2MET 203 optical metallography

advertisement

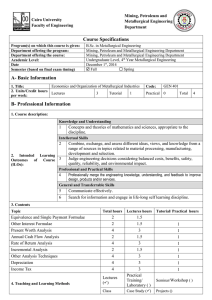

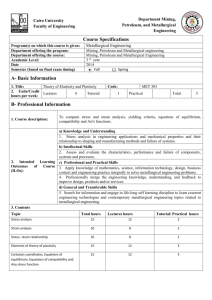

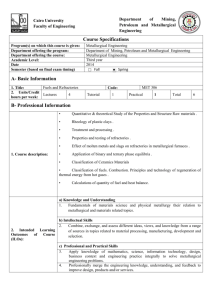

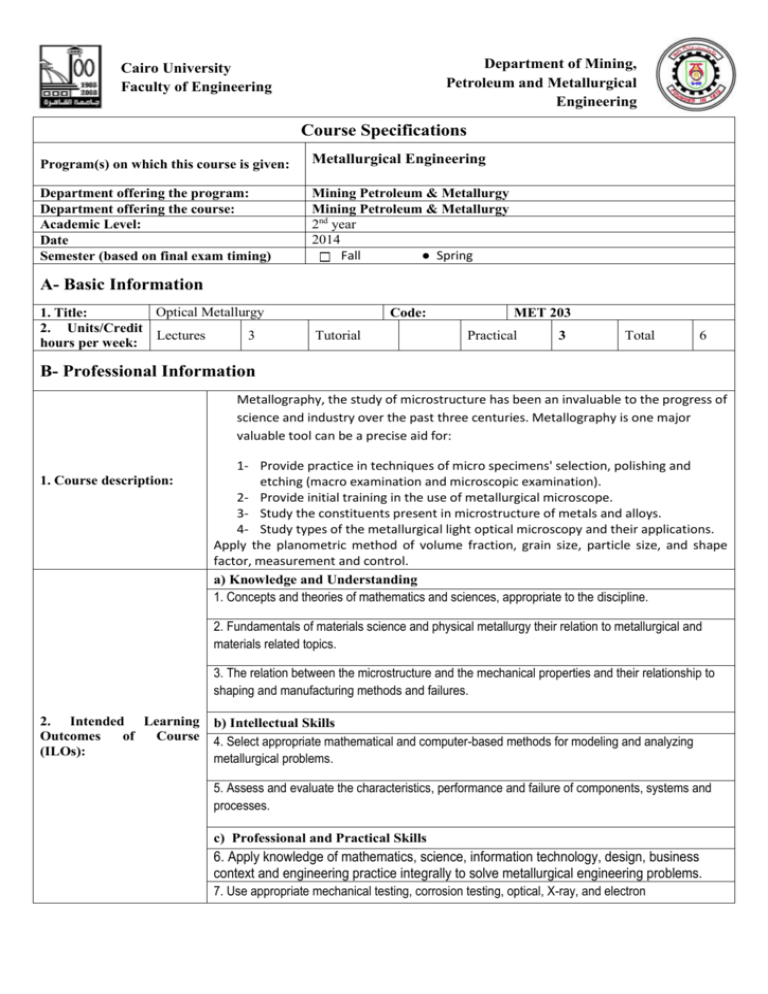

Department of Mining, Petroleum and Metallurgical Engineering Cairo University Faculty of Engineering Course Specifications Program(s) on which this course is given: Metallurgical Engineering Department offering the program: Department offering the course: Academic Level: Date Semester (based on final exam timing) Mining Petroleum & Metallurgy Mining Petroleum & Metallurgy 2nd year 2014 Fall ● Spring A- Basic Information Optical Metallurgy 1. Title: 2. Units/Credit Lectures 3 hours per week: Code: Tutorial MET 203 Practical 3 Total 6 B- Professional Information Metallography, the study of microstructure has been an invaluable to the progress of science and industry over the past three centuries. Metallography is one major valuable tool can be a precise aid for: 1. Course description: 1- Provide practice in techniques of micro specimens' selection, polishing and etching (macro examination and microscopic examination). 2- Provide initial training in the use of metallurgical microscope. 3- Study the constituents present in microstructure of metals and alloys. 4- Study types of the metallurgical light optical microscopy and their applications. Apply the planometric method of volume fraction, grain size, particle size, and shape factor, measurement and control. a) Knowledge and Understanding 1. Concepts and theories of mathematics and sciences, appropriate to the discipline. 2. Fundamentals of materials science and physical metallurgy their relation to metallurgical and materials related topics. 3. The relation between the microstructure and the mechanical properties and their relationship to shaping and manufacturing methods and failures. 2. Intended Learning b) Intellectual Skills Outcomes of Course 4. Select appropriate mathematical and computer-based methods for modeling and analyzing (ILOs): metallurgical problems. 5. Assess and evaluate the characteristics, performance and failure of components, systems and processes. c) Professional and Practical Skills 6. Apply knowledge of mathematics, science, information technology, design, business context and engineering practice integrally to solve metallurgical engineering problems. 7. Use appropriate mechanical testing, corrosion testing, optical, X-ray, and electron metallographic, and chemical analysis methods for metals and alloys. d) General and Transferable Skills 8. Search for information and engage in life-long self learning discipline to learn ccurrent engineering technologies and contemporary metallurgical engineering topics related to metallurgical engineering. 3. Contents Topic The optical microscope Total hours 12 Lectures hours 3 Tutorial/ Practical hours Preparations of specimens for light Metallography 9 Optical examination of standard macro and microstructures covering grains structures, solidification structures, wrought structures, phase distribution, eutectics, peritectic and solid state transformations products 21 Lenses and lens aberrations 22.5 1.5 Resolution and depth of focus 7.5 1.5 Illumination systems 3 3 Polarizing microscopy 3 3 High temperature microscopy 3 3 Phase contrast and interferometry 3 3 Mid-Term 3 3 Elements of quantitative metallography 15 15 6 Metallographic Measurements 3 Elements of photography 3 Oral and Prcticle Exam Teaching and learning Methods 6 3 3 6 3 3 Class Activity (● ) E-learning ( ) .Assessment Schedule Case Study (● ) Assignments /Homework (● ) Week Projects ( ) Other: practice work in lab -Assessment 1; Class test Week on a weekly basis -Assessment 2; Project Assignment Week 5 -Assessment 3; Presentations Week 13 -Assessment 3; Midterm Exam Week 8 -Assessment 4; Final Exam End of the term Weighting of Assessments -Mid-Term Examination -Final-term Examination -Project -Class Test -Presentation -Total 15% 60% 10% 5% 10% 100% 6. List of References 6.1 ASM Handbook vol. 1, 2, and 9, ASM international 10th edition (1990). 6.2 Metallography- Principles and practice, Co. F. Vander Voort 1st edition, Mc Graw-Hill publisher (1984) 6.3 Metallographic Polishing by Mechanical Methods, L. E. Samules 4th edition, ASM international publisher (2003) 6.4 Metallographic Etching G. Pet3ow, 2nd edition, ASM International publisher (1999) 6.5 Metallography and Microstructure of Ancient and Historic Metals by David A. Scott (1991) 6.6 Metallographic Handbook by Donald c. Zipperian (2011) 7. Facilities Required for Teaching and Learning . Board, Overhead projector and Data show Tools in optical metallography lab Prof. Dr. E. M. Elbana Course Coordinator: Head of Department: Prof. Dr. E. M. Elbana