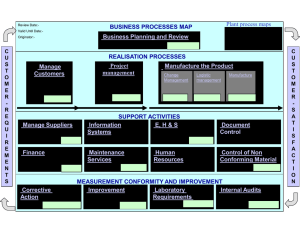

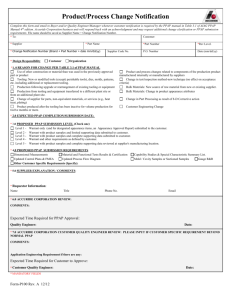

S.VINOTH Senior Analyst, HCL, Madurai ENGINEER QUALITY Having 8 years of experience in quality engineering, New Product Quality (NPD), Quality Inspection (QI-NPD) Customer Quality Assurance (CQA-NPD), Supplier Quality Assurance (SQA-NPD), and lean manufacturing. Deliver quality controls and enhancements to proactively address problems and improve product quality, manufacturing flow, customer satisfaction and bottom-line results. CONTACT vinothsathiyavan@gmail.com +91-9047061517 ABOUT ME Comprehensive knowledge of Quality Management Tools Advanced Product Quality Planning (APQP) Production Part Approval Process (PPAP) Statistical Process Control (SPC), Measurement System Analysis (MSA) 8+years of competitive experience in Quality assurance (QA) in automobile industry. Good work Hands-on experience in working with instruments like 2D Height master, ethics with excellent Profile Projector, Vision Unit, Contour, Finish Tester & Micrometer, etc. communication and interpersonal skills. Excellent motivational leadership skills in a fast-paced environment. Capable to delve into the new leading technologies. Ability to work well in both a team environment and individual environment. SOFTWARE KNOWS; MS Office Catia Mini tab REPORTING STRUCTURE; PROFFESIONAL EXPERIENCE Senior Quality Analyst NPD QA Head My role (PRICOL) HCL Technologies Ltd Mar 2021 to Till date | Madurai (India). Quality Analyst -J&J (All Bu’s) Quality Inspectors Supplier quality engineers Core Quality person in medical device development cycle –Tech documentation, Risk analysis, Medical QMS, control plan, Production process control. Achievement’s While investigating the license to avoid manual verification (variant description field), Macro enabled automatic button provided. Potential cost saving up to $46326.75 per quarter Products handled, Oil Pump PROFFESIONAL EXPERIENCE Pricol Limited. Dec 2016 to Mar 2021 | Coimbatore (India). Quality Assurance. 1. Customer- Quality: Fuel Pump & Water Pump 1. Customer Satisfaction Surveys: Conducting surveys to gather customer feedback and insights on their experience with a company's products or services. This information can be used to identify areas of improvement in customer service, quality assurance, and product development. 2. Quality Audits: Conducting regular audits of manufacturing and service processes to ensure that they meet industry standards and regulations. Quality audits can help identify areas of improvement and prevent defects or safety issues. 3. Customer Complaint Resolution: Developing and implementing effective processes for addressing customer complaints in a timely and professional manner. This includes identifying the root cause of the problem, finding a solution, and following up with the customer to ensure their satisfaction. 4. Product Testing and Certification: Conducting rigorous testing of products to ensure that they meet safety and quality standards set by regulatory bodies. This includes obtaining certifications such as ISO 9001 and IATF 16949, which demonstrate a company's commitment to quality. 5. Continuous Improvement: Continuously reviewing and improving processes, products, and services to meet changing customer needs and expectations. This includes implementing lean manufacturing principles, reducing waste, and improving efficiency. Hydraulic CTS Cylinder 6. Employee Training and Development: Providing ongoing training and development opportunities to employees to improve their customer service and quality assurance skills. This includes training on new products, processes, and industry standards. 2. NPD – Quality: Product Development Developed product quality standards based on in-house quality requirement Hydraulic CTS Pump instruct product quality requirements to team members Assigned responsibility to subordinates based on inspection requirements Hydraulic CTS Latch Reviewing of inspection reports on daily basis Monitoring part wise rejection details (In house) & conducting rejection analysis meeting on daily basis to reduce rejection PPM Customers handled, Reviewing of inspection reports on daily basis Monitoring part wise rejection details (In house) & conducting rejection analysis meeting on daily basis to reduce rejection PPM Conducting RCA for field failures & customer raised complaints to eliminate the potential cause of non-conformity by using QC Tools, Why Why analysis, G8D reports Providing awareness about customer complaints to subordinates Conducting SPC (Statistical Process Control) & MSA study Coordinating & maintaining of standard room (Calibration, Measuring equipment monitoring) activities 3. NPD – Quality: Product Development Ensure to achieve desired Design, Quality & Delivery goals of NPD through APQP process compliance for, Oil pump, Auto-Decomp unit, Chain tensioner, water pump, Hydraulic products & Fuel pump Module Product, Design & Process Verification and validation, Product reliability to ensure adherence as per APQP Customer PPAP compliance before SOP - Providing Pre-launch PPAP documents (Related to Quality function ) and Conducting initial process trials & evaluation Reduction of COQ (Cost of Quality) by identifying & implementation of qualifying gauges at Inward & In-process area and conduct MSA study to ensure proper measurement system. Ensuring First Time Right at customer end for the sample submission during T1, T2 samples & Pilot lot Customer complaint handling at development stages & root cause analysis in 8D approach with involvement of CFT Conducting product Dis-assembly test and ensuring action before SOP. Conducting process capability study for new process, Internal PPAP trails and suggesting Improvements and initiating actions PPAP sign off with plant QE team and handover the product by ensuring PPAP documents. Coordinates with Plant QE team and PDE team during Customer PPAP audits. Monitors Customer Line issues & warranty issues for part, process & design related defects up to 6 months from SOP and Warranty issues for design related defects up to 2 years from SOP PREVIOUS EXPERIENCE PERSONAL PROFILE: Graduate Engineering Trainee TVS motor company pvt. ltd June 2014 to Sep 2016 | Hosur (India), NPD- Quality (Motorcycle & mopeds) Father’s Name: B.Sathiyavan Date of Birth : 31.05.1993 Part approval process: Gender : Male Part approval for supplier parts during Alpha, Beta & QP phases in New Product Development (UP.162, UP.177, and NP.112). Languages Nationality : English, Tamil. : Indian 1)Dimensional 2)Material 3)visual 4) packing standards Marital Status: Married SPTR (Significant Product Trail Run): Religion During QP stage of the project we have Conduct the SPTR audit at supplier location & verify the all PPAP files at supplier location : Hindu Problem analysis: ADDRESS : 5th block, Periyasamypuram(post) Vilathikulam (tk) pachiyapuram. Tuticorin – 628906 Analyse and provide solution for problems (related to supplier) identified during Alpha, Beta & QP stages by using QC tools. Line stopper PPFR complaints Inspection plan & control: During QP stage we have to check the supplier parts in all aspects for SUC up to 5000 vehicles Warranty analysis: REFERENCES: Mr.C.Prabhakaran Manager (Quality Assurance) Pricol Ltd, CBE, . +91- 9003910947 Mr.R.Sathyakumar Assistant manager (Quality Assurance) TVS Motors ltd Harita, Hosur. +91-8220013627 In order to find the past product parts failure modes, i have collected the field return parts & analysed. EDUCATION B.E. Mechanical Engineering National engineering college, Kovilpatti, Tamilnadu. 2011 to 2014 CGPA: 8.04 Diploma Mechanical Engineering Lakshmi ammal polytechnic college, Kovilpatti, Tamilnadu. 2008 to 2011 GPA: 87 HOBBIES : Long bike drives Audio books I hereby declare that the information furnished above is true to the best of my knowledge S.VINOTH