vikas rajan

advertisement

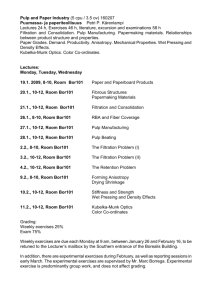

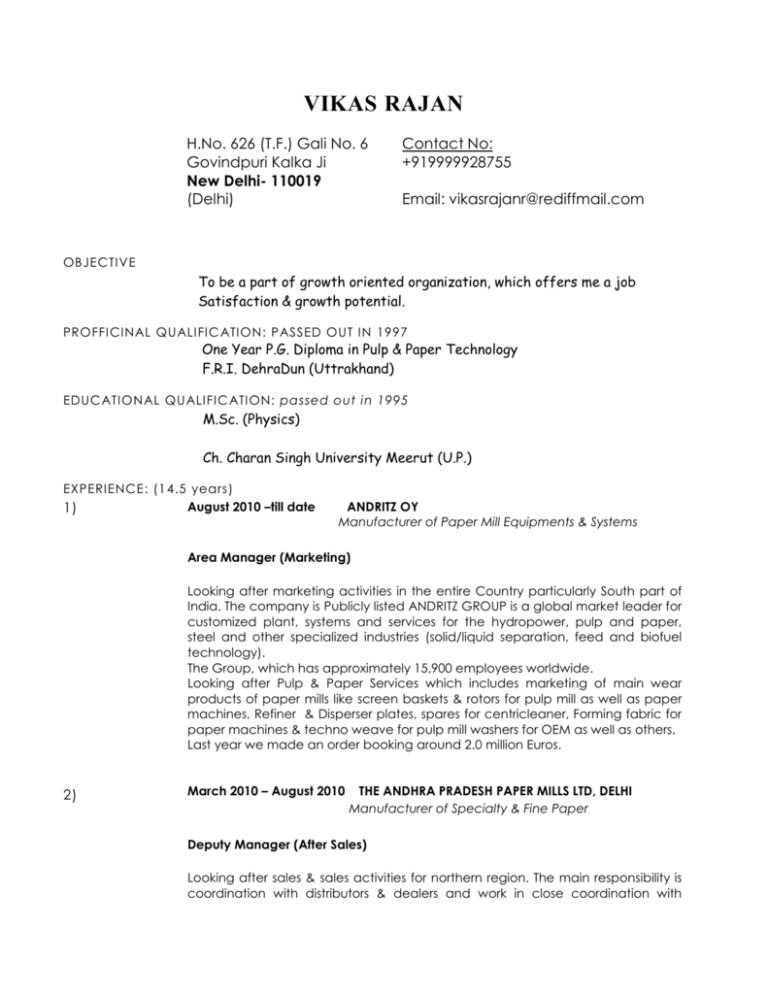

VIKAS RAJAN H.No. 626 (T.F.) Gali No. 6 Govindpuri Kalka Ji New Delhi- 110019 (Delhi) Contact No: +919999928755 Email: vikasrajanr@rediffmail.com OBJECTIVE To be a part of growth oriented organization, which offers me a job Satisfaction & growth potential. PROFFICINAL QUALIFIC ATION: PASSED OUT IN 1997 One Year P.G. Diploma in Pulp & Paper Technology F.R.I. DehraDun (Uttrakhand) EDUCATIONAL QUALIFIC ATION: passed out in 1995 M.Sc. (Physics) Ch. Charan Singh University Meerut (U.P.) EXPERIENCE: (1 4.5 years) August 2010 –till date 1) ANDRITZ OY Manufacturer of Paper Mill Equipments & Systems Area Manager (Marketing) Looking after marketing activities in the entire Country particularly South part of India. The company is Publicly listed ANDRITZ GROUP is a global market leader for customized plant, systems and services for the hydropower, pulp and paper, steel and other specialized industries (solid/liquid separation, feed and biofuel technology). The Group, which has approximately 15,900 employees worldwide. Looking after Pulp & Paper Services which includes marketing of main wear products of paper mills like screen baskets & rotors for pulp mill as well as paper machines, Refiner & Disperser plates, spares for centricleaner, Forming fabric for paper machines & techno weave for pulp mill washers for OEM as well as others. Last year we made an order booking around 2.0 million Euros. 2) March 2010 – August 2010 THE ANDHRA PRADESH PAPER MILLS LTD, DELHI Manufacturer of Specialty & Fine Paper Deputy Manager (After Sales) Looking after sales & sales activities for northern region. The main responsibility is coordination with distributors & dealers and work in close coordination with corporate marketing, manufacturing units, logistic team & customers. Responsible for all after sales activities & new product development. Good exposure of ERP system: SAP. 3) November 2006 – March 2010 ARJUN TECHNOLOGIES (I) LTD. CHENNAI Manufacturer of Paper Mill Equipments & Systems Deputy Manager (Marketing) Looking after marketing activities in the entire Northern & Eastern part of the Country. Arjun Technologies is a sister concern of Arjun Chemical and C.P.Engineering. It is a company promoted by an NRI Mr P. Chandrasekhar staying at Germany. The company is having Technical Collaborations with various world leaders overseas Paper Mill equipment manufacturer and System suppliers. Some of the associates are listed below: ABB Cellier – France Coating Colour Kitchen for Paper & Paints industries C P Engineering GmbH2nd hand Paper Machinery business ECH Will GmbH A- 4 cut size automatic sheeter, stationary and cutters Kadant Black Clawson Inc – U.S.A. Kadant Lamort – France Neyrtec environment –France Pemco Inc U.S.A. Sernagiato S.p.A – Italy Solaronics IRT – France Wrapmatic S.p.A. – Italy Arjun Chemicals Ltd. Chennai ETC etc. : Pulping Equipment i.e. BSW, Continuous Digester, oxygen de-lignifications, Brown Grade Waste paper pulping : White grade Waste paper Pulping and deinking system. : Air handling system : Automatic cut size sheeters : Sludge Handling System : Infra Red heating System ; Automatic Real and Ream handling system : Sizing Chemicals Achievements: In The year 2007 – 2008, we made the record order booking and invoicing. The present year is also looking very encouraging as far as our business goes. We are already having order 18 crore for the year 2008 – 2009 along with around U.S D $ 4.0 Million for the various Principals and collaborators. Most of the order booking stands from Delhi office I have developed excellent relationship with all senior technical personal. 4) January 2006 – Nov 2006 CIBA SPECIALTY CHEMICALS (I) LTD. MUMBAI Manufacturer of Specialty Chemicals Account Manager 5) Responsible for BILT unit: Ballarpur account. Looking after Dual Polymer Retention system (Polymer & Bentonite Silica) running on all six machines, OBA, Krofta chemical, cationic Starch & Dyes. First time AKD introduced by Ciba & plant trials taken in northern region of India & implemented. October 2004 – January 2006 IVAX PAPER CHEMICALS PVT. LTD., HYDERABAD Manufacturer of Specialty Chemicals Application Manager Responsible for northern region of India. First time Alkaline Sizing (AKD & ASA) plant trials taken in wheat straw furnish & implemented (Shreyans Industries limited, Unit: Ahmedgarh). Alkaline Sizing (ASA & cationic rosin) & Dual Retention system (Polymer & colloidal silica) plant trials taken in bagasse furnish & implemented (Century Pulp & paper Nanital). Also worked on lab Evaluation for the alkaline sizing chemicals (AKD, ASA & ent furnishes (100% Bamboo, 60% Bamboo + 40% H.W., 100% Waste paper, 60% Bagasse + 40% H.W., 90% Wheat Straw etc.). 6) June 2001 – October 2004 Ballarpur Industries Limited, Ballarpur Manufacturer of Specialty & Fine Paper Executive- R&D/ QAS 7) To conduct Paper Quality Survey to assess the quality gap between Bilt and competitors product. Worked on hypo free bleaching sequence & implemented in plant. To reply customer complaints related paper quality. Developed process for Slime control in paper manufacturing process. Implemented ISO-9001 (2000) at work place. Worked on development of multipurpose paper Dec 1998- June 2001 Central Pulp & Paper Research Institute Saharanpur Premier Pulp & Paper Research Institute in India Senior Scientific Assistant Worked on Waste Paper Processing (Deinking etc.) Different pulps to improve properties of weak pulps (Bagasse, straws etc) Evaluation of papermaking chemicals (Sizing, Retention Aids etc) Handle all latest instruments used for pulp and paper testing. Aug 1997- Dec 1998 8) Star Paper Mills Limited, Saharanpur Manufacturer of Paper Shift Incharge: Stock Preparation Plant Worked in the capacity of Shift Incharge in Stock Preparation plant With good exposure of process & Machinery. Handle the shift independently. OTHER SKILLS: Well conversant with “TQM Philosophy” through ANNAR consultancy & Implemented this philosophy at work place. Knowledge of computer for MS-office application, and ERP (Oracle Process Management & Optivision System). RESPONSIBILITIES HAN DLED: Development Activity relating to Product improvement/ Development as per satisfaction of Customer Requirement. Paper making process monitoring as a proactive TQM approach towards problem solving. To conduct Paper Quality Survey to assess the quality gap between bilt and competitors product. To Develop & Implement Quality Systems at work place. PAPER PUBLISHED: Paper entitled “ Wet web properties of some indigenous pulps and possibilities to improve the paper machine runnability for bagasse pulp”. was published in 4th International Non Wood Pulping & Papermaking Conference held in Jinan, China on 18 – 21 September 2000. Paper entitled "Wet strength paper repulping: Laboratory evaluation" was published in International Papermaking and Environment Conference held in China on Oct. 22-24, 2003 (organized by Tianjin University of Science & Technology and China Technical Association of Paper Industry). Paper entitled “Role of Chemical Additives On Paper Cleanliness” received First prize in IPPTA Zonal Seminar on Chemical Additive in Paper manufacturing held in Nagpur (M.S.) on 2-3 July 2004. Paper entitled "Wet strength paper repulping: Effect of process variables" was published In APPITA journal July 2004. Present PACKAGE: PAY PERSONAL DETAILS: 720000/-pa Date of Birth: 17/05/1973 Father’s Name: Shri Daya Chand Linguistic Proficiency: English and Hindi Passport no. J4786293 Marital Status: Married & 10 years son & 2 years old months daughter S/o Shri Daya chand Teacher, H.No. 86 Adarsh Colony Bhopa Road Muzaffarnagar (U.P) PIN: 251001 Permanent Address: