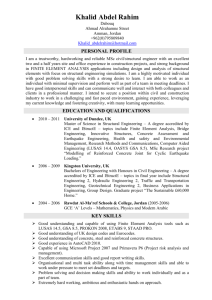

design & construction studies - Bohol Island State University Clarin

advertisement