Modeling - Sustainable Food Chains Platform

advertisement

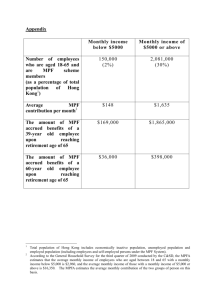

Modeling an inventory routing problem for perishable products with environmental considerations and demand uncertainty We addressed a generic inventory routing problem (IRP) that consists of a single supplier (depot) and a number of customers. Under the Vendor Managed Inventory (VMI) policy, the supplier has to make three simultaneous decisions: when to deliver to each customer, how much to deliver to each customer each time it is served, and how to combine delivery to customers into vehicle routes. The problem is to determine the routes and quantity of shipments in each period in such a way that the total cost comprising routing, inventory and waste costs is minimized. We developed a comprehensive chance-constrained programming model (MPF) for the multiperiod IRP that accounts for perishability, explicit fuel consumption and demand uncertainty. The proposed model manages relevant KPIs of total energy use (emissions), total driving time, total routing cost, total inventory cost, total waste cost, and total cost simultaneously. To the best of our knowledge, the model was unique in using a comprehensive emission function and in modeling waste and service level constraints as a result of uncertain demand. To present the benefits of including perishability and explicit fuel consumption considerations in the model, we derived three additional models from the proposed model: model without perishability and explicit fuel consumption concerns (M), model with explicit fuel consumption concern (MF) and model with perishability concern (MP). Additionally, we proposed a simulation model to evaluate the solutions of these models in terms of inventory and waste performances, and to check whether these solutions are feasible. A case study was provided to present an implementation of the proposed model, and its variations described above, on the fresh tomato distribution operations of a supermarket chain operating in Turkey. Findings Our analysis on different scenarios showed the consequences of perishability and/or explicit fuel consumption ignorance. The models M and MF could not meet the desired service levels in all scenarios due to the perishability ignorance which resulted in relatively higher product wastes. On the contrary, accounting for the perishability allowed MP and MPF to satisfy the service levels in all scenarios. MPF provided the least cost solutions in all scenarios. According to the optimization results, MPF can achieve average savings in total cost by 24.3% compared to M, 20.5% compared to MF and 0.9% compared to MP . In the experiments, we successively changed the values of the following problem parameters: the demand means, coefficient of variations, fixed shelf lives, holding costs and service levels. It appeared that the added value of MPF compared to the other model variations in terms of total cost changes according to the parameter values. For instance, the total cost gap between M and MPF solutions increased as coefficient of variation or service level increases and decreased as fixed shelf lives or holding cost increases. The use of a more environmentally-friendly objective function (in model M’PF) showed that 2% decrease in total emissions can be obtained in return for a 25.2% significant total cost increase. The proposed model also give users the opportunity to exploit the trade-offs among sustainability KPIs through using different model variations. 1 2