DOC 326KB

advertisement

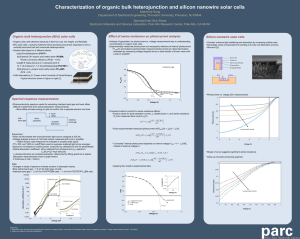

Lessons Learnt Report: Structured Junction Organic Solar Cells Project Name: New Materials and Architectures for Organic Solar Cells ‐ beyond the S‐Q limit Knowledge Category: Technical Knowledge Type: Technology Type: Technology Solar PV State/Territory: QLD Key learning Structured junction organic solar cells can have efficiencies higher than the equivalent planar devices. Implications for future projects The effect of structuring the active layer was demonstrated on small cells – active areas of 0.2 cm2. Application of the concept to larger areas was limited in this work by the fabrication method used for forming the silicon master stamp. Future projects in this area, particularly for scaling, will need to develop simple and cheap methods for producing the necessary stamps, and stamping methods compatible with active organic semiconductor layers. Background Objectives or project requirements The Shockley‐Queisser limit (SQ limit) is a thermodynamic limit to the conversion efficiency of a solar cell arising from the junction band gap (absorption overlap with the solar spectrum) and recombination effects, which act parasitically to reduce output current. The objective of our study was to use 2D or 3D structuring of the active layer to increase light harvesting efficiency through improved optical absorption and increasing the total junction surface area for charge separation/photon harvesting. Process undertaken Films of the 1:4 donor–acceptor blend of poly[N‐9′‐heptadecanyl‐2,7‐carbazole‐alt‐5,5‐(4′,7′‐di‐2‐ thienyl‐2′,1′,3′‐benzothiadiazole)] and methanofullerenephenyl‐C71‐ butyric‐acid‐methyl‐ester (PCDTBT:70‐PCBM) were structured using silicon moulds with identical diameter and pitches of 2 μm, 500 nm, and 100 nm. The pillar structures were patterned using electron beam lithography and the pillars were formed using the deep reactive ion etching (DRIE) technique to achieve a uniform 100 nm height. The devices were fabricated using the following process: 1) a 25–30 nm thin layer of poly(2,3‐dihydrothieno‐1,4 dioxin):poly(styrenesulfonate) was spin‐ coated onto an indium tin oxide coated glass substrates; 2) PCDTBT:70‐PCBM active layers were then deposited by spin‐coating with subsequent structuring by pressing the mould into the blend at 70 °C under inert conditions using a 1 [Insert Project Name] uniform force of between 0.5 and 1.0 N prior to the deposition of the top metal electrode. The 70 °C temperature allowed solvent evaporation out of the blend and at the same time ensured a good transfer of the mould structure; and finally 3) evaporation of a bilayer samarium/aluminium cathode. The devices were electrically characterized under an inert atmosphere without encapsulation. An NREL calibrated silicon solar cell with KG5 filter was used to calibrate the light intensity of the solar simulator to the AM1.5G standard of ~ 100mM /cm2. It was found that introducing structuring to the polymer–metal interface positively affects the device photocurrent resulting in a net gain of between 0.5–1.0 mA cm−2. The best planar devices produced a photocurrent density of 11.9 mA cm−2 with a power conversion efficiency of 6.4%. Whereas the best structured device produced a maximum photocurrent density of 12.6 mA cm−2 leading to efficiencies up to 6.8%. When compared to the best planar device, on average, we record a 4.5% increase in photocurrent in the 2 μm structured devices. The extra photocurrent contribution from the photoactive polymer‐fullerene blend was found to be clearly related to improved extraction of electrons at the organic–metal interface as well as improved light harvesting. This work was published in: “Nano‐structured, active organic‐metal junctions for highly efficient charge generation and extraction in polymer‐fullerene solar cells”, A.K. Pandey, M. Aljada, M. Velusamy, P. L. Burn & P. Meredith, Advanced Materials, 24, 1055‐1061 (2012). Supporting information Figure 1: The chemical structures of PCDTBT (left) and PC70BM (right). Figure 2 (a): Scanning Electron Microscopy (SEM) images of the silicon mould used for structuring the photoactive layer with the 2 μm pitch. (b) Atomic Force Microscopy tapping mode scans of structured active layer. 2 [Insert Project Name]