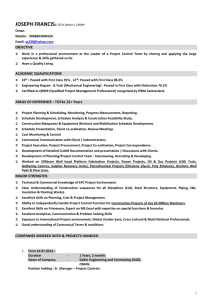

Job Applied for Project Coordinator (Structural & Piping)

advertisement

Subhash Umanandan Tel.: +971 50-050-3415424 E-mail: saswin2002@gmail.com Address: OGASCO Musafah Project Department –Abu Dhabi. United Arab Emirates OBJECTIVE Aspire for challenging and dynamic career in Project Manager/Operation Manager/Area Manager/Construction Manager for Piping, pipeline, Structural & Mechanical Engineering of Oil & Gas – Offshore Platforms / Onshore Projects/Das Island/ZADCO Project Zirku Island. PROFESSIONAL SUMMARY A resourceful Project Manager holding 23+ years of proven experience covering Piping, pipeline, Structural & Mechanical Engineering in EPC projects in the field of Oil & Gas, Onshore & Offshore Platform Projects, Creative and smart in working, Leadership skills, Self-disciplined and innovative. Well experienced in Project Execution, Coordination / Construction Management and PMT activities, Documents review & comments, etc,Having experience in all stages of operations (i.e. Basic detail Engineering, execution phase of project and commissioning),Committed learner, self-driven personality with positive attitude, effective organizer of work load and a strong team player with good communications and interpersonal skills and pursue continuous development. Ability to thrive in fast-paced scenarios. Awareness of international codes (ASME, API, BV, U-Stamps) practiced in now a day projects. Having experiences in Pressure vessel, Evaporator, Legs, Spud cans for Jack up-Barge ,Buoy,Plems,Fenders,Onshore-Oil-Gas Modules, Offshore-Semi Submersible Drilling RigsOutfitting, Living Quarters, Topside Decks-Jackets, Skid-Piping Manifold, Skid-Structural Packages, Steel structures for power-Oil Refinery-Chemical Plants. Managing and Coordination with all discipline-Contracts-Estimation,Engineering,ADCOPMT,ADCO-PMC,HSE,Sub-contractors,vendors,quality,QA,Planning,ProjectControl, Production, procees,electrical,piping,pipeline,construction,civil,draftsman,instrumentation,hydrotest,prec omissioning, commissioning, trial test, handover team. Managing and coordination of Subcontractors SOW’S-OHL EPC Contractors-PB Power Engineering and design works, topography and geotech survey, Pilling, structural steel lattice fabrication and erection works, pre-commissioning and commissioning works.CO2 Pipeline route and approaching stations topography and geotech survey for pipeline alignment sheet and profile survey, coordinates, baseline, grading and foundation level etc,arranging topography survey and Geotech investigation reports,FTV-PROCLAD Pipe supply and cladding works, Pipeline CP works, Pipeline external coating works,NDT-PWHT Works, Civil field and lab testing works. Details of Nature of Duties and Responsibilities for Project Manager in Project Management Team and Construction Team: As a Project Manager/operation Manager/Construction Manager I am responsible for the activities (related to the discipline) with Client, vendors and sub-contractors. The detailed responsibilities include but not limited to following: Page 1 of 8 Subhash Umanandan Study Contract Documents, Drawings and Specification for the projects, Identification and highlighting PMT about the issues that needs particular attention. Providing Method Statements and Risk assessments as per project requirements, providing all necessary information’s and coordinates with the Planning section for the preparation of Planning Package. Arranging KOM, (PIM)-Pre Inspections Meeting, Weekly coordination meeting with client, concerned discipline as per project requirements, Co-ordination with the Engineering office and subsequently with the assigned Engineering Project Manager (EPM) to ensure Work Priorities. Follow-up with the Engineering Department for the preparation of fabrication drawings to meet the established work schedule. Determination and assigning of Engineering Priorities, Preparation of Shop Drawings & Issue complete package for fabrication including drawings, materials to fabrication yard based on the priorities. Co-ordination with Fabrication Department to ensure the detailed work plans are understood and accordingly execution plan are in place. Follow up materials delivery according to the production requirement and highlighting any remarkable delay for management action. Co-ordination with the Quality Assurance Section (QAS) and Welding Engineers to ensure the timely preparation of QC Procedures and ensuring issuance of same in time for approval from client. Ensuring Construction procedures prepared in adherences with company’s QA Manual, contract specification and standard work practice. Study the fabrication drawings in detail, define scope of works, Monitor the works progress with yard and discuss for corrective actions as required from time to time. Maintaining Track Records for each and every fabricated/painted item and updating of records for easy reference. Coordination with Offshore/ Onshore sites, warehouses and fabrication yards to ensure the timely availability of Construction materials as per the requirements. Co-ordination with Company and Client HSE department and providing necessary inputs for the preparation of Project HSE plans, Risk Assessments etc, Attending construction related issues and sought the help of Engineering, if necessary. Resolve work related problems and recommend measures to improve productivity. Ensure that standards for safe working conditions are observed. Attend site problems associated with project and propose solutions/ Alternatives and obtaining of Client’s approval. Ensure pressure Test packs is issued and Testing activities are carried out in time following with clearance of punch list before load out of Deck. Identification of offshore scope and preparation of job cards. Coordination for offshore activities and ensure all document, material are delivered in time and any technical issues are resolved in time. Submission of As-built document to Client MAJOR PROJECTS INVOLVED WORK EXPERIENCES (23+ years EPC experience in the field of Oil and Gas) From Nov 2014 to Still working) Project Manager – Structural/Piping (OGASCO-ALGHAITH) – Abu Dhabi-RAK, United Arab Emirates (www.ogasco.ae) Reporting to PD & MD OGASCO-AL-GHAITH is one of leading EPC Contractors in the Gulf involved in the business of the following: Client of the projects: ZADCO-Offshore –Zirku Island / ADOC/Hyundai Engineering-HDEC/ L & T UAE-INDIA/ADCO/TAKREER Approved Project Manager for ZADCO Operational team by Abu Dhabi and Zirku Island and Approved Project Manager for Hyundai Engineering ZARB Project.ZADCO Projects Page 2 of 8 Subhash Umanandan SOW Prefabrication of piping spools and site installation for under ground drain line of Temp header and permanent header. Engineering SOW shall be site survey, detailed drawings preparations and submission to client. Scanning survey at site for underground pipeline in live plant thorough cable detector and GPR assessment, topography and geotech survey analysis. Detailed drawing and survey reports submission and obtaining approval to carryout site civil excavation works .Temp header installation and Tie-in connection with existing drain no 3 without affecting any process line. Will follow HSE Rule and regulations as per ZADCO site requirements. All personnel to arrange Medical, HUET Training, HSE Induection,H2S Training, confined space training, PTW Etc. Coordination with all sub-contractors for site scanning works, civil works, NDT, Scaffolding works. Arranging pre-commissioning required items Breaking of existing paving and carryout excavations by manually. Identify the existing corroded pipe line and replace by safe manner by using cold cutting methods. Installation of permanent header as per removed corroded pipe line routings and carryout hydro testing stage by stages above similar sequences. To carryout final inspection then proceed for blasting/paining and wrapping of newly installed spools. Commissioning and trail testing newly installed lines. Obtain PAC from client. ADOC Project SOW Covers prefabrication of cladded spools fabrication, hydro testing and painting and delivery to client site. Cladding works for all pipes and fittings shall be carried out CLADTEK in UAE& Badam sites. Coordination of all sub-contractors and vendors cladding works and materials delivery. Pre-fabrication of basket strainers, hydro testing and painting works for non coded type. HDEC Prefabrication of piping spools and pipe supports including hydro testing and painting works. SOW for piping 400000 ID and Pipe supports 1000 Ton. All documents downloading and uploading by FTP Server connected Spool gen cad software. L& T Project for TAKREER Piping prefabrication of piping spools including hydro testing and delivery. SOW for piping 90000 ID for 6Months project completion Handled multi million projects Overall budgeted cost of average + 200 Million USD SOW Roles and responsibilities. From July 2013 to Oct 2014) Project Manager – Structural/Piping -- ALSA Engineering Company (ALSA) – Abu Dhabi-RAK, United Arab Emirates (www.alsaeng.ae), Reporting to AM & VP-Projects and Onshore ALSA Engineering Company is one of leading EPC Contractors in the Gulf involved in the business of the following: Client of the projects: DUSUP / DUGAS / DUBAL /RAKGAS /ROTARY /ADCO /FORTUNE /QPD /CEC / ADCO-PMC EPC and EPIC Project Management providing Engineering, Procurement and Construction services, Handled Qatar petroleum development (QPD) project of Shell and Tube exchangers ASME-U Stamp code and design works. ADCO -CO2 BAB FAR North and Rumaitha WAG Injection pilot project works for CO2 Gas line and production line approximate 126KM Pipe line, Piping, Block valve stations,RDS-8 Station, east and north cluster flanks, ADCO Projects Subcontractor SOW Coordination including OHL, CP, Cladding for line pipes, Topographical and Geographical survey etc. Handled RAKGAS Project WWTP Modification works- Piping-Structural-Mechanicalelectrical-Instrumentation pre-fabrication, erection, installation, pre-commissioning and commissioning and obtaining PAC etc,Onshore Modification and Shut-down and Onshore Hook-up, Pre-commissioning and Commissioning, Onshore Pipe laying and Onshore Plants Construction SOW Review. Arrange, KOM with client, Arrange PIM with client, Coordination with all discipline managers-Piping,structural,Equipment's,civil,Electrical,Instrumentation,HRPage 3 of 8 Subhash Umanandan HSE,planning,contracts,QA-QC,Engineering,Logistics,Procurement, Review daily progress weekly progress, Coordination with subcontractors, vendors etc, Review cost control and alerting with project control manager, Daily-weekly-monthly meeting with client, Coordination with pre-construction, construction team, Review HSE-Quality-Productivity status, Daily-Weekly-monthly reports submission to senior management Review 3 weeks look ahead schedule with internal and client. Review protect schedule with planning team Review procurement status weekly and expedite with vendors. Review productivity report with over run MHRS Comparisons, Review submission of all VDR documents on time. Arrange to get approval from client on time, coordinate with blasting and painting team for QC Cleared items to proceed. Coordination with planning team for monthly progress submission on time. Make sure PAF submission on time by monthly reports. Final Submission of As-Built MRB with soft copy to client, coordination with client for clearing payment on time. Review claims and variation on time. Raise TQR/Claims and expedite for approval, Load out by barge procedures submissions and get approval from client, Coordination with logistic and rigging team for load out thorough barge or by road. Arranging PAC or Final clearance certificate from client, GPC Yard having pre-assemblyassembly-load out-jetty facilities, GPC Yard having pre-assembly-assembly-load outjetty facilitates with Dry-dock. Supply and Construction of Storage Tanks, Pressure vessels, Heat exchangers, Manufacture and Supply of Separators, Pressure Vessels, Columns, Modules, Packaged Equipment and other related products for Petrochemical Projects ADCO - Shah Gas Development projects-Hameem-’Abu Dhabi- New GAS Plant construction-EPCClient Saipem---US$ 1000 Million---(www.dodsaleng.com) (From June 2012 to July 2013) Worked as a Construction /Area Manager –Structural/Piping --Dodsal Engineering-UAE Reporting to Sr.Project Manager The Project scope of EPC-1 is mainly to: Co-ordination of the review and comment of detailed EPC contractor engineering drawings, specifications and document submittals for construction released drawings, Unit no 730 consist for 4 Pipe racks with 3 leveling for the length of 400 Mtr long x 12 Mtr wide x 30 Mtr Height. Managing and handling responsibilities of Structural Pipe racks columns, beams, sub structures preassembly, erection, alignment, release for equipment’s erection and piping activities, Managing and handling responsibilities of Each leveling pipe spools prefabrications, erection or installations, inspection, NDT, Final dimensional recheck, PWHT, Blasting-Painting, hydro test package preparations, line walkthrough, testing, reinstatement and handover works etc. Managing and handling responsibilities of Equipment’s erections of fin-fan coolers assembly, vessels, heat exchangers, knockout drums etc,Detailed analysis of the EPC contractors construction schedule and monthly report Daily interface with Plant Area Manager For client Saipem and to coordinate contractor and subcontractor activities for the planned construction activities daily and weekly plan. Ensure all contractor and subcontractor insurance policies required under the related contracts are in effect. Ensure safe working practices and HSE are adopted and adhered to throughout the project. Ensure Contactor and subcontractor compliance with QA/QC obligations Handover the units to saipem, after pre-commissioning & commissioning work. Page 4 of 8 Subhash Umanandan Gulf Marine and Maintenances Offshore Services (GMMOS)—Fred Olsen-Wind carrier jack up leg platforms and spud cans (www.gmmos.com) Client lamprell/Technip/Petrofac—US $ 200 Million (From Jan 2011 to June 2012) Worked as a Project Manager – Structural/Piping -----------Reporting to Sr.Project Manager Project is involved to carryout the Design Engineering, Procurement, Fabrication, Onshore Commissioning, Load out, Sea Fastening Transportation to Company's designated Offshore Locations. Managing and supervising of all fields of engineering activities during construction phase of the project. Preparation, discussion and finalization of the Contract technical annexure up to Contract signature, Planning and organization of engineering activities, according to the Contract. Coordination and follow-up of progress meetings and technical review sessions with Customer and client. Expediting of Customer’s / PMT requests, change orders identification. Coordination with all departments HSE, QA-QC, Engineering, Planning, Production, Procurement, Logistics, Accounts, Bidding-Estimation, Top-Management, Clients, subcontractors, Vendors, TPI etc. Review and discussion of technical and commercial proposals, freezing of scope of work, deliverables and man-hours. Coordination between Outsourcing Company and internal engineering departments, Coordination and follow-up of monthly technical review meetings and progress meetings. Certification and monitoring of monthly physical progress and invoicing progress. Management of claims, change orders follow-ups Assistance to the Commercial Manager in facilitating business development. International Management and construction company (IMCC-GPC-GSME-IMAC-TGPC)—EGTLProject works/ HE-PV Manufacturing/Evaporators. (www.imcc.ae;gsme.ae) Client: KBR/ Saipem/Technip/ADGAS/ADMA-OPCO/Dodsal/Foster wheeler / Petrofac / KCC / ONGC-—US $ 1000 Million (From Aug 2004 to Jan 2011) Worked as a Sr.Project Engineer cum Sr.Production Engineer– Structural/Piping ------Reporting to Project Manager/Operations Manager ONGC–India Project is involved carryout Launch Truss Jacket and Platform, Design Engineering, Procurement, Fabrication, Onshore Commissioning, Load out, Sea Fastening Transportation to Company's designated Offshore Location, Installation & Hook-up and Commissioning for Well Platform, submarine pipelines and associated topside modifications on the existing Platforms An EPC project, joint venture with Technip (Abu Dhabi).GPF is envisaged as a standalone Process platform with independent utilities / supporting facilities except Electric Power, Diesel and Service/Fresh Water to minimize the dependence on facilities. However, for flexibility purpose, interconnection of utility systems with existing facilities will be provided Reviewing of Vendor Packages and Technical Bid Evaluation of piping materials as well as mechanical equipment’s. Leading the team of engineers, designers / draftsman and provide technical support and guidance. Interacting with various disciplines, vendors and clients. Review and commenting of Technical Queries and Concession Requests (piping, pipeline and mechanical), raised by project contractor. Monitoring of the progress of the project work with respect to schedule, man hours spent keeping in view the quality aspect. Participating in vendor’s acceptance test demonstrations, Fabrication and offshore installation of Wellhead Jackets, Topsides and Modules Offshore Modification and Shut-down and Offshore Hook-up, Pre-commissioning and Commissioning, SPM and PLEM Fabrication and Installations Method statements, Monthly payment advice /materials tracking summary/consumables over all review/project ManPage 5 of 8 Subhash Umanandan hours with over run Man-hours analysis Method statement/Procedures follow up client/QC Dossier submissions to client /HSE-Report/project schedule. Extra claims tracking report etc. Direct and manage project development from beginning to end. Define project scope, goals and deliverables that support business goals in Collaboration with senior management and stakeholders. Drawings comparison between IFB vs. IFC to find measurement changes / variations, Material takeoff from drawing and prepare scope of work for issue subcontract, Find variations and cost impacts and cost estimation for NOV, FCR & ECN & FWD (mechanical fabricated equipment and site fabrication, erection, commissioning and civil etc.) Calculation the weights and paint area of structural steel, pipes and estimate cost as per Contract ,Monitor offshore barges standby and raise proposals to Company, Preparation of Change Proposal (Technical & Commercial) and submit to Client and negotiate with clients for Change Orders, Develop full-scale project plans and associated communications documents. J Ray McDermott (Mc Dermott)—onshore and Offshore Project services Client: KBR/ADGAS/ADMA-OPCO/ONGC-—US $ 2000 Million (www.jraymcdermott.com) (From Dec 2002 to Aug 2004) Worked as a Technical Assessor – Structural/Piping -----------Reporting to Sr. Assessor or Training Manager This project is EPC Contracts to procure, build and supply project requirements. The Project involved construction, engineering, procurement, fabrication, transportation and installation of a new tie-in platforms and modification to three of existing platforms. Monitoring and assessing assessors' development and practice. Conducting formative (interim) and Summative internal verification. Monitoring candidate records, progress and achievements. Working closely with the department manager on the development of the departmental systems, procedures and staff competence. Conducting standardization meetings within each occupational area. Conducting assessor or delivery team meetings. Answering all queries relating to the assessment and verification process. Supporting assessors in specific ways - such as providing for simulations and special needs. Staff retention and recruitment. Staffing levels and structures: allocation of internal verifiers to assessors and allocation of learners to assessor. Overseeing the effective running of the departments. Meeting awarding body requirements. Ensuring that center policies and procedures are adhered to, and monitored and evaluated on a regular basis. Tracking and monitoring learners' progress. Providing support meetings for staff and learners. Providing administrative support to all staff and learners. Storing and recording completed awards for the verification process. Candidate induction packs. Specifying assessors' and internal verifiers' job roles. Standards and documentation. Dealing with appeals and problems with learners, their line managers or staff. Providing resources for staff training and development. Costain Abu Dhabi (Costain) ----DAS ISLAND- ADGAS Project works---Offshore Project Expansion works & NBTC-Kuwait Equate Ethylene-Projects (www.costain.com) Client: ADGAS-—US $ 500 Million (From Dec 2000 to Aug 2002) Worked as a Site Engineer– Structural/Piping -----------Reporting to Area Manager This project is a lump sum, procure, build and supply contract. The Project involved construction, engineering, procurement, fabrication, transportation and installation of a new tie-in platform and modification to six of existing platforms Offshore Field. Besides these structures the project structures the project also had a scope for installation of 16” sub-sea flow line and 42” trunk line to carry the crude to the onshore processing stations. Page 6 of 8 Subhash Umanandan Managing and supervising of the project engineering disciplines included Process and Safety, Piping, and Pipeline works. Managing and supervising of all field engineering activities during construction phase of the project. Leading off the team of engineers, designers / draftsman and provide technical support and guidance Coordination with project procurement and construction departments. Liaison with Client of the project and engineering managers. Review and commenting on all Technical Queries & Concession Requests raised by project contractor Supervising sub-contractors and liaison with their representatives. Client interface on all engineering matters. Participating in vendor’s acceptance test demonstrations. Project monitoring actual vs. plan. Scheduling and Cost control. Work within a team of Piping Engineers from through scoping and detailed engineering to constructions. ALSUWAIDI-Saudi Arabia—ARAMCO-Projects- Uthamaniya Gas Plant expansion works Client: ARAMCO—US $ 2000 Million (www.alsuwiadi.com) (From Oct 1997 to Dec 2000) Worked as a Site Engineer – Structural/Piping -----------Reporting to project Manager Engineering, Procurement, Construction and pre-commissioning optimum surface facilities for Phase-I Development, The Project includes the Fabrication, Transportation, and Installation, Precommissioning and Commissioning of Production Platforms, Bridges, Pipelines etc. Managing and supervising of the project engineering disciplines included Process and Safety, Piping, and Pipeline works. Managing and supervising of all field engineering activities during construction phase of the project. Leading off the team of engineers, designers / draftsman and provide technical support and guidance Define scope of activities; assign workloads, review standards/procedures. Estimating and Budgeting for Piping scope for all phases of a project Check the piping layout designs, quality of engineering Documentation and installation, conduct analysis needed Liaise with clients, vendors, engineers, and other disciplines. Keep to agreed schedules and budgets for all deliverables. Participate in the professional development of less experienced members of the department/team. Hanil Development Company--- (HANIL) Project works---Onshore Project Expansions Client: SABIC/Fertilizers company —US $ 300 Million (From Sep 1994 to Sep 1997) Worked as a Site Engineer– Piping -----------Reporting to Area Manager Managing and supervising of all construction groups including Welding, Piping, Pipeline, Mechanical, Civil / Structural /Surveying. Electrical, Instrumentation and Control, Quality Control, Planning and Project Control as well as Contract, Administration, Accounts and General Service’s departments Project monitoring actual vs. plan. Coordination with project procurement and Engineering departments. Maruthi Builders -- (MARUTHI) Project works---Power & Fertilizers Plant Project Expansions Client: NLC-Power plant/Blue star—US $ 60 Million (From May 1990 to Sep 1994) Worked as a Site Engineer– Piping -----------Reporting to Sr.Resident Engineer Managing and supervising of all construction groups including Welding, Piping, Pipeline, Mechanical, Civil / Structural /Surveying. Liaison with Client of the project and Site Manager. Supervising sub-contractors and liaison with their construction managers. Client interface on all construction matters. Interacting with vendor’s site representatives. Scheduling and Cost control. Page 7 of 8 Subhash Umanandan PERSONAL DETAILS Profile : Male, 42, Married, 18/03/1972 Nationality : Indian Languages : English, Tamil, Malayalam & Hindi Passport & validity : J6489102 & 06-June2021 Licenses : India & UAE Valid till 2017 EDUCATION Diploma in Mechanical Engineering, SAP-University, Chennai-India TRAININGS / COURSE & COMPUTER SKILLS MS Office applications & Auto CAD SAUDI ARAMCO Work permits courses / IIF Training for EGTL-KBR Project/ADCO Medical and H2 Training/ ZADCO Medical/HUET Training MS Projects / MS Word /MS-PPT/ERP/SAP/ Spools Integrity software WIS-SIS/ Spool gen software NVK-UK Based assessment training in J Ray McDermott Company in Dubai Various Safety courses such as First Aid and Confined Space entry training. REFERENCES Available upon request time Page 8 of 8 Subhash Umanandan