378

880

510

119

3529

=

6576

7173.8258

=0.9167

n=

X =

Y =

=

=

12

1796

X2 =

132

XY = 3529

271

7159

Y2 =

11

b = 1.5930

22.5833

a = 5.0601

Ft = 5.0601 + 1.593 X

11.

Complaint

Food taste

Table/utensils dirty

Slow service

Food temperature

Too expensive

Order mistake

Frequency

80

47

16

9

4

2

158

%

Cum %

50.6%

29.7%

10.1%

5.7%

2.5%

1.3%

100.0%

50.6%

80.4%

90.5%

96.2%

98.7%

100.0%

Frequency

Pareto Chart: Complaints

90

80

70

60

50

40

30

20

10

0

To cover 80% of complaints, Food Taste and dirty utensils must be addressed first.

12.

100.0%

90.0%

80.0%

70.0%

60.0%

50.0%

40.0%

30.0%

20.0%

10.0%

0.0%

13.

Sample

1

2

3

4

5

6

7

8

9

10

R

1.0

0.3

0.5

0.7

0.2

0.4

0.5

0.8

0.3

0.3

33.8

34.4

34.5

34.1

34.2

34.3

33.9

34.0

33.8

34.0

𝑋̿ = 34.1

n=6

0.483

A2 =

A2

=

0.2415

LCL = 𝑋̿ - A2 =

UCL = 𝑋̿ + A2 =

33.86

34.34

D2 =

0

D3 =

2.004

LCLR =

0

UCLR =

1.002

= 0.5

The process is not in control, since the 𝑥̅ values for samples 1, 2, 3, and 9 fall outside the control

limits. Although all the sample ranges fall within 0 and 1.002, the assignable causes should be

investigated and eliminated.

14.

Use c-chart

𝑐̅ = total defects/number of sheets = 1.8

UCLc = 1.8 + 3 1.8 = 1.8 + 4.02 = 5.825

LCLc = 1.8 - 3 1.8 = 1.8-4.02 = converts to zero

Sheet number 1

has too many flaws; investigate the cause.

0.03 (1−0.03)

15. LCLp = 0. 03 −

3√

100

0.03 (1−0.03)

LCLp = 0. 03 + 3√

100

= 0.03 - (3 * 0.017) = -0.02; can’t be zero, so, round to 0

= 0.03 + (3 * 0.017) = 0.081

Limits are LCL = 0 and UCL = 0.081. All six points are in control; there is no pattern or trend in

the data.

= 1.2; (b) LCLc = 1.2 – 3 √1.2 = -2.0862, or zero

UCLc = 1.2 + 3 √1.2 = 4.49.

16.

(a)

17.

LSL = 5.9 mm, USL = 6.1 mm.

Cpk = min{(6.1-6.04)/(3*0.02), (6.04 - 5.9)/(3*0.02) = min{1.00, 2.33} = 1.

Cp = (6.1 – 5.9)/(6*.02) = 1.67

Since Cpk is < 1.333 the process is not capable. Since Cp = 1.67, the process variability is small enough to be

within the desired specification range. Therefore, the process needs to be centered to achieve a Cpk of at least

1.33.

18.

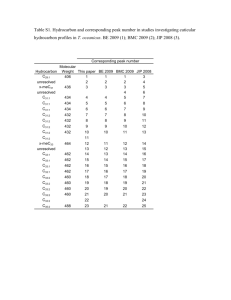

Pd

0.00

nPd

0.00

Pa

1.000

0.01

0.02

0.03

0.04

0.05

0.50

1.00

1.50

2.00

2.50

0.910

0.736

0.558

0.406

0.288

0.06

0.07

0.08

0.09

0.10

3.00

3.50

4.00

4.50

5.00

0.199

0.137

0.092

0.061

0.040

For AQL = 2%, Pa= 0.736

i.e., Producer’s risk = 1 – 0.736 = 0.264

For LTPD = 14%, nPd = 50 x 0.14 = 7.0,

Pa from Poisson table = 0.007

i.e. Consumer’s risk = 0.007

OC-Curve for the sampling plan, n=50, C = 1

1.0

0.9

P(Accepting lot)

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

0.00

0.02

0.04

0.06

0.08

0.10

0.12

Pd (% of defectives in the lot)

Pd

0.00

0.01

0.02

0.03

0.04

0.05

0.06

0.07

0.08

0.09

0.10

Pa

1.000

0.910

0.736

0.558

0.406

0.288

0.199

0.137

0.092

0.061

0.040

AOQL = 0.01507

AOQ

0.00000

0.00819

0.01325

0.01507

0.01462

0.01294

0.01075

0.00860

0.00662

0.00494

0.00360

Percent defective accepted

(d)

AOQ

0.02000

0.01500

0.01000

0.00500

0.00000

0.00

0.05

0.10

Pd

0.15

19.

N=

n=

c=

Pd =

5000

200

5

3%

nPd =

Pa =

AOQ =

AOQ =

6

0.446

<-- from Poisson table

.03(.446)(5000-200)/5000

0.0128448 i.e. = 1.28%