HAZOP_RECORD_SHEETS-final

advertisement

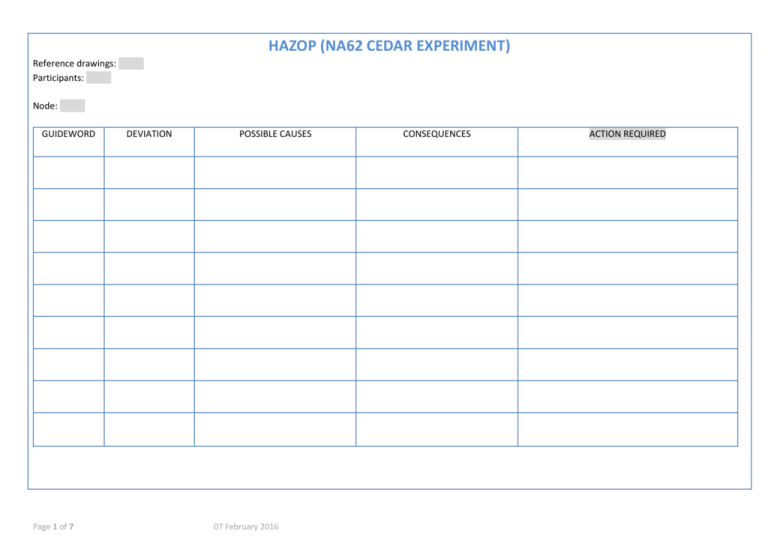

HAZOP (NA62 CEDAR EXPERIMENT) Reference drawings: Participants: Node: GUIDEWORD Page 1 of 7 DEVIATION POSSIBLE CAUSES 07 February 2016 CONSEQUENCES ACTION REQUIRED Node: Purging the N2 line plus detector GUIDEWORD DEVIATION POSSIBLE CAUSES CONSEQUENCES ACTION REQUIRED NONE FLOW Hand valve closed Power cut No N2 flow to the detector Downtime. Have to open hand valves 1. NONE LEVEL Not relevant Not relevant Not relevant NONE MAINTENANCE Human error Can lead to problems 2. Establish a maintenance schedule of for all relevant equipment items. REVERSE FLOW False manipulation could cause gas flow from the pumping system REVERSE EQUIPMENT Wrong mounting of equipment Slow pressure increase through CEDAR and all other gas lines. Pump out gas and refill with N2 again Bad behaviour detected at commissioning and repair done MORE OF MORE FLOW Mass flow controller does not see forward flow gas sent through CEDAR to the vent line. Opening one of the entrance valves or change the pressure set point. Mass flow controller has to have a well chosen maximum setting. MORE OF PRESSURE Human error, allowing gas coming from the pump line More gas released through vent line Safety release valve will switch to the vent line MORE OF TIME Computer crash 3. Define minimum time for purging with N2 and include in procedure. PART OF COMPOSITION Human error Watchdog will notice and switch off all input and outputs Does not matter really Wrong gas mixture, possibility to get flammable gas into the detector PART OF OPERATION Control by-passed in part by human error Wrong gas mixture, possibility to get flammable gas into the detector 4. Password protection.Write a record in log-files of bypassing. .Follow-up and avoid in the future Page 2 of 7 07 February 2016 Put contacts on input valves that give an alarm via the computer. Put mixer in stop mode. See Action No. 1. Node: Filling procedure (as pure as possible, 1 permille) to a pressure precision of 0.5 mbar GUIDEWORD DEVIATION POSSIBLE CAUSES CONSEQUENCES NONE FLOW Hand valves closed Procedure does not work REVERSE FLOW False manipulation could cause gas flow from the pumping system MORE OF PRESSURE Pressure safety valve broken or set point pressure gauge broken Slow pressure increase through CEDAR and all other gas lines. Pump out gas and refill with H2 again Spotted by set point (or safety valve) detector and stop Issue an alarm and stop MORE OF TEMPERATURE (External) fire MORE OF TIME PART OF COMPOSITION Wrong valve position Interlocked FLOW Failure or unlikely leak of pneumatic valves and leaking non-return valves. Wrong manipulation H2 into N2 or vacuum lines. Does not matter too much OTHER THAN Page 3 of 7 Risk of explosion Level 3 fire alarm in building and/or mixer region Level 3 interlock shuts off H2 supply. ACTION REQUIRED 5. Set pressure relief of PSV-6074 to below safety limit for windows. 6. Consider the need for local smoke detection and/or temperature sensors in Cedar region (contact HSE Unit, Fire Prevention). 7. Limit presence of combustible materials, e.g. insulating material of CEDAR. Procedure stops. Have to investigate and start again. 07 February 2016 8. Pumps, flow meters, valves etc. will be ATEX rated. Check with HSE Unit, Electrical Safety when ordering equipment. 9. Consider safe locations for venting. Node: Empty the CEDAR to a pressure of 0.1 mbar GUIDEWORD DEVIATION NONE FLOW REVERSE POSSIBLE CAUSES CONSEQUENCES No pumping, Loss of time. Need to repair problem FLOW Pump not working Power cut Pneumatic valve closed Pump connected wrong (unlikely) MORE OF PRESSURE Leak Fix leak and pump longer PART OF OPERATION No vacuum in beam line Risk of window rupture FLOW Nitrogen safety valve in wrong position N2 wasted OTHER THAN Page 4 of 7 07 February 2016 ACTION REQUIRED Seen in commissioning 10. Interlock emptying with vacuum pressure in blue tube Node: Pressure scan , i.e. lower H2 pressure stepwise to a lower value within 0.1 mbar GUIDEWORD DEVIATION NONE FLOW REVERSE FLOW LESS PRESSURE POSSIBLE CAUSES CONSEQUENCES ACTION REQUIRED Pump or valve or mass flow controller broken. Hand valve closed. When in vacuum, valve from exhaust opened. Scan does not work. Need to identify and fix causes 11. Consider removing manual/hand valve HV-5035 from vent line. Could suck in air into Cedar. Several valves prevent this 12. Add non-return valve from vent line to pump Two valves failing at the same time Too low pressure, Get warnings 13. General remark: update P&ID with modifications to system and to reflect the instrumentation in place (e.g. indicate which instruments give alarms, actual position of PSV-6074 directly on CEDAR Vessel, position of manual/hand valve HV-6005) Page 5 of 7 07 February 2016 GUIDEWORD PARAMETER MEANING NONE FLOW LEVEL MAINTENANCE NO FLOW VESSEL EMPTY NOT CARRIED OUT REVERSE FLOW EQUIPMENT REVERSE FLOW INSTALLED WRONG WAY ROUND MORE OF AND LESS OF FLOW TEMPERATURE PRESSURE LEVEL TIME WRONG FLOW WRONG TEMPERATURE WRONG PRESSURE WRONG LEVEL WRONG TIME PART OF COMPOSITION OPERATION MISSING COMPONENT NOT COMPLETED PROPERLY OTHER THAN FLOW OPERATION FLOW MISDIRECTED DIFFERENT PROCEDURE USED WHERE ELSE FLOW COMPOSITION FLOW DIRECTED ELSEWHERE AS WELL CONTAMINANT PRESENT Page 6 of 7 07 February 2016 Page 7 of 7 07 February 2016