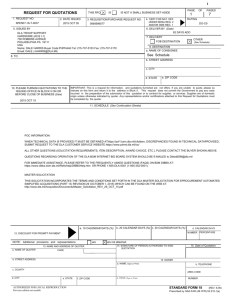

Supplementary Table 1 DLA production from various waste products

advertisement

Supplementary Table 1 DLA production from various waste products Micro-organism Raw material Optical purity Carbon source Lactic acid Yield Yield (g/l) (g/g) References YP/S Lactobacillus Delbrueckii Sugarcane 98.3% Molasses Sucrose 120 0.95 Calabia and Tokiwa 2007 Lactobacillus amylovorus ATCC 33620 Potato 30% Starch 4.2 - Linko and Javanainen 1996 Lactobacillus coryniformis ssp. torquens ATCC 25600 Cellulose 100% Cellulose 24 0.89 Yanez et al. 2003 Lactobacillus sp. LMI8 Whey with Corn steep liquor 98% Lactose 52.3 - Lima et al. 2010 Lactobacillus delbrueckiiLD 0028 Rice 96.9% Maltose 83.5 - Lee 2007 Lactobacillus delbrueckii Sp. lactis ATCC 4797 CWP 98.2% Lactose 24.3 0.49 Present Study References: Calabia B P and Tokiwa Y (2007) Production of D-lactic acid from sugarcane molasses, sugarcane juice and sugar beet juice by Lactobacillus delbrueckii. Biotechnol Lett 29:1329–1332 Linko Y Y, Javanainen P (1996) Simultaneous liquefaction, saccharification, and lactic acid fermentation on barley starch, Enzyme Microb. Technol. 19,118–123. Lima C J B, Coelho L F and Contiero J (2010) The Use of Response Surface Methodology in Optimization of Lactic Acid Production: Focus on Medium Supplementation, Temperature and pH Control. Food Technol. Biotechnol. 48 (2) 175–18. Lee C W (2007) Production of D-Lactic Acid by Bacterial Fermentation of Rice, Fibers and Polymers. Vol.8, No.6, 571-578. Yáñez R, Moldes A B, Alonso J L, Parajó J C (2003) Production of D(–)-lactic acid from cellulose by simultaneous saccharification and fermentation using Lactobacillus coryniformis subsp. torquens, Biotechnol. Lett. 25, 1161–1164. Supplementary Table 2 Composition of SCWP and CWP Component SCWP CWP Lactose (g/l) 50 35.43 Protein(g/l) 5.3 5.21 Mg(mg/l) 36 101.2 P (mg/l) - 9.64 K (mg/l) Zn (µg/l) Na(mg/l) 1300 210 260 1173 315.61 Ca (mg/l) 291 321 Fat (%) 0.2 0.193 Ash (g/l) - 1.11 1 0,9 y = 1,3182x + 0,1298 R² = 0,9563 0,8 q DLA 0,7 0,6 0,5 0,4 0,3 0,2 0,1 0 -0,1 0 -0,1 0,1 0,2 0,3 0,4 0,5 0,6 µ (h-1) Supplementary Fig.1 Leudeking-Piret parameters for L. lactis in bioreactor experiment, α and β values are 1.31 and 0.129 respectively. Higher value of α indicates DLA a qDLA primary metabolite: The Luedeking–Piret model was used to describe the DLA production, where q DLA is specific DLA productivity (g DLA g-1DCW l-1), µ is specific growth rate (h1 ), α is the growth-associated constant, and β is the non-growth-associated constant. Experimentally determined biomass and DLA concentration values were employed to estimate specific growth rate (using logistic model) and specific DLA production rate. 3,5 3 DLA (g/L) 2,5 2 1,5 1 0,5 0 CWP CWP+AC CWP+CH Supplementary Fig.2 Comparative analysis of DLA production by L. lactis in 3 different production media viz., WP, WP+AC, WP+CH under shaking incubation conditions. All experiments were performed using 5 % v/v inoculum, at 37°C and 200 rpm. Supplementation of casein hydrolysate with CWP was found to yield high titer DLA.