Tushar Sitaram Patil

advertisement

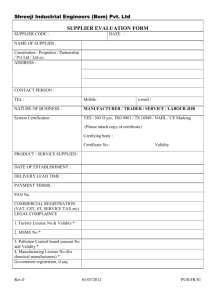

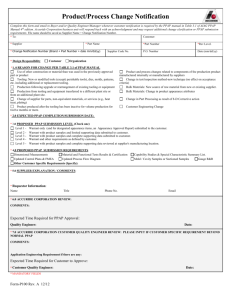

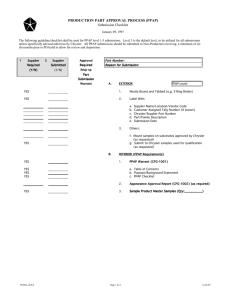

RESUME Tushar Sitaram Patil E-mail:- tshrpatil@yahoo.co.in Contact No. :- +91 9822530760 CAREER OBJECTIVE To work with commitment in a well organized company, where my skills will be useful for the development of company and to boost my career to the peak. PROFILE SUMMERY Implementation of ISO/TS 16949, Internal audit, HSE, quality control, quality assurance, supplier & inhouse process and product audit, APQP, PPAP, FMEA, Control Plan, standard room, calibration, measurement system analysis (MSA), statistical process control (SPC), GD&T, SAP-QM Module, Lean Six Sigma Green Belt, Warranty Analysis, 8D, MMA, MSES Experience in casting, forging, machining, sheet metal, injection molding, rubber commodity Hands on measuring instruments like roundness tester, profile projector, contour measuring instrument, roughness tester, air gauges and all basic instruments and gauges Expertise in root cause analysis, resolving customer complaints(8D), corrective & preventive action, receiving, In- process Inspection and final inspection, 7QC tools, Kaizen, 5S PPAP Preparation for OEM & Supplier’s PPAP Approval, MSES, MMA Handled Greenfield project set up PROFESSIONAL CERTIFICATION Certified in Calibration of measuring instruments & gauges from Reliance Calibration Laboratory (NABL) in 2004 Certified in Measurement Uncertainty from CETE in 2010 Certified in Internal Auditor for ISO 9001:2008 from BUREAU VERITAS in 2012 Certified in Lean Six Sigma Green Belt from AIQM Accredited by ASCB(E) UK in 2014 Certified in MPPAP by Mahindra & Mahindra in 2014 AREA OF EXPERTISE Implementation & Maintenance of ISO/TS 16949, HSE Warranty & Field Analysis Customer complaint resolving(8D) & tracking Customer Audit, MMA, MSES, Result indicator sheet monitoring, Follow up Audit supplier Quality audit (Process & Product) at supplier end as per plan APQP Documentation Responsible for APQP, PTR, PPAP, Process Capability Studies, Capacity Analysis for Program Launch Readiness Quality Planning Hands on experience in Quality tools PFMEA, Control Plan, MSA, SPC, 7QC Responsible for Part Development, monitoring at supplier End Coordinator for change management with development team Get PPAP sign off from customer Supplier PPAP approval In-house rejection and rework monitoring Supplier rejection monitoring Reduce Customer, In-house & Supplier PPM Reduce COPQ Gauge Planning, Process Improvement(Poka-yoke, Kaizen) KEY ACHIEVEMENTS Implementation of ISO 9001:2008 & ISO/TS 16949:2009 Implementation of HSE standards Reduction in PPM level ORGANIZATIONAL EXPERIENCE PRABHA ENGINEERING PVT. LTD.:-PUNE Designation: Asst. Manager QA Reporting To: Plant Head Company Profile: From Jan.2013 Till Date Prabha is a manufacturer of wiper motors and windscreen washer units in the domestic Automotive market and internationally Prabha is known for its expertise in DC Motors for automotive & non-automotive applications. Customers: AMW, Tata Motors, Mahindra & Mahindra, Force Motors, Piaggio, Atul Auto, Thomson CAMERON MANUFACTURING INDIA PVT. LTD.: Greenfield Project in PUNE Designation: Project Quality Coordinator From Jun.-2011 To Jan.2013 Reporting To: Manager India Operation Company Profile: Cameron is a leading provider of flow equipment products, systems and services to worldwide oil, gas and process industries. Leveraging its global manufacturing, engineering and sales and service network, Cameron works with drilling contractors, oil & gas producers, pipeline operators, refiners and other process owners to control, direct, adjust, process, measure and compress pressures and flows. PERFECT ENGINE COMPONENT PVT. LTD.:-PUNE Designation: Sr. Engineer QA From Sept.-2006 To May- 2011 Reporting To: Manager QA Company Profile: It is a manufacturer of Inlet& Exhaust Valves ForI.C.Engine supplies to Tata Motors, Eicher, Cummins India, Bajaj, John Deere, Ashok Leyland. PRESFIELD ENGINEERS PVT. LTD.:- PUNE Designation: Engineer QA From Jun.-2002 To Sept.-2006 Reporting To: Plant Head Company Profile: The Company is engaged with precision pressed parts Bosch Chassis System India Limited and Keihin Fie India Limited. VISIT ABROAD Technical Training of the Differential Pressure Indicators, Differential Pressure Switches in Bognor Regis, United Kingdom in Nov’2011. SAP-QM Module Training in Royal Tunbridge Wells, United Kingdom in May 2012 ACADEMIC CREDENTIALS D.M.E (Mechanical Engineering-3 year’s course)with II class from Govt. College Latur H.S Exam. (10+2 level) with 1st class from KKW college Nashik Secondary Exam. (10 level) with Dist. from JanataVidyalaya, Nashik PERSONAL DETAILS Date Of Birth: 11th May 1979 Address 1) 2) Date: Married : Flat No. 21, B-2, Nirmitee Nest, Sr. No. 40/1, Manajinagar, Narhe, Pune-41. REFERENCE Mr. Milind Attarde (Manager India Operation) M/s Cameron Manufacturing India Pvt. Ltd., Punei Contact No.: 9822431686 Mr. Prasad Diwan (Manager QA) M/s Williams Control India Pvt. Ltd., Pune Contact: 9881374445 Tushar S. Patil