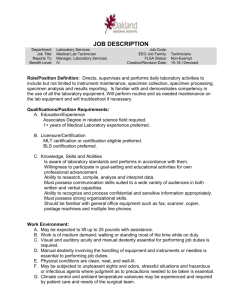

Director of Quality Control

advertisement

Director of Quality Control Palmer Candy Company- Sioux City, IA Classification Exempt Reports to President Date 10/23/15 JOB DESCRIPTION Summary/Objective This position is responsible for maintaining a company quality assurance system and team that promotes customer satisfaction, food safety and that positively impacts the financial performance of Palmer Candy Company. Essential Functions Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions. Initiates and implements quality improvement activities as appropriate to raise the food safety performance of the company’s product lines. Educates and trains Team Members on GMPs and food related issues. Serves as the primary quality control resource for problem identification, resolution, and loss. Manages quality control personnel on a day-to-day basis. Designs, implements and documents procedures for process control, process improvement, testing and inspection. Monitors and continually updates required FDA policies and programs. Establishes and implements metrics (process capability, control charts, measurement quality) for monitoring system effectiveness and to enable team members to make sound product quality decisions. Performs root-cause analysis and other problem solving activities to identify effective corrective actions and process improvements. Establishes collection and analysis systems of statistical data to predict trends that will affect improvement of product quality. Analyzes customers’ product specifications to confirm quality implementation in production environment. Develops quality planning methods for all product lines. Develops process certification standards and assist in process certification. Monitors vendor performance and establish criteria and rating system for critical vendors. Interacts with customers to identify opportunities to improve quality and establish feedback with manufacturing and development personnel. Monitors and updates customer driven websites which require entry of product specifications and other information. Oversees calibration and testing programs. Reports to management on quality issues, trends and losses. Reviews suppliers and establishes supplier quality requirements. Monitors and coordinates company's Kosher certification. Participates in internal and external quality audits. Prepares the company for annual SQF or GFSI audit. Develops and maintains documentation of ongoing worksite sanitation and maintenance. Interfaces with supplier and customer quality representatives concerning problems with quality control and assure that effective corrective action is implemented. All other reasonable duties, as assigned. Competencies Communication Proficiency Decision Making Organizational Skills Problem Solving/Analysis Results Driven Technical Capacity Time Management Supervisory Responsibility This position manages all employees of the department and is responsible for the performance management of the employees within that department. Work Environment This job operates in a clerical, office, as well as a manufacturing setting. This role routinely uses standard office equipment such as computers, phones, photocopiers, filing cabinets and fax machines. While performing the duties of this job, the employee is frequently exposed to odors, fumes, dust or airborne particles, moving mechanical parts and vibration. The noise level in the work environment and job sites can be loud. Possible exposure to minor burns or cuts. Physical Demands The physical demands described here are representative of those that must be met by an employee to successfully perform the essential functions of this job. While performing the duties of this job, the employee is regularly required to talk or hear. The employee frequently is required to stand; walk; use hands to finger, handle or feel; and reach with hands and arms. The employee is occasionally required to sit; climb or balance; and stoop, kneel, crouch or crawl. The employee must occasionally lift and/or move up to 35 pounds. Specific vision abilities required by this job include close vision, distance vision, color vision, peripheral vision, depth perception and ability to adjust focus. Position Type and Expected Hours of Work This is a full-time position, and typical work hours and days are Monday through Friday, 8:00 a.m. to 5 p.m. Occasional evening and weekend work may be required as job duties demand. Travel Travel is primarily local during the business day. Required Education and Experience Bachelor’s degree in Food Science, Food Microbiology or similar field preferred. Five plus years of relevant experience in a food manufacturing environment with FDA regulated industries. HACCP certification required Experienced in implementing GMP's in a manufacturing environment; ability to achieve SQF Practitioner status. Other Duties Please note this job description is not designed to cover or contain a comprehensive listing of activities, duties or responsibilities that are required of the employee for this job. Duties, responsibilities and activities may change at any time with or without notice.