Progress Report 1

advertisement

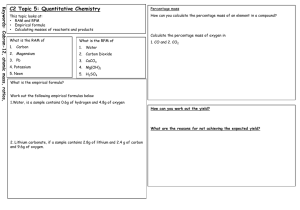

Garner Group Progress Report 1 12/11/15 Hans Cocks Background From the beginning of my tenure until now, my work has been directed towards two main problems. The first concerning the synthesis of protected methyl-a-Dmannopyranoside carbohydrate derivatives for use in GPI related syntheses, and the second involving the synthesis of cysteine thiol protecting groups for use in solution and solid-phase peptide chemistry. Scheme 1 and 2, respectively, relate to the exclusive acyl and benzyl protection of secondary alcohols contained in the methyl-a-D-mannopyranoside sugar. The involved reactions served as a good introduction to the structural diversity of natural sugars and are quite relevant considering the modification of natural polysaccharides is gaining increased attention in the field of nano-medicine. Successful preparation and preservation of stereochemistry in these protected sugars allows them to be utilized in constructing sugar moieties which are ligated to other moieties in the convergent synthesis of the CD52 GPI anchor found in leukocytes, epididymal cells, and sperm. The primary unprotected alcohol site is for attachment of the next sugar, while the protected alcohol groups are cleaved in the final global de-protection step of the GPI synthesis. Schemes 3 and 4, respectively, outline the synthesis of base and acid labile cysteine thiol protecting groups. These groups may be used in divergent orthogonal peptide synthesis strategies and are preferred over other protecting groups because they enable the prevention of racemization. Each group is, additionally, stable to removal of the other under appropriate conditions, thus allowing for, in a strategy utilizing both groups, selective de-protection of distinct cysteine thiol groups. Preparation of the base labile 9fluorenylmethylthiol molecule, shown in scheme 3, is, in use, comparable to other cysteine SH protecting groups such as the 2-(2,4dinitrophenyl)ethyl (Dnpe) group, though S-Fm offers increased compatibility with other sulfur protecting groups. Preparation of acid labile S-Tmob (2,4,6-trimethoxybenzylthiol) is ongoing; the protected group it introduces is analogous to the p-methoxybenzyl (Mob) protecting group commonly used for the same purpose, though S-Tmob has improved stability. Successful preparation of S-Tmob and SFm will allow for diversity, control, and stability in the synthesis of cysteine containing peptides. Results and Discussion Scheme 1 - (reactions 1-3) Preparation of: Methyl 2,3,4-tri-O-acetyl-alpha-D-mannopyranoside-6-ol All reactions for scheme 1 proceeded well with little complications. Primary alcohol A was treated with trityl chloride, pyridine was added to dissolve the components and scavenge HCl, leading to formation of the trityl protected sugar B in 44% yield after purification via flash chromatography in 80% EA:Hex. Product was compared against a previously prepared pure standard and characterized via H1 and C13NMR which indicated high purity. Trityl-protected B was then acetylated with acetic anhydride to protect the secondary alcohols leading to formation of the completely protected alcohol C. Pyridine was again added to scavenge protons while serving as the solvent. TLC in 10% EA:Hex indicated reaction had gone to completion and the mixture was purified via flash chromatography in the same solvent system. The purified product, obtained in 80% yield, was checked for purity against a previously prepared standard in 40:60 EA:Hex and was characterized via H1 and C13NMR spectroscopy. Protected sugar C was then de-tritylated by stirring with iron(III) chloride hexahydrate to form the free primary alcohol D. TLC against a previously prepared pure std. in 40:60 EA:Hex indicated starting material to be in the crude mixture which was removed through purification using flash chromatography eluting and running the column with 20:80 EA:Hex. The pure product D, was thus obtained in 75% yield and the product was characterized via H1 and C13NMR spectroscopy. Scheme 2 – (reactions 4-8) Preparation of: Methyl 2,3,4-tri-O-benzyl-alpha-D-mannopyranoside-6-ol The target product D of scheme 2 was never obtained due to an excess amount of previously prepared material already existing. Methyl-alpha-D-mannopyranoside(A) was treated under the same conditions as found in step 1, scheme 1 to produce the trityl protected alcohol B in 58% yield(see exp. Trt-Man-4). Experiments 5 and 6 designated as 5-M-Trt-Bn and 6-M-DeTrt-Bn encountered complications and no usable data was obtained. The trityl alcohol B was then successfully benzylated via addition of NaH followed by BnBr leading to the fully protected intermediate C. After work-up the obtained product was crystallized from CHCl3 adding hexanes to incipient turbidity landing a final yield of 30%. Transition to scheme 3 occurred in the next reaction which was a second preparation of the fully protected sugar C(Bn-Trt-M8), of which the experiment was never completed. The fully protected sugar C was stored in a dessicator and left for use at another time. Scheme 3 – (reactions 9-15) Preparation of: 9-fluorenylmethylthiol Table 1: Summary of reactions performed over course of scheme 3 Product Attempted Alcohol 2 Tosylate 3 Thioacetate 4 Target S-Fm 5 (Exp #) Trial 1, MP (Exp #) Trial 2, MP (Exp #) Trial 3, MP (9F-OH-9) 25% yield, MP = 95-97oC (9H-Fm-Ts-10) failed reaction (9Fm-Sac-13) 35% yield, MP=66-67oC (9Fm-SH-15) 86% yield, MP = 33-34oC (9-Fm-OH-11) 25% yield, MP = 82-85oC (9Fm-Ts-12) 55% yield, MP = 106-108 - - - - (9Fm-Ts-14) 44% yield MP=105-107oC - Realizing the final product of scheme 3 proved to be difficult for a variety of reasons. Small mistakes and lots of learning took place during this synthesis. Upon successful isolation of each intermediate the products were characterized via melting point and H1NMR spectroscopy. H1NMR inspection revealed all products to be relatively pure. Below are excerpts, with the exception of 9F-OH-9 and 9Fm-Ts-10, from prepared eBook entries regarding mechanisms and difficulties encountered during each step of scheme 3: Regarding formation of alcohol 2 (purified via recrystallization): @9F-OH-9: Use of the word ligroin resulted in recrystallizing from a low boiling solvent, the issue has since been reconciled, 50% recovery was achieved. MP of 95-97oC indicates the product to be relatively pure. @9Fm-OH-11: NaH deprotonates fluorene at the 9 position. The fluorene anion then attacks the ethyl formate at the carbonyl carbon leading to loss of ethanol and the desired aldehyde condensate intermediate. The aldehyde intermediate is then reduced to a primary alcohol via addition of NaBH4. After working up the carbaldehyde intermediate an attempt was made to ‘push’, based on the possibility of tautomerization and hydration equilibriums, the yellow spot in the mixture to the desired aldehyde product. Product was lost over several operations yielding no change in the presence of the yellow spot, ending with reacidification of the mixture with GAA which was then concentrated without an additional wash of sodium bicarbonate leading to the increased usage of sodium borohydride mentioned above. After complete reduction and filtration, the crude product, tinted slightly yellow, weighed 4.8086g (24.503mmol) corresponding to a yield of 49.1%, with an M.P. of 83-87 C. TLC revealed 3 spots in the crude mixture. Recrystallization resulted in the disappearance of 1-spot, and 50% recovery. A yellow insoluble trapped on the bottom of the flask was set aside and the filtrate was saved for if and when another attempt at harvesting crystals could take place. The MP for this reaction was 16oC below that found in literature after recrystallization indicating a good amount of impurities were trapped in the crystal. Regarding formation of tosylate 3 (purified via incipient of turbidity using hexanes): @9Fm-Ts-10: Excess pyridine was added to the reaction mixture, which after sitting over a period of 3 days, lead to decomposition of the desired product. In retrospect, the base lability of the Fluorenylmethyl group made this decomposition easy to predict. @9Fm-Ts-12(14): The alcohol on compound 2 attacks the Sulfur atom of the paratoluene-sulfonyl chloride. The chlorine atom leaves grabbing the H+ ion at the original alcohol site. Pyridine functions as an acid scavenger shifting equilibrium to the product. Care should be taken not to let the reaction run to long, as excess pyridine may react and deprotonate the 9H hydrogen ion leading to loss of the tosylate and formation of an alkene by-product. Reactions 9Fm-Ts-12 and 9Fm-Ts-14 both proceeded smoothly with no complications and good purity. Regarding formation of thioacetate 4 (purified via flash chromatography in 1-4%EA:Hex) : @9Fm-Sac-13: The tosylate provides a good leaving group for substitution via delocalization of the electrons it contains; the 18crown6 promotes the ability of the sulfur atom to attack at the ch2 methyl site by chelating the potassium ion leading to attachment and loss of the tosylate. This reaction is simple enough and should be high yielding due to the reagents involved. I expect the next attempt at this reaction to proceed with no problems. The majority of product loss for this reaction occurred due to difficulty with getting good separation in the flash column leading to multiple purification trials before separation was successful. The product was, in hind-sight, almost entirely isolated during the first 3 columns but, due to researcher error, the product containing fractions were mis-identified; future scenarios such as this may be prevented by rough estimation of partition coefficients for compounds in the crude mixture via the vandeemter equation. The primary compound responsible for lack of proper separation (the major impurity) was ‘a greasy mess’ which was isolated and characterized via HNMR. Regarding formation of thiol 5, target molecule (purified via flash column in 2% EA:Hex): @9Fm-SH-15: DIBAL-H, existing as a dimer and exhibiting electrophilic properties, is first attacked by the carbonyl oxygen, it then gives its hydrogen to the carbonyl carbon, forming a stable tetrahedral intermediate below -70oC. Excess (2.2 equiv.) of DIBAL-H is used for this reaction, I hypothesize, due to the ability of the adjacent dimerized aluminum to ligate to the nearby Sulphur atom after the attached DIBAL has given away its hydrogen thus reforming a more stable dimer, and lowering the effective concentration of DIBAL-H in the reaction mixture. Quenching of this reaction requires two equivalents of HCl, one equivalent to give to the Sulphur atom thus creating a good leaving group, and another to reform the original DIBAL-H dimer immediately prior to its decomposition into the corresponding Aluminum oxide salt. Completion gave a high yield but there is a slight amount of solvent in the product as seen in the HNMR spectrum. However, melting point of the isolated product was within the bounds of that found in literature indicating good purity. This reaction, though tricky, proceeded well with no issues. Scheme 4 – (reactions 16-19) Preparation of: (2,4,6-trimethoxyphenyl)methanethiol Scheme 4 is currently in progress; this project originally started after complications arose in synthesizing the target acid labile cysteine protecting group 4b.Conversion of alcohol 3 to thiol 4b, via formation and hydrolysis of the thiuronium intermediate salt 4a was attempted twice (see experiments Tmob-SH-16/17), with consumption of the remaining in-house 2,4,6-trimethoxybenzyl alcohol before developing the full scheme. The supplied literature (see references) indicated quantitative yield to be achievable in high purity with no purification apart from simple liquid-liquid extraction. Tmob-SH-16, the first attempt, resulted in a 52% yield, but the product didn’t melt indicating all of it to likely be a salt. Notes on the reaction indicate: the biggest deviation in this reaction occurred when water was lost during reflux. Somehow the mixture became acidified and the product or byproducts became a salt. >> Future reaction should be done with excess and solid NaOH instead of a molar solution. HNMR characterization of Tmob-SH-16 revealed lots of overlapping peaks at 3.5ppm with integrations way above expected. Tmob-SH-17, the second attempt, went smoother achieving a 60% yield. Upon taking a melting point, much of the material melted around 50oC (10oC below literature), but an un-melted portion still remained. This was hypothesized to be the unreacted thiouronium salt which was reformed after acidification of the mixture following hydrolysis of 4a. Upon preparing the NMR sample it was noticed there was a small amount of insoluble material in the obtained product, the sample was passed through a syringe filter before going into the NMR tube. HNMR revealed the sample to be relatively pure thus at another time it may be possible to put the thiol in solution and filter off the insoluble material to obtain the pure product. To assist in peptide synthesis, the Stmob-SH-17 product was dissolved in dry ethyl acetate, the insolubles filtered out using a syringe filter, and the mixture concentrated to near dryness. Complete dryness, or the consistency expected, was unable to be achieved and multiple High-Vac pumps were used to try and dry the product. Subsequently the container with the product was evacuated, flushed with argon, tightly sealed with parafilm and stored in the refrigerator. Two weeks later, the product was put back into solution for an NMR attempt, and frustratingly, more of the insoluble material had formed. This newly forming material could be the result of oxidation yielding the disulfide. To prevent this decomposition in future reactions, lyophilizing the product before storage could help dramatically. Other conditions are also being explored, including using acetonitrile and tosic acid instead of water, acetone, and HCl. Use of Cysteine residue stabilizers such as TCEP (tris(2-carboxyethyl)phosphine) is also being considered. TCEP is a water soluble disulfide bond reducing agent, and is available immobilized on agarose to assist in its removal upon reduction of the disulfide to the free thiol. Starting from scratch, scheme 4 was initiated, (Stmob-ald-18) from compound 1, 1,3,5-trimethoxybenzene, to yield compound 2, 2,4,6-trimethoxybenzaldehyde in 74% yield and high purity as indicated by H1NMR and MP analysis. The reaction proceeds through the vilsheimer-haack reaction mechanism, first with formation of the vilsheimer reagent, a chloroiminium salt of DMF and the added phosphorous(V) oxychloride, which allows attachment of the aromatic ring thus proceeding to another iminium ion which is hydrolyzed with water to form the desired benzaldehyde derivative. Sodium carbonate is added to break down the phosphorodichloridic acid and HCl formed during the reaction. No purification was needed, this simple, neat, reaction proceeded quickly and there were no complications. Conversion of aldehyde 2 to alcohol 3 Stmob-OH-19 initially proceeded well with complete formation of the alcohol taking place. Unfortunately the product did not precipitate as expected (considering the pure standard is a white crystalline material) and the mixture was not properly worked up in time. Over the days the mixture sat on the bench, several decomposed variations of the target molecule formed, to avoid this in the future, the mixture should be liquid-liquid extracted immediately after decomposing the remaining hydrides with acetic acid. This issue follows the same principles of decomposition, in terms of lability, as that which occurred in the 9Fm-Ts-10 experiment. Scheme 4 will be revised and restarted from benzene derivative 1, ideally with no more complications. References and Notes Carb. Res,, 179 (1988) 37-50 J. Org. Chem, 45(21), 1980. P. 4251 Gu, X. et al; Org. Lett. 2004, 6(19), 3285-3288, p. S4 Bandgar, B.P.; Totre, J. V. (Piramal Life Sciences Lt.). Cytokine Inhibitors. WIPO(PCT) Patent, Publication Number: WO 2011/121505 A1. Application Number: PCT/IB2011/051269. (Pg 44); Oct. 6, 2011 Crich, D; Kasinath, S; Guo ,S; Org. Lett. 2007, 9(22), 4423-4426, p.S3 p. S4. Crich, D; Kasinath, S; Guo ,S; Org. Lett. 2007, 9(22), 4423-4426, p.S3 p. S3. Synth. Comm., 28(17), 3219-3223(1998)