2009-2010 Greenhouse Gas Emissions Report Capital Planning

advertisement

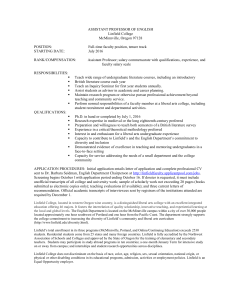

2009-2010 Greenhouse Gas Emissions Report Capital Planning & Development Department Sustainability Interns Fall 2010 / Spring 2011 Completed December 15, 2011 Linfield College Green House Gas Report January 2012 ABSTRACT Using data gathered from fiscal year 2009-2010, this report is the second inventory of Linfield’s McMinnville Campus greenhouse gas emissions, in accordance with the American College and University President’s Climate Commitment. It forms a basis for future biannual emissions reports, and towards development of an action plan to reduce greenhouse gas emissions. Significant finds of this report compared with the first inventory: 2006-2007 2009-2010 Emission Total Scope 1 Scope 2 Scope 3 Totals MT eC02 3,368 NA 4,511 7,879 MT eC02 3,380 NA 4,523 7,903 Emissions per Linfield student Emissions per 100 square feet Emissions per $10.000 of 4.6 MT eC02 8.0 MT eC02 2.0 MT eCO2 4.9 MT eC02 8.0 MT eC02 2.1 MT eCO2 Underlined years 2007 & 2010 will refer to the respective fiscal year throughout this report The data for 2010 year has increased 1.0% from our first report. This increase is attributed to additional emission categories not included in the first report. Linfield now includes refrigerants & chemicals, agriculture, solid waste and waste water into our data base, and deleted faculty/staff/student commuting mileage due to lack of verification. These changes along with original interpretation of data created comparative differences between the first and second reports. Linfield will use the 2010 year as the new benchmark year for comparison with future changes in our green house gas emissions. Because Linfield’s electricity is sourced from 96% hydroelectric and 4% wind power and other sources there are no emissions reported for electrical usage. Nonetheless, it remains important to reduce electricity usage due to capacity constraints on carbon neutral electricity sources. Use of hydroelectric and wind power instead of regional average electricity sources allows Linfield to avoid emissions of 3,713 MT eC02, which corresponds to 2.3 MTeC02 per student, a savings of 32%. INTRODUCTION In the fall of 2007, Linfield College President Thomas L. Hellie appointed an Advisory Committee on the Environmental and Sustainability (ACES), comprised of students, faculty and staff. That committee compiled information about what Linfield has been doing to reduce greenhouse gas emissions and recommended that the President sign the American College and University Presidents Climate Commitment (ACUPCC) to reduce those emissions. On April 22, 2008, Earth Day, President Hellie signed that commitment. Since the signing of the ACUPCC document Linfield has completed several energy conservations projects saving approximately 1 million kWh (1). This would be in addition to energy savings from past projects. METHODS Data was collected for Scopes 1, 2 and 3 following Clean Air-Cool Planet Campus Calculator (CACP) and all conclusions reported were based on results from that calculator. The ACUPCC identifies direct and indirect emissions which are divided into three scopes used for reporting purposes. Definitions below are quoted from ACUPCC Implementation Guide. Scope 1 includes “direct GHG emissions occurring from sources that are owned or controlled by the institution including: on-campus stationary combustion of fossil fuels; mobile combustion of fossil fuels by institution owned/controlled vehicles; and fugitive emissions”. Linfield owns and operates a Central Heating Plant (CHP) which produces steam from natural gas. The college is on interruptible tariff which requires Linfield to use heating fuel oil, diesel light or PS300 fuels as back-up in case of natural gas shortages. There was an interruption of natural gas during the 2010 fiscal year and heating fuel oil was included into the final calculation of emissions. Scope 1 emission sources for Linfield College include: the CHP, Direct Transportation, and two new sources: Refrigerants & Chemicals and Agriculture (fertilizers). These newest categories increased emissions by 82 MT eC02 or 2.4% from our 07 data. Data collected from Capital Planning & Development Office and Facilities Services Scope 2 includes “direct emissions generated in the production of electricity consumed by the institution”. Linfield purchases its electricity from McMinnville Water & Light who purchases 96% from Bonneville Power Administration as hydroelectric power. The remaining 4% is purchased from a variety of sources including wind (2). Therefore, campus electricity usage does not directly contribute to Linfield’s C02 emissions in a significant and tractable fashion. Although Linfield has no significant Scope 2 emissions, there is still a benefit to reducing electricity usage. Regional and national sources of carbon neutral electricity are limited, and by reducing Linfield’s electricity usage, capacity is made available to others. Hence, Linfield’s potential emissions, as if regional average sources of electricity were used, have also been calculated. This will allow Linfield to demonstrate the impact of future reductions in electrical usage. Utility data were provided by the Capital Planning & Development Office and information on electricity sources provided by McMinnville Water and Light. Scope 3 underscores “all other indirect emissions-those that are a consequence of the activities of the institution, but occur from sources not owned or controlled by the institution”. Data was collected from a variety of sources around campus including: Controller’s Office, Institutional Research, Human Resources, International Program Office, Facilities Services and Capital Planning. Emissions from solid and water waste was added to this category. These newly reported emissions increased Linfield’s total by 247 MT eC02 or 5.5% from 07 data. Information on solid waste CH4 Recovery for Electric Generation was provided by Western Oregon Waste and Waste Management. Information on the waste water treatment was provided by McMinnville Public Works Department. (3) Linfield did not include faculty/staff/student commuting emissions due to lack of accurate information. RESULTS AND ANALYSIS Linfield identified and collected new emission data on refrigerants, chemicals, fertilizer usage, solid waste and waste water in the 2010 year. These additions along with a reanalysis of the 2007 data suggested discrepancies in comparisons between the data sets of 2007 and 2010. Based on these changes the College has determined the 2010 year will become the new base line year. Emission Comparisons with other NW Colleges/Universities Linfield College’s emissions compare favorably with nearby liberal arts colleges as summarized in Table 1. Because Linfield’s electrical consumption is almost entirely from hydro our net emissions are considerably lower than similar colleges in the Pacific Northwest. If Linfield electrical consumption was included in our emissions calculations, then our total emissions would be 11,616 MTeC02 and emissions by FTE and GSF would be consistent with the other colleges. The electrical savings reduces emissions by 32%. Table 1. Emissions (MTeC02) Comparisons for all Scopes Net Total Emissions/FTE Emissions/1000GSF 2010 2010 2008 2007 Linfield Lewis & Clark Willamette University of Portland 7,903 4.9 8.0 12,554 3.6 10.0 17,934 6.9 12.8 17,772 5.5 14.9 Data collected from ACUPCC website Emission Distribution Figure 1 summarizes the distribution of emissions from different sources. 2009 Seattle Pacific____ 17,934 6.9 12.8 College related travel is the major contributor to Linfield’s green house gas emissions, followed by natural gas usage from our Central Heating Plant. Clearly if Linfield is to approach net zero emissions we will need to focus on these two items. In the future strategies will be developed to lower emissions in all categories with emphasis on the two largest. Lowering of natural gas emissions may be attainable and should be reviewed first. Table 2. Shows comparison between 2007 & 2010 natural gas usage Fiscal Year Therms MTeC02 Fall FTE Building GSF HDD* 2006-2007 565,853 2994 1713 981,007 5921 2009-2010 561,163 2985 1608 983,204 6656 Differences in consumption from 2007 and 2010 is only 0.8% is not considered significant. *HDD-Heating Degree Day (5) Addition of New Emissions to Baseline In calculating Linfield’s 2010 based year several additions to the 2007 data was included to Scopes 1 and 3. In Scope 1 refrigerants and fertilizers were added which increased total emissions by 82 MT eC02 or 2.4% from the 2007 data. In Scope 3 solid waste and waste water emissions were added which increased emissions by 247 MT eC02 or 5.4% from 2007 data. These increases were partially offset by decreases in existing categories. Table 2. Comparison of 2007 and 2010 emissions Scope 1 CHP Direct Transportation Refrigerants Fertilizers Totals Scope 2 MTeC02 2007 MTeCo2 2010 2994 374 N/A N/A 3368 2985 313 69 13 3380 N/A N/A Total Percent Change_______ 0.4% Scope 3 Commuting Air Travel Other Travel Solid Waste Water Waste Totals 1094 3319 98 N/A N/A 4511 N/A 4021 256 234 12 4523 0.3% Totals all Scopes 7879 7903 0.3% 100% of the emission increases are created by the additions of items in Scopes 1&3. CONCLUSIONS Comparison of 2007-2010 Emissions Data showed an increase of 24 MTeC02 from 2007 to 2010; however 328 MTeC02 is attributed to additional emission sources not previously identified. Additionally, no commuting emissions could be verified in 2010 and were omitted from totals. In 2007 commuting emissions accounted for 1094 MTeC02. During the periods between the two reports the college completed a variety of electrical energy conservation projects that reduced overall consumption by 902,715 kWh. This translates into lowering of our carbon footprint by 619 MT eC02 (6). Comparisons of Emissions with other NW Colleges and Universities Linfield’s net total emission are about half of the average emissions reported by 4 other Pacific NW colleges. This difference is attributed to the “Linfield Hydro Factor”, which allows Linfield to obtain most of its electrical energy from a renewable source. When factoring in the electrical energy consumed into our total emissions Linfield is still lower or equal to the comparison colleges in all emission categories. Emission Distribution Comparison of emission distribution is generally similar to our 2007 report with air travel and natural gas the largest contributors to emissions. Natural gas emissions were similar at 38% of the total MTeC02 produced for both years; while college travel was 58% for 2010 compared with 48% in 2007. We attribute the difference in how data was collected and calculated in 2007. Linfield’s travel abroad program is a prominent and important part of the curriculum which requires community discussion before strategies on emission reduction can be developed. Reductions in natural gas usage are attainable and can be developed through behavior and engineering changes. RECOMMENDATIONS 1. Immediately develop a procedure to capture all travel - miles by departments and establish as college policy. This is paramount in collecting consistent data between bi-annual periods. 2. Capital Planning & Development Office and Facilities Services work together in developing a natural gas reduction program. This program should comprise both engineered solutions along with a strong educational program to promote conservation. 3. Develop and conduct annual faculty/staff/student commuting surveys to provide a consistent methodology for calculating commuting emissions. 4. Use the 2010 GHG Report as the new baseline year. SOURCES OF INFORMATION (1). Linfield College internal document. Capital Planning & Development Office, July 21, 2010. Historic Record of Energy Conservation Projects. (2) Information provided by McMinnville Water & Light, December 2011. (3) Information obtained from Western Oregon Waste, November 2011 AND McMinnville Department of Public Works Environmental Services, September 2011 (4) MT eC02 numbers calculated using Linfield 2009-2010 CACP calculated results and extrapolating by ratio analysis (5) Heating Degree Days (HDD) is a calculation typically used to normalized energy data when calculating energy savings to buildings. (6) EPA-2011, eGRID 2010 Version 1.1 Formula: 6.8956 x10-4 MT C02 /kWh.