07720_Roof Hatches

advertisement

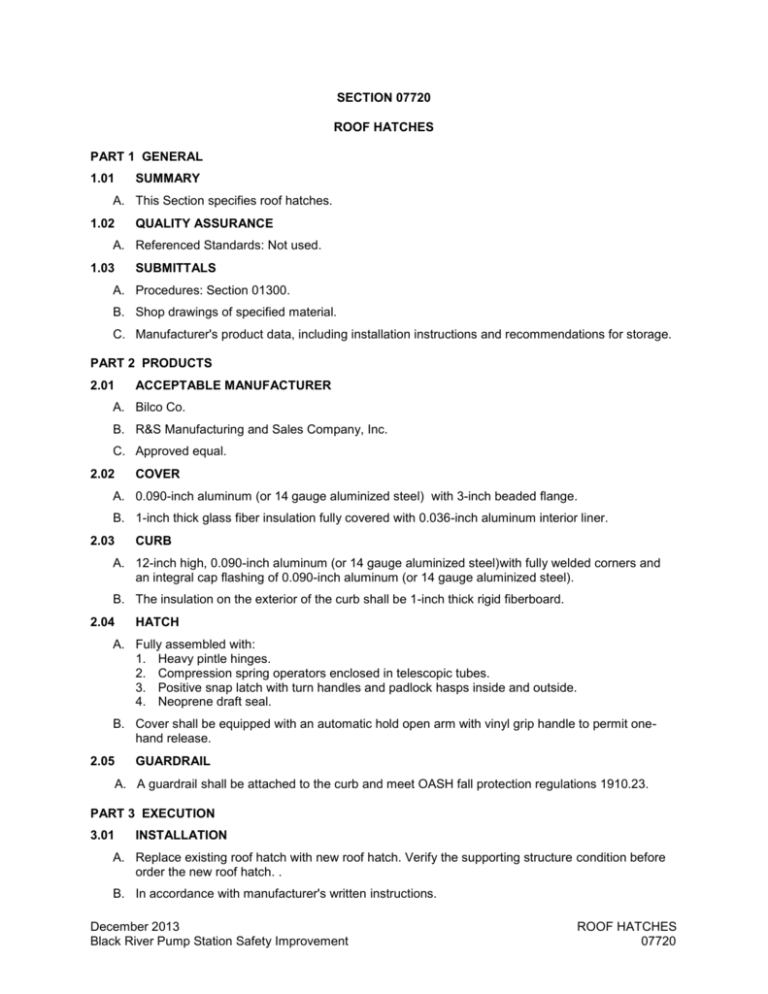

SECTION 07720 ROOF HATCHES PART 1 GENERAL 1.01 SUMMARY A. This Section specifies roof hatches. 1.02 QUALITY ASSURANCE A. Referenced Standards: Not used. 1.03 SUBMITTALS A. Procedures: Section 01300. B. Shop drawings of specified material. C. Manufacturer's product data, including installation instructions and recommendations for storage. PART 2 PRODUCTS 2.01 ACCEPTABLE MANUFACTURER A. Bilco Co. B. R&S Manufacturing and Sales Company, Inc. C. Approved equal. 2.02 COVER A. 0.090-inch aluminum (or 14 gauge aluminized steel) with 3-inch beaded flange. B. 1-inch thick glass fiber insulation fully covered with 0.036-inch aluminum interior liner. 2.03 CURB A. 12-inch high, 0.090-inch aluminum (or 14 gauge aluminized steel)with fully welded corners and an integral cap flashing of 0.090-inch aluminum (or 14 gauge aluminized steel). B. The insulation on the exterior of the curb shall be 1-inch thick rigid fiberboard. 2.04 HATCH A. Fully assembled with: 1. Heavy pintle hinges. 2. Compression spring operators enclosed in telescopic tubes. 3. Positive snap latch with turn handles and padlock hasps inside and outside. 4. Neoprene draft seal. B. Cover shall be equipped with an automatic hold open arm with vinyl grip handle to permit onehand release. 2.05 GUARDRAIL A. A guardrail shall be attached to the curb and meet OASH fall protection regulations 1910.23. PART 3 EXECUTION 3.01 INSTALLATION A. Replace existing roof hatch with new roof hatch. Verify the supporting structure condition before order the new roof hatch. . B. In accordance with manufacturer's written instructions. December 2013 Black River Pump Station Safety Improvement ROOF HATCHES 07720 C. Plumb roof hatch drain to allow drainage of roof hatch. D. See Section 15050 for material requirements. END OF SECTION December 2013 Black River Pump Station Safety Improvement ROOF HATCHES 07720