AHA #8 FOR CONSTRUCTION OF DRYWALL

advertisement

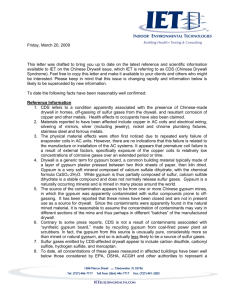

Risk Assessment Form #8 Activity-Based Risk Assessment for Construction of Drywall Enclosure to One-Net Server Farm at CLWP N6 Inventory of Work Activities Company: PNH Resources LTD PTE No. Process Description – Demolition and Disposal of Debris 1 Site Preparation and Office Shifting 2 Construct Drywall Enclosure for One-Net Server 3 Painting 4 Electrical Works 18 April 2011 Work Activities Disassemble and remove existing cubicle partitions in the way of new drywall partitions. Deliver removed partitions to a temporary storage designated by the customer. Supply and install plastic sheet dust barrier around the site with enough room for workers movement around the One-Net Server Farm area. Cover the server equipment with plastic sheets with the customer’s approval. Construct new drywall enclosures from raised floor up to ceiling height to enclose the existing One-Net Server Farm in CLWP N6 Message Center. Provide opening for timber door and frame. Bottom of drywall shall be installed on top of existing raised flooring. Installation shall include installing single leaf timber door and frame. Supply and install timber skirting the same or similar to existing skirting commonly used in Bldg. 7-4. Supply and install timber ceiling trims. Tape and spackle joints on both sides of new gypsum board enclosure surrounding the existing One-Net Server. Apply one coat of wall sealer and two coats of interior wall paint to match the interior painting within the message center. Prepare surface and repaint with matching two coats to the remaining interior surfaces of the new enclosure. Install new lighting/points/switches, recess or surface mounted complete with wiring in metal conduit or trunking. Supply deliver and install additional 2-36 watts fluorescent light fitting with electronic ballast symmetrically to the new ceiling lay-out, complete with required control circuit, diffuser/louver and wiring in metal trunking or conduit connected to the existing DB’s. Trace existing electrical circuits, then remove and/or relocate all affected fittings, power points, wirings and conduits in the way of construction. Re-label and update electrical circuit distribution for all the affected power and lighting circuitry. Supply and install new and approved master switch for secondary emergency power shutdown to control all incoming supply to the existing server farm equipment at the newly renovated area complete with all of the necessary ancillary equipment. Risk Assessment Form Activity-Based Risk Assessment Form Company: PNH RESOURCES PTE LTD Process/Location: Construction of Drywall Enclosure To OneNet Server at CLWP N6 Approved by: (Name, designation) (Date) Mr. Lee Wilson Senior Safety Manager 18 April 2011 1. Hazard Identification Jose Parrera/Boy C FDS Engineers 18 April 2011 Last Review Date: 18 April 2011 Next Review Date: 2d 3a 3b Action Officer Designation 2. Risk Evaluation 1a 1b 1c 1d 2a No Work Activity Hazard Existing Risk Control (if any) Site Preparation and Office Shifting Musculoskeletal – workers are at risk of strains, sprains and other muscle and tendon damage. Possible Accident/ Ill Health & Persons at Risk Workers disassembling partitions and moving them to temporary storage. Cuts and Lacerations when handling the partitions Workers disassembling and moving partitions Sight – Hand held power tools may be used to disassemble the partitions Hearing – Hand held power tools Workers performing this phase of the construction. 1 Conducted by: (Names, designations) (Date) EM 385-1-1 & Ministry of Manpower Requirements Workers performing this 2b 2c 01 November 2011 or when project is complete 3. Risk Control Severity Liklihood Risk Level Additional Risk Control Training on how to employ good lifting techniques and use the best work practices to avoid these types of injuries. This potential hazard should be discussed during musculoskeletal training All PNH Workers have been issued eye protection. Moderate Remote Low These risk evaluation ratings are assuming effective training is provided and consistently re-enforced for the workers. Safety Manager Minor Remote Low Ensure that a first aid kit is maintained on sight. Safety Manager Minor Remote Low Sight conservation training should be part of Tool Box Talks during this phase. Safety Manager All PNH Workers have been issued Minor Remote Low Hearing conservation training should be part of Tool Box Talks during this Safety Manager 2 Construct Drywall Enclosure for One-Net Server may be used to disassemble the partitions Musculoskeletal – workers are at risk of strains, sprains and other muscle and tendon damage Cuts and Lacerations when handling the partitions Sight – When installing the drywall there maybe sight risks when securing gypsum wall board, timber door and door frame and time. Hearing if hand held power tools are employed. 3 Painting - Apply one coat of wall sealer and two coats of interior paints Sight Paint Vapors phase of the construction. hearing protection. Workers handling/drywall may be at risk of strains, sprains and other muscle and tendon damage. Workers could be cut while assembling the dry walls. Training on how to employ good work practices to avoid these types of injuries. Minor Remote Low Ensure that good training is employed to ensure that workers do not sustain these types of injuries. Safety Manager This potential hazard should be discussed during musculoskeletal training All PNH Workers have been issued eye protection. Supervisors must enforce its use and this should be discussed during 10 minute tool box talks. All PNH Workers have been issued hearing protection. Minor Remote Low Ensure that a first aid kit is maintained on sight. Safety Manager Minor Remote Low PNH discusses Sight Conservation on a regular basis with workers but this safety aspect must be constantly reenforced. Safety Manager Minor Remote Low Hearing conservation training should be part of Tool Box Talks during this phase. Safety Manager Wear eye protection and cover this hazard in the morning 10 minute tool box talk as applicable The paint and wall sealer are not very toxic and are water based so they should not present a significant hazard, however, Minor Remote Low Project supervisors must enforce the use of eye protection. Safety Manager Minor Remote Low Respiratory protection should not be required because of the low toxicity of the paint and sealer. Safety Manager Workers performing this phase of the construction. Working with power tools during this phase of the construction. Workers applying the paint Workers applying paint and other people in the area. phase. 4 . Electrical Works Electric Shock – There will be significant work involving installation of new lighting and associated conduits, switches, etc. Personnel doing the electrical work. workers need to be cognizant of the fact that some people are more sensitive to these products than the general population which may make it necessary to move workers (other than the construction workers) outside of the area where painting is being conducted. Ensure that electrical components are tagged out. Never work on energized circuitry unless authorization is obtained from NAVFAC Far East. Minor Remote Low Contact Mr. Fred Bigcas from FDS Safety for all Lock Out/Tag Out issues. Safety Manager