40-2014 ACTIVITY HAZARD RISK ASSESSMENT

advertisement

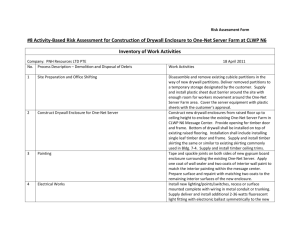

RESOURCES PTE LTD Co. Reg. No. 200101754G 5 9 W O O D L A N D S I N D P K E 2 , & S I N G A P O R E 7 5 7 4 7 6 T E L : 6 4 6 4 9 9 5 9 F A X : 6 4 6 4 9 9 4 9 02 June 2014 From: Senior Safety Manager To: Executive Manager Subject: # 40-2014, ACTIVITY HAZARD RISK ASSESSMENT FOR CEILING AND WALL HACKING AT NANYANG TECHNOLOGICAL UNIVERSITY Ref: (a) Ministry of Manpower Regulations Regarding General Safety and Health 354A 1. Per reference (a), this risk assessment was completed to identify hazards that pose risk to workers, evaluate those hazards for severity and likelihood of occurrence, and recommend corrective actions that will eliminate or minimize hazards associated with hacking operations. Currently the following areas have been identified for this type of work: a. Hall 8 b. Hall 11 2. This AHA will be reviewed periodically and updated as needed to reflect changes in working conditions, processes or addition of new materials or equipment. Introduction………………………………………………………………………………………………………….Page 1 & 2 Inventory of Work Activities………………………………………………………………………………….Page 3 1 Activity Risk Assessment Matrix……………………………………………………………………………Page 4 Activity Based Risk Assessment Form……………………………………………………………………Page 5 Fall Protection Plan……………………………..………………………………………………………………..Page Listing of Competent Persons……………………………………………………………………………….Page 6 3. Please address any questions or concerns to me at 8205 8249 or lee_wilson@pnhgrp.com. Respectfully, T. L. Wilson 2 Risk Assessment Form #40-2014, ACTIVITY HAZARD RISK ASSESSMENT FOR CEILING AND WALL HACKING OPERATIONS Inventory of Work Activities Company: PNH Resources PTE LTD No. 1 2 Process Description Preparation of the worksite and prepare appropriate safety precautions. Assemble the appropriate tools 3 Prepare for demolitions 4 Debris removal 5 Removal of the footing of the wall 6 Clean-up 02 June 2014 Work Activities Erect appropriate barricade to restrict access by unauthorized personnel. Post required safety warning signs to alert all that this is a construction zone and must be avoided without appropriate safety equipment including hard hats, steel toed shoes, eye/face protection and hearing protection. Appropriate tools will depend on the scope of work but may include large sledgehammers, ball-peen hammers, impact drills, chisels, use of jackhammers, shovels and wheelbarrows. Drill small holes in surface to be hacked, holes should be about 8 inches apart and drill holes in the mortar on the corner of each block of a concrete block wall. Chisel into the holes with a ball-peen hammer to widen them to about 3 inches or 7.62 cm in diameter. Begin removing sections of wall with a sledgehammer. If the wall is over the worker’s head, make the first strikes with the hammer at chest level, making sure that the worker moves after each blow to a clear spot. If it is a lower wall, start at the top of the wall and work your way down. Pick up the rubble with shovels and place in wheelbarrow. Remove debris from the premise by the wheel barrow and place In a suitable receptacle for ultimate removal from the campus. Remove the footing of the wall with a jackhammer. After the footing has been removed use the shovel to dig up any remaining debris and transfer the debris as stated above to a suitable receptacles for ultimate removal from the campus. Employ the use of brooms and mops as necessary to remove all remaining debris and reduce the level of dust as much as possible as this may impact the finishing work. 3 #40-2014 ACTIVITY HAZARD RISK ASSESSMENT – FIVE POINT MATRIX EMPLOYED TO QUANTIFY RISK – 02 June 2014 Risk Criteria Severity (1-5, Lowest – Highest) Likelihood ( 1-5, Lowest - Highest) 1-Negligible Injuries: slight injury or health effect, 2-Minor Injuries: Injury or ill health requiring first aid treatment only 3-Moderate Injury: Injury requiring medical treatment or ill health leading to disability 4-Major Injury Disability: serious injury or life threatening occupational disease 5-Castrophic: serious injury resulting in fatality or irreversible health damage with death 1-Rare: very unlikely to happen, 2-Remote: not likely to happen most of the time, 3-Occasional: likely to happen sometime, 4-Major Injury Disability: likely to happen several times regularly, 5-Almost Certain: Likely to happen Risk Level (Severity x Likelihood) Trivial Risk : Tolerable Risk : Moderate Risk : Substantial Risk : Intolerable Risk : 1 to 2 (L) 3 to 9 (L) 10 to 19 (M) 20 to 24 (H) 25 (H) - First aid treatment injury, minor cuts or bruises, clean-up effort for environmental impact - First aid treatment Injury, minor cuts or bruises, clean-up effort for environmental impact - Temporary disability, lost time injury, outpatient treatment, minor or short term environmental impact - Serious Injury, permanent disability, major disruption and damage to equipment or structure, significant environmental - Fatality or fatalities, serious injury, permanent disability, major structural or equipment damage, detriment environmental The table above provides numerical methodology to better prioritize hazards. These values are the criteria for the Activity-Based Risk Assessments beginning on the following page. No catastrophic risk of any certainty was identified. Risk is calculated mathematically by multiplying severity of the operation by the likelihood an accident will occur. Generally risk levels calculated at 9 and below are considered acceptable, manageable risk. This does not preclude the need to try and mitigate all risk to the lowest possible level. However, those above nine should receive additional scrutiny to determine what steps are available to reduce overall risk including, administrative controls, substitution of a higher hazardous material for a less hazardous material, use of engineering controls or use of personal protective equipment (PPE). 4 Risk Assessment Form Activity-Based Risk Assessment Form Company: PNH RESOURCES PTE LTD Process/Location: #40-2014, Electric Arc Welding Approved by: (Name, designation) (Date) Bradamente Amoroso (Martin) Project Manager 02 June 2014 1. Conducted by: (Names, designations) (Date) Lee Wilson Senior Safety Manager 02 June 2014 Last Review Date: Next Review Date: Hazard Identification Paul Lim Operations Manager 02 June 2014 2. Risk Evaluation 01 December 2014 3. Risk Control 1a 1b 1c 1d 2a 2b 2c 2d 3a 3b No Work Activity Hazard Existing Risk Control (if any) SevErity Additional Risk Control Motor vehicle (MV) accident resulting in injury or fatality 2 Likel yhood 2 Risk Level Delivery of tools, equipment and materials to the worksite via the public road systems Site Preparation – Erection of Protective/ Safety Barricades, Posting of Safety Signage Possible Accident/ Ill Health & Persons at Risk MV operator and others who may be assisting him in this transportation evolution. 4 Document any an all training and inspections associated with this phase of the operation. Action Officer Designation Senior Safety Manger and Project Manager 2 2 4 Recommend that usage of eye protection be emphasized before hacking start and then several times during the project. Project Manager and Senior Safety Manager 1 2 Sight Hazard from flying debris Musculoskeletal from moving/ manipulating safety barricade materials. Personnel performing the construction/ installation of the safety/protective barricades. Personnel performing the construction/ installation of the safety/protective barricades. MV operator maintains a current and appropriate MV operator’s license Vehicle is inspected prior to use to ensure it is in good condition for use on public roadways. All PNH workers are issued sight protection and receive training on sight conservation several times during the calendar year. All PNH workers receive training at least 3 times annually on the risk of musculoskeletal injuries including sprains, strains, muscle tearing and ligament damage. 5 2 2 4 Sight Protection equipment should always be inspected prior to use. Ensure that all training includes: 1. Lift with the legs, 2. Keep back straight, 3. Hold load close to body, 4. Don’t twist with load, Project Manager and Senior Safety Manager No 3 Work Activity Hacking of Ceilings and walls. Hazard Sight Hazard due to significant amounts of flying debris – High Eye Hazard operation. Noise creating a hearing hazard. Musculoskeletal Disorders including vibration injuries. Workers may be at risk of developing a secondary form of Reynaud’s Syndrome or “Vibration White Finger” (VWF) Possible Accident/ Ill Health & Persons at Risk Workers assigned to perform hacking on both ceilings and walls. Workers assigned to perform hacking on both ceilings and walls Workers operating hacking tools for prolonged periods and/or in awkward positions. Existing Risk Control (if any) Wearing of safety glasses and/or other eye face protection as needed. Wearing of hearing protection. Take frequent breaks as needed to alleviate muscle and joint fatigue. Training should include a discussion on methods of improving circulation (i.e. massaging the extremities on breaks) Vary work positions during the day, trade off jobs with other works. In addition, hacking on the ceiling places workers at risk of developing sprains, strains, ligament or other types of musculoskeletal disorders. 6 SevErity 3 3 3 Likel yhood 2 2 2 Risk Level 6 6 6 5. Inspect planned path first. Additional Risk Control Hacking of the ceilings will place workers at increased risk due to the fact that they will be looking up. Chipping goggles may need to be supplied in order to avoid eye injuries. Eyes must be flushed for 15 minutes to remove debris. Single hearing protection should be adequate. A noise survey can be requested from the Safety Office to rule out potential requirement four double protection. When purchasing new tools for these types of operations, ergonomic support should be one of the major considerations. Report all suspected instances of the development of Reynaud’s Syndrome so that they may be properly investigated. Action Officer Designation Senior Safety Manager Project Manager Project Supervisor Senior Safety Manager & Project Manager & Project Supervisor. Senior Safety Manager Project Manager Project Supervisor Use of Working at Height (WHE) Equipment to access ceiling areas when hacking. 4 5 Ensure Inspection Is completed on any type of WHE equipment used during this phase of work. Ensure that all inspections are documented. Injury/fatalities from falls. Work Activity Hazard Debris Removal – hacked materials shall we swept up, scooped and place in wheel barrow(s) for removal to debris staging area. Musculoskeletal – from repetitive bending, lifting and transporting of debris. Possible Accident/ Ill Health & Persons at Risk Personnel involved with debris removal Cleanup/ Housekeeping and General Restoration of Worksite – Ensure that the worksite is thoroughly cleaned and returned to a condition supporting normal See sections A, B, and D in the fall protections plan for; 3 3 9 Scaffolds, WHE & PFAS and ancillary equipment. Work above 3 meters requires that the Project Supervisor obtain a working at height chit from the Safety Department. For use of scaffold she the Fall Protection Plan on Page 24. Existing Risk Control (if any) Training to cover: Severity 2 Likel yhood 2 Risk Level 4 It is imperative that correct procedures be used when working at height. Work above 1.8 meters (6 feet) requires the use of personal fall arrest systems. Inspections shall include: 1. Harness webbing; 2. Snaps, hooks & karabiners; 3. D Rings & 4. Buckles and Adjusters Senior Safety Manager Additional Risk Control Action Officer Designation Senior Safety Manager Review good work practices to be observed when avoiding these types of injuries. Take frequent breaks as needed to alleviate muscle and joint fatigue. Training should include a discussion on methods of improving circulation (i.e. massaging the extremities on breaks) Sight Hazard when conducing sweeping, high cleaning, and general cleaning. Workers assigned to complete the cleanup phase of this project. Vary work positions during the day, trade off jobs with other works. Sight Protection – issue to all PNH workers Training – All PNH personnel receive training regarding both sight conservation and avoidance of musculoskeletal injuries. 7 Project Manager Project Supervisor Project Manager Project Surpervisor 2 2 4 Training for MSDs as discussed in section 2 above. Always report any and all incidences of musculoskeletal disorders to the Safety Department and Project Supervisor. Project Manager and Supervisor and Senior Safety Manager. occupancy Work Activity (5) Hazard Possible Accident/ Ill Health & Persons at Risk Existing Risk Control (if any) Musculoskeletal Disorders (MSD) - when lifting, carrying, and otherwise moving equipment, excess materials and tools from the worksite 8 Severity Likel yhood Risk Level Additional Risk Control Action Officer Designation QUALIFICATIONS AND POINTS OF CONTACT FOR THIS PROJECT FROM PNH RESOURCES PTE LTD AND GOODMNAN ENVIRONMENTAL PTE LTD (APPLICABLE MONTH) 2014 Competent/Qualified Personnel: (These should be tailored to fit the project) Lee Wilson - 8205 8249 QP/ First Aid CPR/ Heat Stress Program/ Respiratory Protection Program/ Hearing/Sight Conservation Program/Training Coordinator Ms. Thazin Nwe (Jennifer) 8522 6014 HAZMAT Coordinator Lim Joseph – 9683 7072 CP/ Scaffolds/ Fall Protection Eng Yong Chye – 9626 9262 PNH Project Manage/CP/ Electrical/ First Aid CPR/Lock Out/Tag Out Equipment Used : Hand and Power Tools First Aid Kit Eyewash Station Fire Extinguisher Inspection Requirements: Daily inspection of equipment for damage or leaks before use. Inspect PPE daily and before use. Inspect first aid kit at least weekly. Visual inspection of Fire extinguisher daily. Daily housekeeping of work areas Daily site safety inspection by Safety Manager and project quality control. 9 Training Requirements: First Aid / CPR Emergency Telephone Number Daily / Weekly Safety tool box Meetings and safety training.