Vickers Hardness Testing of Metallic and Ceramic Materials

advertisement

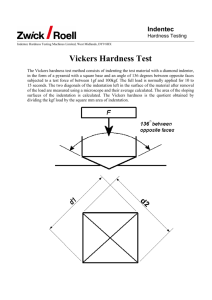

ebatco Exponential Business and Technologies Company Bridge You and Nano ______________________________________________________________________________ Vickers Hardness Testing of Metallic and Ceramic Materials The Vickers hardness test was developed in 1924 as a method for determining a material’s hardness regardless of an indenter’s size. It can be used for most materials, irrespective of hardness, and has one of the widest scales among hardness tests. The test is governed by ASTM standard E384 for loads ranging from 1 gf to 120 kgf. A typical Vickers hardness indentation can be seen in Figure 1. Figure 1. A typical Vickers hardness indentation in SS430. The Vickers hardness test is performed by pressing a diamond indenter tip in the form of a square-based pyramid into the sample at a specific load and then measuring the diagonal distances of the square indent that is created. The Vickers Hardness value, HV, is obtained via Equation 1, Eq. 1 HV 1.891F d2 where F is the indenting force in kgf and d is the average diagonal distance of the indentation in millimeters. The standard notation for reporting is HV followed by a number representing the indentation load in kgf. For example, 20 HV8 indicates a Vickers hardness value of 20 kgf/mm2 under a load of 8 kgf. Different indentation loads are selected depending on the thickness and volume of the sample that will be indented on. ______________________________________________________________________________ Address: 7154 Shady Oak Road, Minneapolis, MN 55344, U.S.A. Tel: +1 (952) 334-5486, Fax: +1 (952) 746-8086, Email: natlab@ebatco.com www.ebatco.com ebatco Exponential Business and Technologies Company Bridge You and Nano ______________________________________________________________________________ Vickers hardness testing is typically performed on samples that are too small or too thin to allow for testing using a different method. Stainless steel alloy 430 is frequently used as a thin protective liner for equipment used in moderately corrosive environments such as dishwashers, chemical processing equipment, heat exchangers, etc. As such, Vickers hardness testing is an appropriate method for testing SS430’s mechanical properties in many applications. Vickers hardness data for fully annealed SS430 obtained using a CSM Micro Indentation and Scratch Combi Tester (CSM Instruments, Switzerland) is given in Table 1. Table 1 Vickers Hardness Data for SS430 Test 1 2 3 4 5 Average S.D. HV1 (kgf/mm2) 166.82 163.74 161.39 161.56 161.48 163.00 2.35 Vickers hardness testing is also frequently used to characterize ceramic materials. Silicon nitride, Si3N4, is an engineering ceramic that is prized for its hardness, low coefficient of thermal expansion, superior wear resistance and corrosion resistance. Since there are several different methods of processing Si3N4, a Vickers hardness test can yield valuable information regarding how the material was processed and its resulting properties. Vickers hardness data for Si 3N4 obtained using a CSM Micro Indentation and Scratch Combi Tester is given in Table 2. Table 2 Vickers Hardness Data for Si3N4 Test 1 2 3 4 5 Average S.D. HV0.8 (kgf/mm2) 2189.97 2162.53 2305.83 2006.75 2040.34 2141.08 120.61 ______________________________________________________________________________ Address: 7154 Shady Oak Road, Minneapolis, MN 55344, U.S.A. Tel: +1 (952) 334-5486, Fax: +1 (952) 746-8086, Email: natlab@ebatco.com www.ebatco.com