POLA_26239_sm_SuppInfo

advertisement

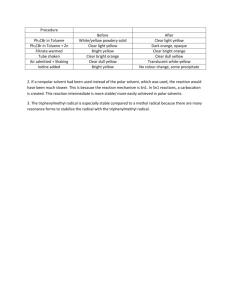

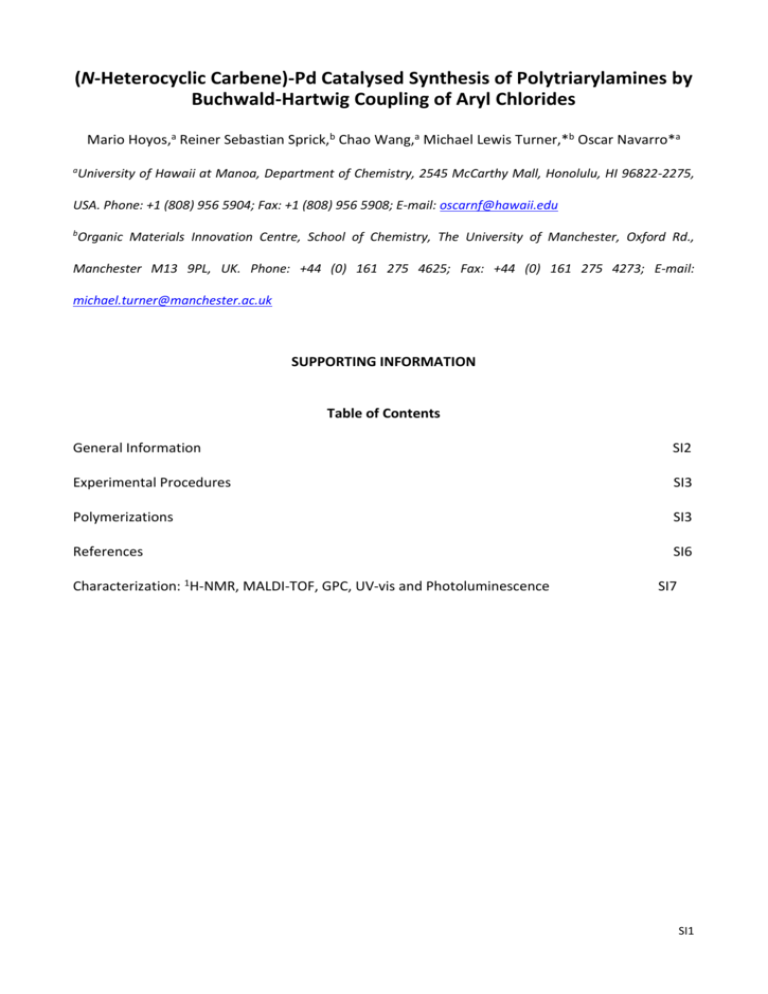

(N-Heterocyclic Carbene)-Pd Catalysed Synthesis of Polytriarylamines by Buchwald-Hartwig Coupling of Aryl Chlorides Mario Hoyos,a Reiner Sebastian Sprick,b Chao Wang,a Michael Lewis Turner,*b Oscar Navarro*a a University of Hawaii at Manoa, Department of Chemistry, 2545 McCarthy Mall, Honolulu, HI 96822-2275, USA. Phone: +1 (808) 956 5904; Fax: +1 (808) 956 5908; E-mail: oscarnf@hawaii.edu b Organic Materials Innovation Centre, School of Chemistry, The University of Manchester, Oxford Rd., Manchester M13 9PL, UK. Phone: +44 (0) 161 275 4625; Fax: +44 (0) 161 275 4273; E-mail: michael.turner@manchester.ac.uk SUPPORTING INFORMATION Table of Contents General Information SI2 Experimental Procedures SI3 Polymerizations SI3 References SI6 Characterization: 1H-NMR, MALDI-TOF, GPC, UV-vis and Photoluminescence SI7 SI1 GENERAL INFORMATION General Procedures. All manipulations were carried out under an inert nitrogen atmosphere, using ovendried glassware (125 °C). A N2-filled glovebox or standard Schlenk techniques were used as indicated. Rotary evaporation was done at 30 ºC. Column chromatography was performed on silica gel (Silicycle, 60 Å pore size, 40-63 mm particle size, pH suspension 10%: 7.4, volatile content (160 ºC): 3.0 %).1 Analytical thinlayer chromatography was performed on aluminum-baked flexible silica TLC plates (Whatman, 60 Å pore size and 250 m layer). Materials. Certified ACS grade toluene (95 %) was purchased from Fisher Scientific, and was degassed with N2 overnight, refluxed over Na, distilled under N2 atmosphere and stored over regenerated 3 Å molecular sieves2 before using for polymerizations. Anilines were purchased from Sigma-Aldrich and purified before using:3 2,4-dimethylaniline and 4-fluoroaniline were dried over NaOH overnight and then distilled under reduced pressure at 60 ºC and 100 mmHg. Imidazolium salts and well-defined NHC-Pd complexes were prepared according to procedures.4-9 Tris(dibenzylideneacetone) dipalladium(0) (99+%), Pd2(dba)3, tetrakis(triphenylphosphine(0) palladium (99.9+%-Pd), [Pd(PPh3)]4, and 1,3-Bis(2,6-di-ipropylphenyl)imidazol-2-ylidene(1,4-naphthoquinone) palladium-(0), [(IPr)Pd(NQ)]2 were purchased from Strem Chemicals, and tri-tert-butylphosphine (98 %) was purchased from Sigma-Aldrich. All these reagents were used without further purification. Sodium tert-butoxide was purchased from Sigma-Aldrich and sublimated before using. 4-Chlorobenzene boronic acid (97%), 1-chloro-4-iodobenzene (99%), 1bromooctane (99%), 2,7-dichlorofluorene (97%) were purchased from Fisher Scientific and used without further purification. Solvents for filtration and chromatography were certified ACS grade and were purchased from Fischer Scientific. Dry solvents were used from a Solvent Purification System MBraun-SPS. Instruments. 1H-NMR spectra were recorded on Varian Unity-300 MHz (75 MHz) spectrometer at 25ºC. Spectra are referenced to residual chloroform (d= 7.26 ppm, 1H). Chemical shifts are reported in ppm. Multiplicities are indicated by s (singlet), d (doublet), t (triplet), q (quartet), m (multiplet) and b (broad). Chemical shifts downfield of the standard are reported as positive values. The acquisition time was 1 s, the relaxation delay 4 s, the pulse angle 60º and at least 32 scans were accumulated. Polymer molecular weight was determined by GPC in tetrahydrofuran (THF), 99.5+% solution stabilized with 250ppm of BHT at room temperature (25 ºC), and at a flow rate of 1 mL/min using a Viscotex GPCmax VE2001 Varian equipped with one 5 cm, 10m guard column, one 30 cm, 10m PLgel 500 Å column and two 30 cm, 10m, PL mixed B columns and a Viscotex VE3580 RI detector. The system was calibrated with low polydispersity polystyrene standards in the range of 200 to 180×104 g/mol from Polymer Laboratories. Elution volumes were referenced to dodecane as a flow marker. Matrix-assisted laser desorption/ionisation time-of-flight (MALDI-TOF) mass spectrometry was carried out using a Shimazdu Biotech AXIMA Confidence MALDI mass spectrometer in linear (positive) mode, referencing against PPG 4K. 40 µL of PTAA solution (1 mg mL-1 in THF) was mixed with 20 µL of a 30 mg mL-1 solution of the matrix (dithranol) in THF. A drop of this mixed solution was then spotted onto a MALDI plate SI2 target which had been pre-spotted with a 10 mg mL-1 solution of NaI in THF. The MALDI plate was allowed to dry for 10 min at room temperature. UV-Vis absorption spectra were recorded on a Varian Cary 5000UV-Vis-NIR spectrophotometer and fluorescence spectra on a Varian Cary Eclipse fluorimeter. EXPERIMENTAL PROCEDURES Procedure for the synthesis of 4,4’-dichlorobiphenyl:10,11 Inside a glovebox, 1-chloro-4-iodobenzene (7.9 g, 33.1 mmol), 4-chlorophenylboronic acid (4.94 g, 31.6 mmol), [Pd(PPh3)]4 (0.69g, 0.6 mmol), NaOtBu (9.11g, 0.094 mol) and toluene (200 mL) were added into an oven-dried 500 mL Schlenk flask, containing a magnetic stir bar. The flask was capped with a glass stopper, removed from the glovebox and placed in an oil bath at 85 ºC for 24 h. When GC analysis showed total conversion of the boronic acid, the toluene was removed under reduced pressure. The product was purified by flash chromatography (silica gel, petroleum ether) to give 4,4’-dichlorobiphenyl as a crystalline white solid (6.41 g, 91 %). Rf = 0.9 (petroleum ether, UV). 1 H-NMR (300 MHz, CDCl3, δ): 7.48 (d, 4H, ArH), 7.40 (d, 4H, ArH). Procedure for the synthesis of 2,7-dichloro-9,9-dioctyl-9H-fluorene:12-14 2,7-Dichlorofluorene (2.5 g, 10.6 mmol), potassium hydroxide in powder form (2.8 g, 50 mmol) and potassium iodide (8.3 mg, 0.05 mmol) were added into an oven-dried 100 mL round flask containing a magnetic stir bar and adapted with an 10 mL addition funnel. The funnel was sealed with a rubber septum and the system was evacuated and refilled with nitrogen five times. DMSO (5 mL) was syringed in through the septum and the reaction was stirred for 1 h at 25 ºC. Octyl bromide (5.13 mL, 29.68 mmol) was then added dropwise to the reaction during 1 h. The mixture was kept 24 h with high stirring at 25 ºC. After GC analysis showed total conversion of the fluorene, the reaction mixture was poured in water (500 mL). The organic phase was extracted with toluene (3100 mL). The combined organic phase was dried over MgSO4 and removed by evaporation. Yellow colored oil was obtained which was further purified by column chromatography (silica gel, petroleum ether) to give a white solid (4.14g, 85 %). Rf = 0.8 (petroleum ether, UV). 1H-NMR (300 MHz, CDCl3, δ): 7.60 (d, 2H, ArH), 7.56 (d, 2H, ArH), 7.31 (m, 1H, ArH), 7.28 (m, 1H, ArH), 1.90 (t, 4H, -CH2-CH2-Ar), 1.3-0.9 (m, 20H, -CH2-), 0.8 (m, 4H, -CH2-CH2-CH2-Ar), 0.56 (t, 6H, -CH2-CH3). POLYMERIZATIONS Method A. General Procedure for polymerization: Inside the glovebox, the corresponding aryl chloride, base, (NHC)-Pd complex and solvent were added into an oven-dried 25 mL Schlenk flask containing a magnetic stir bar, and capped with a rubber septum. Outside the glovebox, fresh distilled aniline was syringed in through the septum. The reaction mixture was heated at 100 ºC for 16 h. After this time, 4chloroanisole was injected as the end-capper agent, and the reaction mixture was heated at 100 ºC up to 24 h. SI3 Method B. General Procedure for polymerization in presence of a end-capper agent: Inside the glovebox, the corresponding aryl chloride, base, (NHC)-Pd complex, solvent and the corresponding amount of 4chloroanisole (from a 0.1M toluene stock solution) were added into an oven-dried 25 mL Schlenk flask containing a magnetic stir bar. The flask was capped with a rubber septum and, outside the glovebox, fresh distilled aniline was injected through the septum. The reaction mixture was heated at 100 ºC for 24 h. Purification Method: The reaction was cooled to room temperature and polymers were precipitated into cold methanol, loaded onto a pad of silica and eluted by washing with dichloromethane. The solution was extracted with an aqueous sodium N,N-diethyldithiocarbamate solution (1M) in order to remove the possible traces of Pd,15 then water and dried over MgSO4. After evaporation of the solvent, polymers were precipitated from a concentrated solution of methylene chloride into methanol and filtered off. Polymers were purified by three Soxhlet extractions cycles under nitrogen with methanol, 2-butanone and recovered from dichloromethane. Final polymers were precipitated into methanol, filtered, and dried under vacuum at room temperature overnight. Figure S-1. Structures of the (NHC)-Pd complexes used in this work. SI4 Table S-1. Optimization of the catalytic system. For P1: 0.75 mmol ArNH2, 0.75 mmol 4,4’- dichlorobiphenyl, 0.75mmol/mL, toluene, 3 eq. NaOtBu, 4 mol% catalyst loading, 24 h, 100 ºC. a Unpurified products containing traces of base, palladium, ligands and unreacted termination groups. Entry NHC-Pd complex Yielda Mn Mw PDI 1 (IPr)Pd(allyl)Cl 99% 4,785 14,230 3.0 2 (SIPr)Pd(allyl)Cl 80% 2,000 3,120 1.6 3 (IMes)Pd(allyl)Cl 80% 2,655 4,195 1.6 4 (SIMes)Pd(allyl)Cl 17% 1,110 1,990 1.8 5 (IPr)Pd(cinnamyl)Cl 91% 4,500 13,470 3.0 6 (IPr)Pd(acac)Cl 90% 1,650 4,460 2.7 7 (IPr)Pd(AcO)2 18% 1,515 6,690 4.4 8 (IPr)PdPEPPSI 27% 1,570 2,980 1.9 9 [(IPr)Pd(naphtoquinone)]2 15% 1,720 7,380 4.3 Table S-2. Optimization of the catalytic system. For P1 and P2: 0.75 mmol ArNH2, 0.75 mmol 4,4’dichlorobiphenyl, 0.75mmol/mL, 4 mol% (IPr)Pd(allyl)Cl, 24 h, 100 ºC. For P3 and P4: 0.75 mmol ArNH2, 0.75 mmol 2,7-dichloro-9,9-dioctyl-9H-fluorene, 0.25mmol/mL, 4 mol% (IPr)Pd(allyl)Cl, 24 h, 100 ºC. a Unpurified products containing traces of base, palladium, ligands and unreacted termination groups. b Low solubility. c Reaction temperature: 125ºC. d Reaction temperature: 80ºC. Entry Polymer Base Solvent Yielda Mn Mw PDI 1 P1 NaOtBu (2 eq.) Toluene - - - - 2 P1 NaOtBu (2.2 eq.) Toluene 35% 1,705 2,425 1.4 3 P1 NaOtBu (3 eq.) Toluene 99% 4,785 14,230 3.0 4 P1 NaOtBu (4 eq.) Toluene 65% 4,085 8,930 2.2 5 P1 KOtBu (2 eq.) Toluene - - - - SI5 6 P1 KOtBu (2.2 eq.) Toluene 56% 2,600 5,460 2.1 7 P1 KOtBu (3 eq.) Toluene 90% 3,810 15,585 4.1 8b P1 KOtBu (4 eq.) Toluene - - - - 8 P1 NaOtBu (3 eq.) DME 65% 2,965 5,605 1.90 9 P1 NaOtBu (3 eq.) THF 32% 1,990 2,600 1.30 10 P1 NaOtBu (3 eq.) DMF 10% 2,560 3,330 1.30 12 P1 NaOtBu (3 eq.) Dioxane 31% 2,655 3,430 1.3 13c P1 NaOtBu (3 eq.) Toluene 98% 1,535 5,830 3.8 14d P1 NaOtBu (3 eq.) Toluene 79% 1,870 5,990 3.1 15 P2 NaOtBu (3 eq.) Toluene 98% 3,790 9,700 2.6 16 P3 NaOtBu (3 eq.) Toluene 97% 9,880 18,865 1.9 17 P4 NaOtBu (4 eq.) Toluene 97% 4,660 11,140 2.4 REFERENCES 1. Still, W. C.; Kahn, M.; Mitra, A. J. Org. Chem., 1978, 43, 2923-2925. 2. Joshi, S.; Fair, J. R. Ind. Eng. Chem. Res., 1988, 27(11), 2078-2085. 3. Armarego, W. L. F.; Chai, C. L. L. ‘Purification of Laboratory Chemicals’ 5th ed.; ButterworthHeinemann: Oxford, UK, 2003. 4. Arduengo, A. J.; Krafczyk, R.; Schmutzler, R.; Craig, H. A.; Goerlich, J. R.; Marshall, W. J.; Unverzagt, M. Tetrahedron, 1999, 55, 14523-14534. 5. Navarro, O.; Nolan, S. P. Synthesis, 2006, 2, 366-367. 6. Marion, N.; Navarro, O.; Mei, J.; Stevens, E. D.; Scott, N. M.; Nolan, S. P. J. Am. Chem. Soc. 2006, 128, 4101-4111. SI6 7. Navarro, O.; Kaur, H.; Mahjoor, P.; Nolan, S. P. J. Org. Chem., 2004, 69, 3173-3180. 8. Winkelmann, O.; Navarro, O. Adv. Synth. Catal. 2010, 352, 212-214. 9. Winkelmann, O.; Riekstins, A.; Nolan, S. P.; Navarro, O. Organometallics, 2009, 28, 5809-5813. 10. Lehmler, H.-J.; Robertson, L. W.; Chemosphere, 2001, 45, 137-143. 11. Yanagisawa, M.; Hayamizu, K.; Yamamoto, O. Mag. Res. 1987, 25, 184-186. 12. Nowacki, B.; Iamazaki, E.; Cirpan, A.; Karasz, F.; Atvars, T. D. Z.; Akcelrud, L. Polymer, 2009, 50, 6057-6064. 13. Zheng, M.; Ding, L.; Lin, Z.; Karasz, F. E. Macromolecules, 2002, 35, 9939-9946. 14. Ranger, M.; Rondeau, D.; Leclerc, M. Macromolecules, 1997, 30, 7686-7691. 15. Nielsen, K. T.; Bechgaard, K.; Krebs, C. Macromolecules 2005, 38, 658-659. CHARACTERIZATION: 1H NMR, MALDI-TOF, GPC, UV-Vis and Photoluminescence. Figure S-2. 1H-NMR spectrum of 4,4’-dichlorobiphenyl. SI7 Figure S-3. 1H-NMR spectrum of 2,7-dichloro-9,9-dioctyl-9H-fluorene. Figure S-4. 1H-NMR spectrum of uncapped poly[[(4-fluorophenyl)imino][1,1’-biphenyl]-4,4’-diyl] (P1). SI8 Figure S-5. 1H-NMR spectrum of uncapped poly[[(2,4-dimethylphenyl)imino][1,1’-biphenyl]-4,4’-diyl] (P2). Figure S-6. 1H-NMR spectrum of uncapped poly[[(4-fluorophenyl)imino]-9,9’-dioctylfluorene-2,7-diyl] (P3). SI9 Figure S-7. 1H-NMR spectrum of uncapped poly[[(2,4-dimethylphenyl)imino]-9,9’-dioctylfluorene-2,7-diyl] (P4). Figure S-8. 1H-NMR spectrum of end-capped poly[[(4-fluorophenyl)imino][1,1’-biphenyl]-4,4’-diyl] (P1). SI10 Figure S-9. MALDI-TOF spectrum of uncapped P1. Figure S-10. MALDI-TOF spectrum of uncapped P2. SI11 Figure S-11. MALDI-TOF spectrum of uncapped P3. Figure S-12. MALDI-TOF spectrum of uncapped P4. SI12 Figure S-13. UV-vis and PL spectra of polymers (─) P1, (●) P2, (─) P3 and (●) P4 in dichloromethane solution. The molar absorption coefficient is based on the repeat unit of the polymers. Figure S-14. Molecular weight distributions (GPC) of P1 synthesized using different catalyst loadings: (─) 1 mol%; (─) 2 mol%; (─) 4 mol%; (●) 8 mol%; (○) 16 mol%. SI13 Figure S-15. GPC traces of unpurified P1 (─) and P1after Soxhlet purification (─). Polymers correspond to entries 4 and 5 in Table 1, respectively. SI14