NatProt(Hii)final - Spiral

advertisement

Preparation of Dicationic Palladium Catalysts for Asymmetric Catalytic Reactions.

Andrey E. Sheshenev, Alexander M. R. Smith and King Kuok (Mimi) Hii*

Department of Chemistry, Imperial College London, South Kensington, London SW7 2AZ, U.K.

ABSTRACT

The synthesis of Pd(OTf)2∙2H2O is described. This was used to generate two different types of chiral

dicationic palladium complexes for highly enantioselective addition of aromatic amines to unsaturated conjugate alkenes, furnishing optically active N-arylated -amino acid derivatives, which

are valuable synthetic intermediates for the synthesis of biologically active molecules and

peptidomimetics. The use of these catalysts in the enantioselective aza-Michael addition of aromatic

amines is demonstrated.

INTRODUCTION

Dicationic (diphosphine)palladium(II) complexes are widely used in asymmetric catalysis, and have

been shown particularly to have broad generality for the functionalisation of chelating Michael donors

containing enolisable carbon pronucleophiles (e.g. -ketoesters, malonate esters, silyl enol ethers),

where stereogenic C-C,1-12 C-N,13 C-F14-20 and C-O21,22 bonds can be constructed. On the other hand,

these dicationic palladium complexes are also one of the most effective catalyst systems for the

conjugate addition of aromatic amines to chelating Michael acceptors.23-29 Utilisation of these

catalysts in other type of reactions (with more limited reaction scope) includes hydroamination,30,31

Friedel-Crafts,32 as well as [2+2]33 and [4+2]34 cycloaddition reactions. Compared with other

transition metal-based Lewis acid catalysts, the dicationic palladium complexes are much more stable

towards air and moisture, and can generally be employed in lower catalytic loadings.

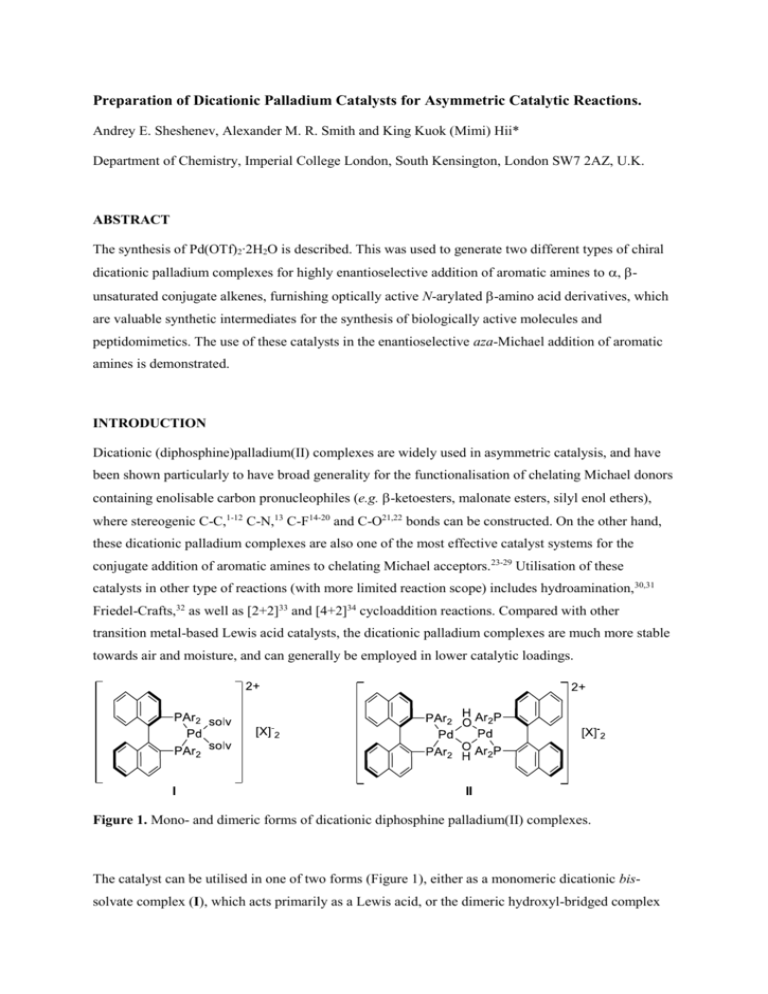

Figure 1. Mono- and dimeric forms of dicationic diphosphine palladium(II) complexes.

The catalyst can be utilised in one of two forms (Figure 1), either as a monomeric dicationic bissolvate complex (I), which acts primarily as a Lewis acid, or the dimeric hydroxyl-bridged complex

(II), which has dual Lewis acid-Bronsted base properties. The bis(aqua) complex of the

bis(trifluoromethanesulfonate) salt (solv = H2O, X = CF3SO3) is, by far, the most typical example,

although the nature of the coordinated solvate (solv = CH3CN, or a mixture of H2O and CH3CN) and

counteranion (X = BF4,11 SbF633) can be varied, and can be interchanged.34 The coordinated water

molecule can be easily deprotonated to form the dimeric complex II. Complexes of other congeners

of BINAP, such as tol-BINAP, SEGPhos, etc., are also reported, and are known to be more effective

for certain catalytic reactions.8

A common route to dicationic palladium(II) complexes uses silver salts to abstract halides from the

corresponding [(diphosphine)PdCl2] complex in wet acetone9 or acetonitrile,30 but the method has

drawbacks, namely, the preparation requires the addition of at least two equivalents (often in excess)

of the silver salt to the corresponding [(diphosphine)PdX2] complex (where X = Cl or Br). As a result,

careful and/or repeated recrystallisation of the resultant complex is required to remove all traces of

silver salt, which may also be catalytically active, inducing a competitive formation of racemic

products, compromising the enantioselectivity of the reaction.

In 1994, the preparation of Pd(OTf)2∙2H2O was described by Murata and Ido,35 by the reaction of

palladium(II) salts with trifluoromenthanesulfonic (triflic) acid, who also showed that they can be

used as effective catalyst precursors for the synthesis of [(diphosphine)Pd(OTf)2] complexes.

However, only achiral phosphine ligands were used, and consequently, asymmetric catalysis was not

demonstrated. We have subsequently shown that this palladium salt can be used to generate chiral

catalyst from chiral diphosphines, and demonstrated their utility in the asymmetric aza-Michael

reactions, either as a catalyst precursor, to generate the complexes in situ, or isolated complexes.26

Herein, we will describe the preparation of Pd(OTf)2∙2H2O (1) in detail, from commercially available

reagents; we will also describe how it can be used to generate [(R-BINAP)Pd(OH2)2][OTf]2 (2) and

[(R-BINAP)Pd(µ-OH)]2[OTf]2 (3) complexes, and the examples of how they can be employed to

attain highly enantioselective Michael addition of aromatic amines to N-alkenoyl carbamates.

__________________________________________________________________________________

BOX 1 REPRESENTATIVE EXAMPLE OF THE USE OF 2 AND 3 IN AZA-MICHAEL

ADDITION REACTIONS

Figure 2. Enantioselective addition of an aromatic amine to an N-alkenoyl carbamate.

Catalyst 2 can be used in the addition of non-nucleophilic aromatic amines to -unsaturated

Michael acceptors containing 1,3-dicabonyl chelating moieties, such as N-alkenoyl oxazolidinones,23

carbamates24 or imides36 (Protocol A). On the other hand, for the addition of nucleophilic aromatic

amines, the reaction is more effective when the amine is employed as a salt, in combination with

catalyst 3 (Protocol B),25,28,29 to provide a buffered environment, where catalyst deactivation by amine

binding to the Lewis acidic centre can be minimised.

Protocol A

1 Weigh out methyl (2E)-but-2-enoylcarbamate (0.20 g, 1.40 mmol) and catalyst (2) (0.045 g, 0.042

mmol, 3 mol %), place them into a reaction tube equipped with a magnetic stirring bar, and purge the

tube with nitrogen.

2 Add dry THF (3.5 mL) to the tube via syringe under nitrogen. A yellow solution is formed.

3 Add a solution of aniline (0.13 g, 1.40 mmol) in dry THF (3.5 mL) using a syringe pump (addition

speed 0.2 mL/h) under a nitrogen atmosphere (ambient temperature). When the addition is complete,

the reaction mixture is stirred for a further 3 h. The colour of the reaction mixture turns deep-orange

by the end of the reaction.

<CRITICAL STEP> Fast addition of aniline can cause significant yield deterioration due to the

deactivation of the catalyst.

4 Transfer the reaction mixture into a round bottom flask (50 mL) and concentrated to dryness using a

rotary evaporator.

<CRITICAL STEP> Do not heat the water bath over 35 °C, to avoid possible racemisation of the

product.

5 Pack a chromatography column (D 35 mm, L 300 mm) with 25 g of silica using a mixture of

hexane/ethyl acetate (3:2 v/v) as eluant.

6 Dissolve the crude product in the eluant and load it onto the packed column.

7 Add a layer of quartz sand (5 mm) on top of the column to prevent drying.

8 Elute the column under the atmospheric pressure; collect 5 mL fractions.

9 Analyse the contents of the collected fractions by thin-layer chromatography (using hexane:ethyl

acetate 3:2 v/v), Rf of the product is found at 0.30.

10 Combine fractions containing the product and evaporate using the rotary evaporator.

11 Dry the product under high vacuum.

Protocol B

1 Weigh out methyl (2E)-but-2-enoylcarbamate (0.20 g, 1.40 mmol), aniline triflate (PhNH2∙HOTf,

0.51 g, 2.10 mmol) and catalyst 2 (0.038 g, 0.021 mmol, 1.5 mol %). Place them into a reaction tube

equipped with a magnetic stirring bar, and purge it with nitrogen.

2 Add dry THF (2.8 mL) to the reaction tube via a syringe. A yellow solution is formed.

3 Stir the reaction mixture for 18 h at room temperature. The colour of the reaction mixture turns

orange by the end of the reaction.

4 Quench the reaction mixture by the addition of cold saturated aqueous NaHCO3 (5 mL) with ice

bath cooling.

<CRITICAL STEP> Quenching at room temperature result in a decrease in the enantiomeric purity of

the product.

5 Dilute the reaction mixture with ethyl acetate (10 mL), separate the aqueous layer and extracted it

with ethyl acetate (5 mL).

6 Successively wash the combined organic layers with brine (5 mL) and dry over MgSO4.

7 Filter the solution and remove the solvent using a rotary evaporator.

<CRITICAL STEP> Do not heat the bath over 35 °C to avoid possible racemisation of the product.

8 Purify the residual orange solid by column chromatography on silica gel as described above (steps

5-11).

<CRITICAL STEP> As 1.5 equiv. of aniline triflate is used, unreacted aniline can be recovered in

approx. 80% yield.

(3-Phenylaminobutyryl)carbamic acid methyl ester prepared by Protocol A: yield 76%, 93% ee;

prepared by Protocol B: yield 94%, 97% ee. The physical properties of the aza-Michael adduct are

dependent upon its optical purity. Racemic samples are found to have higher melting points than

optically active samples.37 In this case, the racemic and 93% ee samples appeared as solids (A and B,

figure 4), while the sample containing 97% ee is a colourless viscous oil (C, Figure 4). The products

may be hydrolysed to furnish the corresponding N-aryl--amino acids or amides.24

Colourless gum-like solid, mp 89.5–91 °C, [α]D = –3.3 (c 3.62, CHCl3, 93% ee) or colourless viscous

oil, [α]D –4.9 (c 3.69, CHCl3, 97% ee). Chiral HPLC (Chiralpak AD-H column, 1.0 mL/min,

hexane:IPA 95:5 v/v, 254 nm) tR (major) = 25.0 min, tR (minor) = 29.8 min (Figure 3). 1H NMR (400

MHz, CDCl3) δ 7.86 (br s, 1H), 7.21–7.14 (m, 2H), 6.72 (m, 1H), 6.64 (m, 2H), 4.03 (m, 1H), 3.76 (s,

3H), 3.76 (s, 1H), 3.05 (dd, 1H, J = 15.9, 6.0 Hz), 2.89 (dd, 1H, J = 15.9, 6.0 Hz), 1.30 (d, 3H, J = 6.3

Hz). 13C-{1H} NMR (100 MHz, CDCl3) δ 172.6, 152.2, 146.7, 129.3, 118.0, 113.9, 53.0, 46.0, 42.2,

20.8.

Figure 3. Chiral HPLC chromatograms of (3-phenylaminobutyryl)carbamic acid methyl ester: (a)

racemic sample; (b) prepared by protocol A; (c) prepared by protocol B.

Figure 4. Visual appearances of the aza-Michael adduct: A = racemic sample; B = 93% ee; C = 97%

ee.

__________________________________________________________________________________

EXPERIMENTAL DESIGN

Figure 5. Reaction Scheme.

Due to the highly corrosive nature of nitric acid and trifluoromethanesulfonic acid, added precaution

is necessary to avoid direct contact with these reagents during the preparation of Pd(OTf) 2∙2H2O. The

triflate salt is isolated as a hygroscopic, light purple/lilac powder, which will degrade within minutes

into a dark brown liquid if left exposed to moist air. Pd(OTf)2∙2H2O has been prepared successfully

several times in our laboratory on 1-10 g scale. When not used immediately, it can be kept in a sealed

tube over P2O5 in a desiccator for up to a year without any visible degradation.

Use of acetonitrile as a coordinating solvent helps to stabilise the product and avoid the formation of

the 1:2 adduct, [Pd(R-BINAP)2][OTf]2, which is observed as a side-product when the reaction is

performed in CH2Cl2.26 During the preparation of the diphosphine complexes, exposure of

Pd(OTf)2∙2H2O to acetonitrile in the absence of ligands should be kept to a minimum to avoid

polymerisation of the solvent. Once prepared, the diphosphine palladium complexes can be stored at

room temperature in a sealed vial, although exposure to light should be minimised. Samples prepared

>5 years ago in our laboratory has retained their original effectiveness.

The procedure has been repeated numerous times by several researchers of varying abilities

(undergraduate, postgraduate and postdoctoral researchers) in over 7 years in our laboratory, during

which the chemical precursors have been procured from different sources. This did not cause

noticeable differences in the results.

MATERIALS

CAUTION: All synthetic operations must be carried out in a fume cupboard. Personal protective

clothing (nitrile gloves, laboratory coat and safety glasses) must be donned at all times.

• Palladium(II) nitrate hydrate (CAS Number 11102-05-3) <CAUTION> Oxidizer, irritant

• Trifluoromethanesulfonic acid (CAS Number 1493-13-6) <CAUTION> Highly corrosive, toxic

• (R)-(+)-(1,1′-Binaphthalene-2,2′-diyl)bis(diphenylphosphine) (CAS Number 76189-55-4)

• Potassium carbonate <CAUTION> Toxic, irritant

• Sodium hydroxide <CAUTION> Toxic, irritant

• Magnesium sulfate (anhydrous)

• Acetonitrile extra dry (CAS Number 75-05-8) <CAUTION> Flammable, toxic, irritant

• Diethyl ether (anhydrous) <CAUTION> Highly flammable, toxic

• Dichloromethane (anhydrous) <CAUTION> Suspected carcinogenity

• Celite® 512 Medium (CAS Number 91053-39-3) <CAUTION> Irritant

EQUIPMENT

•

5-digit analytical balance

•

Thermally controlled magnetic stirring plate

•

Dreschel bottle (250 mL)

•

Schlenk tubes (50 mL, 100 mL)

•

Tubing adapter with side arm (cone size19/26, socket size 19/26)

•

Rubber septa (joint: ST/NS 14/20, 19/22, 24/40)

•

PVC tubing (8 mm bore, 10 mm O.D.)

•

Teflon-coated stirring bars

•

Disposable syringes (5 mL, 10 mL, 20 mL)

•

Stainless steel needle (170 mm in length, size 21 gauge)

•

Pasteur pipettes

•

Pyrex centrifuge tubes (20 mL)

•

Erlenmeyer flasks (100 mL, 500 mL)

•

Centrifuge machine

•

Glass vacuum oven for sample drying

•

High-vacuum pump

•

Disposable needles (120 mm, 50 mm)

•

Funnels (diameter 55 mm, 80 mm)

•

Pump (max pressure 100 mmHg)

•

Heavy wall flat bottomed filter flasks (500 mL)

•

Filtration funnel (diameter 4.5 mm, porosity 2)

•

Melting point apparatus

•

Polarimeter

REAGENT SETUP

• Anhydrous solvents (dichloromethane and diethyl ether) were obtained using a solvent purification

apparatus, by passing them through columns of activated molecular sieves under N2.

• Preparation of 0.07 M aq. NaOH: the title solution was prepared by dissolving NaOH pellets (0.28 g,

7.00 mmol) in distilled water (100 mL).

EQUIPMENT SETUP

Figure 6. Equipment setup for the preparation of Pd(OTf)2∙2H2O (steps 1-4).

•

Preparation of palladium triflate (Figure 6): the Schlenk tube and stirring bar were oven-dried

at 100 °C overnight. The Schlenk tube is attached to a N2/vacuum double manifold via a side arm

adapter, placed on top of the Schlenk tube (labeled A). The top of the adapter was then sealed with a

rubber septum (closing the tap on the side of the Schlenk tube then gives a sealed vessel which can be

purged). The hose connector on the side of the Schlenk tube (labeled B) was connected via plastic

tubing to a Dreschel bottle containing a sat. aq. K2CO3 solution (labeled C). This acts as an acid

scrubber for the waste stream.

•

The glass vacuum oven for drying was set up at 120 °C.

•

The centrifuge was set up at 1500 g.

Procedure

Steps 1-7: Synthesis of palladium(II) bis(trifluoromethansulfonate) dihydrate, Pd(OTf)2.2H2O, 1

1 Weigh out Pd(NO3)2.nH2O (1.00 g, 4.34 mmol, anhydrous basis) and place it in a Schlenk tube

equipped with a stirring bar. Seal with a rubber septum. Close the tap (B) on the side arm of the

Schlenk tube.

2 Attach the flask to a Schlenk line via the tubing adapter (A), and evacuate the flask by the

application of vacuum for 10 min with magnetic stirring, then fill it with nitrogen gas under a slightly

positive pressure.

3 The tap on the Schlenk tube’s side-arm (B) is then released, such that a steady stream of nitrogen

flows from the flask into the Dreschel bottle containing a solution of sat. aq. K2CO3 (acid scrubber).

Flow rate ca. 3 bubbles/sec.

4 With the magnetic stir bar set to rotate at 400 rpm, add triflic acid (7.30 mL, 83.00 mmol) dropwise

to the flask using a disposable plastic syringe. Fuming (nitric acid vapour) should be immediate

visible (Figure 7) Maintain a rate of addition such as to allow for a slow but steady quench of the acid

vapour by the acid scrubber. After complete addition, allow the resultant mixture to stir at room

temperature for a further 2 h.

<CAUTION> Maintain a steady flow of nitrogen through the apparatus throughout the procedure to

purge the nitric acid fumes, and to ensure that K2CO3 solution cannot be drawn back into the reaction

vessel, risking violent reaction with triflic acid.

5 Using a wide pipette, transfer the lilac slurry in roughly equal quantities to two centrifuge tubes

(Figure 7), seal them with rubber septa and centrifuge at 1500 g for 5 min.

6 Remove the supernatant using a pipette, and place the tubes in a small vacuum oven to dry at 120

°C and 0.03 mmHg for 18 h.

<CRITICAL STEP> Whist slurried in triflic acid, palladium (II) triflate is stable enough to be handled

briefly in air.

7 Flush the drying piston with dry nitrogen before retrieving the tubes, which are immediately sealed

with a rubber septum.

<PAUSE POINT> Palladium triflate dihydrate is a pale-lilac powder. It is highly moisture sensitive

and must be handled avoiding contact with air and stored in a desiccator over P2O5. Other less

powerful desiccants are less effective.

Figure 7. (a) Step 4: the addition of triflic acid; (b) Step 5: transfer of the suspension containing the

lilac product.

Steps 8-14: Synthesis of [(R-BINAP)Pd(OH2)2][OTf]2, 2

8 Equip a Schlenk tube with a stirring bar and a rubber septum, then purge with nitrogen via the sidearm. Close the tap and remove the nitrogen line, record the tare weight of the flask.

9 Under an inverted funnel attached to a nitrogen line, add Pd(OTf)2∙2H2O (1) (2.44 g, 5.54 mmol) to

the flask.

<CRITICAL STEP> In order to reduce exposure to air, the palladium salt should be added in a single

portion. Seal the flask immediately and weigh it again to ascertain the exact quantity.

10 Re-attach the nitrogen line to the side-arm and add dry acetonitrile (50 mL). The formation of an

orange solution is observed. The solution will look brown/black in the presence of colloidal

palladium.

11 Remove the rubber septum and add (R)-BINAP (3.45 g, 5.54 mmol) to the solution as a single

portion (Figure 8). Reseal the tube and stir the reaction mixture at room temperature for 30 min. If a

clear, yellow solution is obtained, step 12 can be skipped.

12 Using a Buchner funnel, filter the solution through a short plug of Celite (~2 cm) and rinse with 10

mL of acetonitrile (Figure 8).

13 Dilute the filtrate (yellow solution) with diethyl ether (300 mL). Leave the resulting solution for 30

min at room temperature to let the product precipitate (Figure 9). Collect the precipitated product

using a frit, rubber ring and filtration funnel.

14 Allow the solid to dry under vacuum.

<PAUSE POINT> The desired product is a stable yellow crystalline solid, which can be stored

indefinitely at room temperature in a closed vial, purged with nitrogen.

Figure 8. (a) Step 11: Addition of (R)-BINAP to the solution of Pd(OTf)2.2H2O. (b) Step 12:

Filtration of reaction mixture through Celite.

Figure 9. Step 13: Precipitation of complex 2.

Steps 15-19: Synthesis of [(R-BINAP)Pd(µ-OH)]2[OTf]2, 3

15 Weigh [(R-BINAP)Pd(OH2)2][OTf]2 (1.30 g, 1.22 mmol) into a 100 mL Erlenmeyer flask

containing a magnetic stirrer. Dissolve it in dichloromethane (20 mL) to form a yellow solution.

16 Using a 20 mL syringe, add aq. NaOH (0.07 M, 17.5 mL) in one portion (Figure 10, left). To stop

the solvent from evaporating, seal the top of the reaction flask with an inverted septum, with an

escape needle (Figure 10, middle). Stir the reaction mixture vigorously for 2 h, whereupon the

solution turns a deep burgundy colour (Figure 10, right).

17 Separate the biphasic mixture in a separatory funnel; wash the organic layer with water (3×15 mL),

dry it over anhydrous MgSO4.

18 Separate the solution from the desiccant by filtration, and concentrate the filtrate using a rotary

evaporator.

19 Recrystallize the crude product from dichloromethane/diethyl ether mixture (1.5 mL/5.0 mL),

collect the product by filtration

20 Dry the product under high vacuum.

<PAUSE POINT> The desired product is a stable red-orange powder and can be stored at room

temperature in a closed vial purged with nitrogen.

Figure 10. Step 16: Addition of aq. NaOH and colour change observed during the reaction.

Figure 11. Appearance of: (a) Palladium salt 1; and (b) complexes 2 (left) and 3 (right).

TIMING

• Synthesis of (1): Steps 1-3, 15 min; Step 4, 2 h 10 min; Step 5, 10 min; Steps 6-7, 18 h 15 min. Total

time: 20 h 50 min.

• Synthesis of (2): Step 8, 10 min; Step 9, 5 min; Step 10, 10 min; Steps 11, 35 min; Step 12, 15 min;

Step 13, 1 h; Step 14, 3 h. Total time: 5 h 15 min.

• Synthesis of (3): Step 15, 10 min; Step 16, 2 h 5 min; Steps 17-18, 1 h; Step 19, 30 min; Step 20, 3

h. Total time: 6 h 45 min.

ANTICIPATED RESULTS

In general, yields are usually very good for these reactions:

Palladium salt 1: 90–94 %; monomeric complex 2: 91–97%; dimeric complex 3: 90–97%.

TROUBLESHOOTING

Step

Problem

Solution

7

Pd(OTf)2∙2H2O (1) appears brown

The colour change is due to exposure to

moist air. In some cases, it may still be

used for the preparation of 2, albeit in a

lower yield.

14

Poor recovery of complex 2

The mother liquor (filtrate) obtained in

step 13 can be evaporated using the

rotavap, and further crops of crystals

obtained by recyrstallisation from

acetonitrile/ether or

dichloromethane/ether.

14

Impurity present in diphosphine

Purified by recrystallisation (above), or

complex 2

start the synthesis again with a fresh

sample of 1.

16

Colour change not observed

The colour change may not be observed

if more dilute solutions of NaOH is used

(< 0.007 M). In this case, the reaction

progress can be monitored by diluting

aliquots of the organic layer with

CDCl3and analysed by 31P NMR

spectroscopy.

ANALYTICAL DATA

Palladium triflate dihydrate (1): yield 94 %, pale-lilac powder, mp > 300 °C.

[(R)-(+)-2,2′-bis(diphenylphosphino)-1,1′-binaphthyl]-diaquo-palladium(II)

bis(trifluoromethanesulfonate) (2): yield 97 %, yellow crystals, mp 182.0–184.0 °C, [α]20D = +367.2 (c 1.22,

CH2Cl2).

1

H NMR (400 MHz, CDCl3) δ 7.86–7.84 (m, 6H), 7.70–7.63 (m, 12H), 7.56–7.50 (4H, m), 7.22 (t, 2H, J = 6.6

Hz), 7.06–7.02 (m, 3H), 6.90 (br s, 3H), 6.73 (d, 2H, J = 8.6 Hz), 4.00–3.75 (br s, 4H), 1.91 (s, 3H).

13

C-{1H} NMR (100 MHz, CDCl3) δ 139.6, 135.0, 134.9, 134.8, 134.5, 133.0, 132.9, 132.0, 130.4, 130.3,

129.4, 129.3, 129.1, 128.7, 128.5, 127.7, 127.6, 127.0, 124.5, 123.9, 123.0, 122.4, 122.0, 121.0, 118.9, 118.8,

118.3, 2.3

31

P -{1H} NMR (162 MHz, CDCl3) δ +33.0 (s)

[bis{((R)-(+)-2,2′-bis(diphenylphosphino)-1,1′-binaphthyl)palladium(II)}bis(μ−hydroxo)]

bis(trifluoromethanesulfonate) (3): yield 97 %, red-orange powder, mp 223.0–224.0 °C, [α]20D =+652.2 (c

1.15, CH2Cl2).

1

H NMR (400 MHz, CDCl3) δ 7.73–7.70 (m, 6H), 7.66–7.64 (m, 6H), 7.55–7.47 (m, 16H), 7.44–7.40 (m, 6H),

7.23–7.21 (t, 10H, J = 7.0 Hz), 7.11–7.03 (m, 16H), 6.59 (d, 4H, J = 8.6 Hz), -2.85 (s, 2H).

13

C-{1H} NMR (100 MHz, CDCl3) δ 138.6, 138.6, 138.5, 134.7, 134.4, 132.9, 131.7, 131.6, 130.1, 128.9,

128.9, 128.8, 128.5, 128.2, 127.0, 126.9, 124.8, 124.1, 123.4, 123.0, 122.8, 120.4, 119.9, 119.8

31

P-{1H} NMR (162 MHz, CDCl3) δ +29.1 (s)

AFFILIATION

Department of Chemistry, Imperial College London, U.K.

ACKNOWLEDGMENTS

AES is supported by a Marie Curie Intra European Fellowship, within the 7th European Community

Framework Programme (Project 252247).

CONTRIBUTIONS

AMRS refined the original procedures for catalyst preparation, AES carried out the experimental

procedure and aza-Michael reactions, and KKH assembled the manuscript.

COMPETING FINANCIAL INTERESTS

The authors declare no competing financial interests.

CORRESPONDING AUTHOR

Correspondence to: K. K. (Mimi) Hii, Department of Chemistry, Imperial College London, South

Kensington, London SW7 2AZ, U.K.

REFERENCES

1

Hamashima, Y., Hotta, D. & Sodeoka, M. Direct generation of nucleophilic chiral palladium

enolate from 1,3-dicarbonyl compounds: Catalytic enantioselective Michael reaction with

enones. J. Am. Chem. Soc. 124, 11240-11241 (2002), doi:10.1021/ja027075i.

2

Hamashima, Y., Hotta, D., Umebayashi, N., Tsuchiya, Y., Suzuki, T. & Sodeoka, M.

Catalytic enantioselective Michael reaction of 1,3-dicarbonyl compounds via formation of

chiral palladium enolate. Adv. Synth. Catal. 347, 1576-1586 (2005),

doi:10.1002/adsc.200505199.

3

Hamashima, Y., Sasamoto, N., Hotta, D., Somei, H., Umebayashi, N. & Sodeoka, M.

Catalytic asymmetric addition of beta-ketoesters to various Imines by using chiral palladium

complexes. Angew. Chem. Int. Ed. 44, 1525-1529 (2005), doi:10.1002/anie.200462202.

4

Sasamoto, N., Dubs, C., Hamashima, Y. & Sodeoka, M. Pd(II)-catalyzed asymmetric addition

of malonates to dihydroisoquinolines. J. Am. Chem. Soc. 128, 14010-14011 (2006),

doi:10.1021/ja065646r.

5

Fukuchi, I., Hamashima, Y. & Sodeoka, M. Catalytic asymmetric aldol reactions of

enolizable carbon pronucleophiles with formaldehyde and ethyl glyoxylate. Adv. Synth. Catal.

349, 509-512 (2007), doi:10.1002/adsc.200600568.

6

Umebayashi, N., Hamashima, Y., Hashizume, D. & Sodeoka, M. Catalytic enantioselective

aldol-type reaction of beta-ketosters with acetals. Angew. Chem. Int. Ed. 47, 4196-4199

(2008), doi:10.1002/anie.200705344.

7

Hamashima, Y., Sasamoto, N., Umebayashi, N. & Sodeoka, M. Pd-II-catalyzed asymmetric

addition reactions of 1,3-dicarbonyl compounds: Mannich-type reactions with N-Boc Imines

and three-component aminomethylation. Chemistry--Asian J. 3, 1443-1455 (2008),

doi:10.1002/asia.200800120.

8

Sodeoka, M. & Hamashima, Y. Chiral Pd aqua complex-catalyzed asymmetric C-C bondforming reactions: a Brønsted acid-base cooperative system. Chem. Commun. 5787-5798

(2009), doi:10.1039/b911015a.

9

Sodeoka, M., Tokunoh, R., Miyazaki, F., Hagiwara, E. & Shibasaki, M. Stable diaqua

palladium(II) complexes of BINAP and Tol-BINAP as highly efficient catalysts for

asymmetric aldol reactions. Synlett, 463 (1997).

10

Hagiwara, E., Fujii, A. & Sodeoka, M. Enantioselective addition of enol silyl ethers to imines

catalyzed by palladium complexes: A novel way to optically active acylalanine derivatives. J.

Am. Chem. Soc. 120, 2474-2475 (1998), doi:10.1021/ja973962n.

11

Fujii, A., Hagiwara, E. & Sodeoka, M. Mechanism of palladium complex-catalyzed

enantioselective Mannich-type reaction: Characterization of a novel binuclear palladium

enolate complex. J. Am. Chem. Soc.121, 5450-5458 (1999), doi:10.1021/ja9902827.

12

Fujii, A., Hagiwara, E. & Sodeoka, M. Asymmetric Mannich-type reaction catalyzed by

palladium complexes. J. Synth. Org. Chem. Jpn 58, 728-735 (2000).

13

Kang, Y. K. & Kim, D. Y. Catalytic enantioselective electrophilic α-amination of β-ketoesters

catalyzed by chiral palladium complexes. Tetrahedron Lett. 47, 4565-4568 (2006),

doi:10.1016/j.tetlet.2006.05.003.

14

Hamashima, Y., Yagi, K., Takano, H., Tamas, L. & Sodeoka, M. An efficient

enantioselective fluorination of various beta-ketoesters catalyzed chiral palladium complexes.

J. Am. Chem. Soc. 124, 14530-14531 (2002), doi:10.1021/ja028464f.

15

Hamashima, Y., Suzuki, T., Takano, H., Shimura, Y. & Sodeoka, M. Catalytic

enantioselective fluorination of oxindoles. J. Am. Chem. Soc. 127, 10164-10165 (2005),

doi:10.1021/ja0513077.

16

Hamashima, Y., Suzuki, T., Shimura, Y., Shimizu, T., Umebayashi, N., Tamura, T.,

Sasamoto, N. & Sodeoka, M. An efficient catalytic enantioselective fluorination of betaketophosphonates using chiral palladium complexes. Tetrahedron Lett. 46, 1447-1450 (2005),

doi:10.1016/j.tetlet.2005.01.018.

17

Hamashima, Y., Suzuki, T., Takano, H., Shimura, Y., Tsuchiya, Y., Moriya, K.-i., Goto, T. &

Sodeoka, M. Highly enantioselective fluorination reactions of beta-ketoesters and betaketophosphonates catalyzed by chiral palladium complexes. Tetrahedron 62, 7168-7179

(2006), doi:10.1016/j.tet.2005.12.070.

18

Hamashima, Y. & Sodeoka, M. Enantioselective fluorination reactions catalyzed by chiral

palladium complexes. Synlett, 1467-1478 (2006), doi:10.1055/s-2006-941578.

19

Moriya, K.-i., Harnashima, Y. & Sodeoka, M. Pd(II)-catalyzed asymmetric fluorination of

alpha-aryl-alpha-cyanophosphonates with the aid of 2,6-lutidine. Synlett, 1139-1142 (2007),

doi:10.1055/s-2007-977437.

20

Suzuki, T., Goto, T., Hamashima, Y. & Sodeoka, M. Enantioselective fluorination of tertbutoxycarbonyl lactones and lactams catalyzed by chiral Pd(II)-bisphosphine complexes. J.

Org. Chem. 72, 246-250 (2007), doi:10.1021/jo062048m.

21

Smith, A. M. R., Billen, D. & Hii, K. K. Palladium-catalysed enantioselective alphahydroxylation of beta-ketoesters. Chem. Commun. 3925-3927 (2009), doi:10.1039/b907151b.

22

Smith, A. M. R., Rzepa, H. S., White, A. J. P., Billen, D. & Hii, K. K. Delineating Origins of

Stereocontrol in Asymmetric Pd-Catalyzed alpha-Hydroxylation of 1,3-Ketoesters. J. Org.

Chem. 75, 3085-3096 (2010), doi:10.1021/jo1002906.

23

Li, K. L. & Hii, K. K. Dicationic [(BINAP)Pd(solvent)2][TfO]2: enantioselective

hydroamination catalyst for alkenoyl-N-oxazolidinones. Chem. Commun., 1132-1133 (2003),

doi:10.1039/b302246c.

24

Li, K. L., Cheng, X. H. & Hii, K. K. Asymmetric synthesis of beta-amino acid and amide

derivatives by catalytic conjugate addition of aromatic amines to N-alkenoylcarbamates. Eur.

J. Org. Chem., 959-964 (2004), doi:10.1002/ejoc.200300740.

25

Hamashima, Y., Somei, H., Shimura, Y., Tamura, T. & Sodeoka, M. Amine-salt-controlled,

catalytic asymmetric conjugate addition of various amines and asymmetric protonation. Org.

Lett. 6, 1861-1864 (2004), doi:10.1021/ol0493711.

26

Phua, P. H., White, A. J. P., de Vries, J. G. & Hii, K. K. Enabling ligand screening for

palladium-catalysed enantioselective aza-Michael addition reactions. Adv. Synth. Catal. 348,

587-592 (2006), doi:10.1002/adsc.200505404.

27

Phua, P. H., Mathew, S. P., White, A. J. P., de Vries, J. G., Blackmond, D. G. & Hii, K. K.

Elucidating the mechanism of the asymmetric aza-Michael reaction. Chemistry—Eur. J. 13,

4602-4613 (2007), doi:10.1002/chem.200601706.

28

Hamashima, Y., Tamura, T., Suzuki, S. & Sodeoka, M. Enantioselective protonation in the

aza-Michael reaction using a combination of chiral Pd-mu-hydroxo complex with an amine

salt. Synlett 1631-1634 (2009), doi:10.1055/s-0029-1217347.

29

Hamashima, Y., Suzuki, S., Tamura, T., Somei, H. & Sodeoka, M. Scope and mechanism of

tandem aza-Michael reaction/enantioselective protonation using a Pd-mu-hydroxo complex

under mild conditions buffered with amine salts. Chemistry--Asian J. 6, 658-668 (2011),

doi:10.1002/asia.201000740.

30

Li, K. L., Horton, P. N., Hursthouse, M. B. & Hii, K. K. Air- and moisture-stable cationic

(diphosphine)palladium(II) complexes as hydroamination catalysts X-ray crystal structures of

two [(diphosphine)Pd(NCMe)(OH2)][OTf]2 complexes. J. Organomet. Chem. 665, 250-257

(2003), doi:10.1016/s0022-328x(02)02138-1.

31

Kawatsura, M. & Hartwig, J. F. Palladium-catalyzed intermolecular hydroamination of

vinylarenes using arylamines. J. Am. Chem. Soc. 122, 9546-9547, doi:10.1021/ja002284t

(2000).

32

Kang, Y. K., Kwon, B. K., Mang, J. Y. & Kim, D. Y. Chiral Pd-catalyzed enantioselective

Friedel-Crafts reaction of indoles with gamma,delta-unsaturated beta-keto phosphonates.

Tetrahedron Letters 52, 3247-3249 (2011), doi:10.1016/j.tetlet.2011.04.084.

33

Aikawa, K., Hioki, Y. t., Shimizu, N. & Mikami, K. Catalytic asymmetric synthesis of stable

oxetenes via Lewis acid-promoted [2 + 2] cycloaddition. J. Am. Chem. Soc. 133, 2009220095 (2011), doi:10.1021/ja2085299.

34

Pignat, K., Vallotto, J., Pinna, F. & Strukul, G. Cationic complexes of palladium(II) and

platinum(II) as Lewis acid catalysts for the Diels−Alder reaction. Organometallics 19, 51605167 (2000), doi:10.1021/om0003943.

35

Murata, S. & Ido, Y. Practical synthesis of palladium bis(trifluoromethanesulfonate) and its

application to the synthesis of palladium complexes. Bull. Chem. Soc. Jpn. 67, 1746-1748

(1994), doi:10.1246/bcsj.67.1746

36

Phua, P. H., de Vries, J. G. & Hii, K. K. Palladium-catalysed enantioselective conjugate

addition of aromatic amines to alpha,beta-unsaturated N-imides. Effect of the chelating

moiety. Adv. Synth. Catal. 347, 1775-1780 (2005), doi:10.1002/adsc.200505126.

37

Guino, M., Phua, P. H., Caille, J. C. & Hii, K. K. A concise asymmetric synthesis of

torcetrapib. J. Org. Chem. 72, 6290-6293 (2007), doi:10.1021/jo071031g.