Novel Surface Peening Processing for Improved Fatigue Strength

advertisement

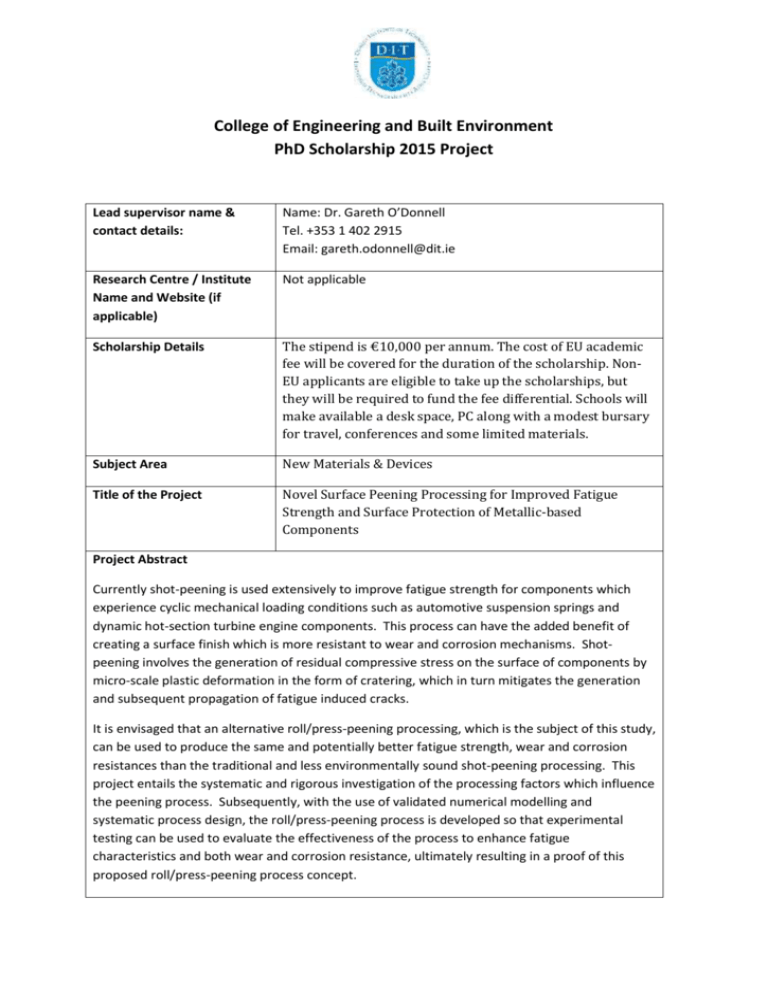

College of Engineering and Built Environment PhD Scholarship 2015 Project Lead supervisor name & contact details: Name: Dr. Gareth O’Donnell Tel. +353 1 402 2915 Email: gareth.odonnell@dit.ie Research Centre / Institute Name and Website (if applicable) Not applicable Scholarship Details The stipend is €10,000 per annum. The cost of EU academic fee will be covered for the duration of the scholarship. NonEU applicants are eligible to take up the scholarships, but they will be required to fund the fee differential. Schools will make available a desk space, PC along with a modest bursary for travel, conferences and some limited materials. Subject Area New Materials & Devices Title of the Project Novel Surface Peening Processing for Improved Fatigue Strength and Surface Protection of Metallic-based Components Project Abstract Currently shot-peening is used extensively to improve fatigue strength for components which experience cyclic mechanical loading conditions such as automotive suspension springs and dynamic hot-section turbine engine components. This process can have the added benefit of creating a surface finish which is more resistant to wear and corrosion mechanisms. Shotpeening involves the generation of residual compressive stress on the surface of components by micro-scale plastic deformation in the form of cratering, which in turn mitigates the generation and subsequent propagation of fatigue induced cracks. It is envisaged that an alternative roll/press-peening processing, which is the subject of this study, can be used to produce the same and potentially better fatigue strength, wear and corrosion resistances than the traditional and less environmentally sound shot-peening processing. This project entails the systematic and rigorous investigation of the processing factors which influence the peening process. Subsequently, with the use of validated numerical modelling and systematic process design, the roll/press-peening process is developed so that experimental testing can be used to evaluate the effectiveness of the process to enhance fatigue characteristics and both wear and corrosion resistance, ultimately resulting in a proof of this proposed roll/press-peening process concept. The research question being addressed is as follows: Can a roll/press-peening process be developed to replace and improve on the traditional shotpeening process from the point of view of processing cost, environmental impact, fatigue strength improvement and both wear and corrosion resistances? Please indicate the student requirements for this project Min. 2.1 BSc (honour) or BEng (honours) in Mechanical Engineering, Metallurgical Science, or a closely related area. Deadline to submit applications (only for funded projects) 5.00pm, 17th Sept, 2015