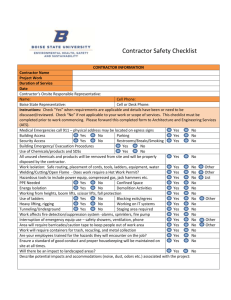

Detailed Specification

advertisement