instructions to authors for the preparation - The Gibson Group

advertisement

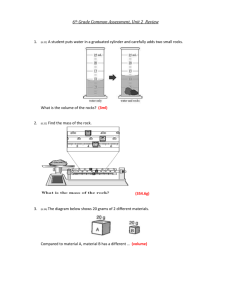

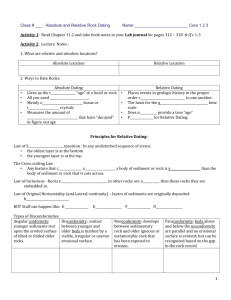

Hardness – a new method for characterising the interaction of disc-cutters and rocks? ABSTRACT One of the most important methods for material testing is the characterization of the hardness, which is defined as the resistance of a material to the penetration of another one (MARTENS & HEYN 1912). The methods according to Brinell (DIN EN ISO 6506), Vickers (DIN EN ISO 6507), Rockwell (DIN EN ISO 6508) and Knoop (DIN EN ISO 4545) are the most common and standardized ones for metal. As they are developed for predominantly ductile materials like steel, they can’t easily be applied to rocks which react much more plastic and brittle under indentation. But just as steel, rock is composed of different minerals and has a specific microstructure. Its mechanical parameters are connected with the particular grains, their cohesion and interlocking, just like steel. Figure 1 – a) Indentation of a Vickers-diamond with a load of 40.9 N (HV 5) in a sample of pure quartz (flint). Even with this load the long Palmquist-cracks and the lateral cracks around the indentation can be seen. b) SEM micrograph of a disc cutter. In the middle an indentation of a piece of a rock (darker part) which causes a strong deformation in the steel can be seen. Around, there are big and little scratches in various rights plus little indentations. The abrasivity of rocks and the accompanied wear of drilling tools today is mainly determined by simple and fast laboratory tests such as the Cerchar abrasivity test. Such laboratory tests are good tribological tests, but the Cerchar abrasivity test for example is limited mainly to rather weak rock types. This leads to an underestimation of abrasivity, e.g. in poorly lithified sandstones. As mentioned, hardness characterizes, depending on the type of deformation, predominantFigure 2 – Schematic illustration of the influence of microly plastic (metal) or elastic properties (rubstructural constituents of hardness. 1 = soft grain, 2 = hard ber) (HERRMANN et al. 2007). Rocks are in grain, 3 = indentor/test body, 4 = radius of the zone of influthe range between these two extremes. ence (after OETTEL & SCHUMANN (2011): 324). Since the rock drilling process, can be seen as a kind of penetration process on macroscopic and microscopic scales (compare figure 1), we picked up the idea to characterize the interaction of rock materials and TBM disc-cutters with hardness tests. In addition, this supports for a better understanding of the wear process on disc cutters. We used the hardnessdisparity concept after CARDU & GIRAUDI (2012) because wear can be understood as the interaction between the wear part and the material which causes the wear (tribological system). Several rock-forming minerals and some fine to coarse-grained monomineralic and polymineralic rocks were tested. In contrast to CARDU & GIRAUDI, we used the method after Vickers with loads up to 409.3 N (HV 50), depending on the estimated hardness to get bigger indentations and therefore as well information about the cohesion and interlocking of the minerals/grains. We also tested several associated disc cutters (Vickers test: HV 0.2, 200 g load, microhardness according to DIN EN ISO 6507). First results show that with higher loads (HV 5 - 50) and at least 10 indentations, we get a structural hardness in fine-grained rock samples (Figure 2), which permits a good characterization of the elasticity and brittleness, even on polymineralic rocks. Nevertheless, for the coarse-grained rock samples we need up to 40 indentations for a good characterization (in analogy of MANCHINI et al. 1993 and CARDU & GIRAUDI 2012). Using this method, a prediction of disc cutter wear is feasible taking into account the hardness of the disc cutter steel. In this paper, we would like to present this approved method in material sciences to derive an additional parameter for the characterization of rock abrasivity and wear. KEYWORDS Hardness, microhardness, Vickers, wear, abrasivity, disc cutters, rocks Authors: Peter Ellecosta, Heiko Käsling & Kurosch Thuro M.Sc. Peter Ellecosta, Chair of engineering geology, faculty of civil, geo and environmental engineering, Technische Universität München; p.ellecosta@tum.de Dr. Heiko Käsling, Chair of engineering geology, faculty of civil, geo and environmental engineering, Technische Universität München Prof. Dr. Kurosch Thuro, Chair of engineering geology, faculty of civil, geo and environmental engineering, Technische Universität München Literature: CARDU, M. & GIRAUDI, A. (2012): Metal-rock pair characterization in excavation engineering – The Journal of The Southern African Institute of Mining and Metallurgy, 112: 379-386; Johannesburg. HERRMANN, K., POLZIN, T., ULLNER, C. & WEHRSTEDT, A. (2007): Härteprüfung an Metallen und Kunststoffen – 251 S.; Renningen (Expert). MANCHINI, R., CARDU, M., FORNARO, M. & LINARES, M. (1993): Scale effects in the “micro-scale” rock mechanics problems – II International Workshop on Scale Effects in Rock Masses, 151-158; Lisbon. MARTENS, A. & HEYN, E. (1912): Handbuch der Materialkunde für den Maschinenbau – Bd. 1; Berlin (Springer).