ref 407c

advertisement

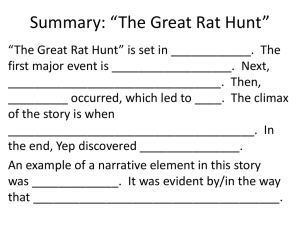

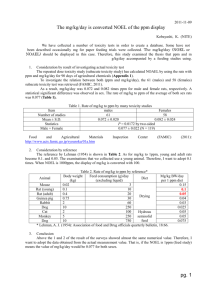

Refrigerant 407C Introduction: There is no general rule governing the selection of refrigerants. The best approach when presenting trends is certainly the per-application approach. Eight applications are examined: domestic refrigeration, commercial refrigeration, industrial refrigeration, land refrigerated transport, marine refrigerated transport, unitary air conditioning and heat pumps, water chillers, and mobile air conditioning. Global production of appliances reached 83 million in 1996, including 33 million in developing countries.1 The number of refrigeration appliances in the world is estimated at 1 billion, which represents 1 for 6 inhabitants. In France, the total is estimated at 37 million,2 which represents 1.7 appliances (refrigerator and/or freezer) per household, given that there are 21.9 million households in France.3 On refrigerated ships (reefers), besides R22, the main refrigerants used are R410A, R407C and R404A. In 1993, five refrigerated ships using ammonia were built. Since then, ammonia has no longer been used, except on fishing boats. Indirect systems using brines such as calcium chloride, and plate exchangers, are the most commonly used.4 However, refrigerated ships have been on the decline since the breakthrough of self-contained containers (in 1999, only 861 refrigerated ships with a capacity of over 100 000 cubic feet remained). On the other hand, the fleet of container ships is increasing proportionally, and nowadays there are more than 4000 such vessels.4 In terms of refrigerants, R22 is still used a lot in the US. Europe has moved towards R407C, probably because European regulations allowed insufficient time to develop drop-in equipment operating on R410A. In Japan, the policy is to use R410A. It is likely that R410A will dominate this sector in the future, especially for small capacities where energy efficiency is good, and because R410A is an almost azeotropic mixture. For medium capacities and capacities over 100 kW, R407C and R134a are undoubtedly used the most. Propane is used for portable equipment, but sales of portable equipment are decreasing in favour of benefit sales of split systems. CO2 is used in some heat pumps. We have to know that the R-407C is a blend refrigerant of HFC32, HFC125 and HFC-134a. It is a long life substitute of R22, harmless to Ozone. It is used in various of air conditioner, and non-centrifugal refrigeration system. TOXICOLOGICAL INFORMATION : IMMEDIATE (ACUTE) EFFECTS: HFC-32: LC50 : 4 hr. (rat) - 520,000 ppm / Cardiac Sensitization threshold (dog) 350,000 ppm HFC-125: LC50 : 4 hr. (rat) - > 800,000 ppm / Cardiac Sensitization threshold (dog) 75,000 ppm HFC-134a: LC50: 4 hr. (rat) - > 500,000 ppm / Cardiac Sensitization threshold (dog) > 80,000 ppm DELAYED (SUBCHRONIC AND CHRONIC) EFFECTS: HFC-32: Teratogenic NOEL (rat and rabbit) – 50,000 ppm Subchronic inhalation (rat) NOEL – 50,000 ppm HFC-125: Teratogenic NOEL (rat and rabbit) – 50,000 ppm Subchronic inhalation (rat) NOEL - > 50,000 ppm Chronic NOEL – 10,000 ppm HFC-134a: Teratogenic NOEL (rat and rabbit) – 40,000 ppm Subchronic inhalation (rat) NOEL – 50,000 ppm Chronic NOEL – 10,000 ppm Product Information : ASHRAE # Replaces Benefits Phaseout Schedule Lubricant Recommendation ASHRAE Safety Classification Cylinder Sizes R-407C R-22 Similar to R-22 in capacity and energy efficiency. Consult the specific regulations in your country or region POE A1 See specific container size information in your country or region. Typical Properties: Formula: CH2FJCHF2CF3/CF3CH2F Boiling Point (101.3KPa, ~C): -43.6 Freezing Point (~C): -Critical Temperature (~C): 87.3 Critical Pressure (KPa): 4820.0 Liquid Density (kg/m3): 1129.3 ODP: 0 GWP: 0.66 Pakage and Storage Cylinder with R-407C of 11.3 and 500kg. Filling coefficient is not more than 0.9kg/L. Retrofit of existing R-22 systems. However, 407C should not be used as a direct, "drop-in" replacement. Also, you should not use 407C in equipment that uses a flooded evaporator because of the zeotropic behaviour within the system. Definition of Terms Since 407C is a zeotropic blend, it helps to understand terms like bubble point, dew point, fractionation, and glide. o Dew point, or saturated vapor temperature, is the temperature where condensation begins (at constant pressure). Or, think of dew point as the temperature at which the last droplet of liquid evaporates and saturated gas exists. It corresponds to the condensation point of a single conponent refrigerant. o Bubble point and dew point are used to describe the behavior of zeotropic blends in an evaporator and condenser. Boiling point is not used because the blend's temperature changes as it evaporates or condenses. Bubble point, or saturated liquid temperature, is the temperature at which 407C (at constant pressure) begins to evaporate. Or in other words, the temperature where the first bubble of vapor appears in liquid Fractionation describes how a refrigerant blend like 407C changes from a liquid to a vapor or vice versa. Since the components of 407C evaporate (or condense) at different rates in the evaporator (or condenser), the blend's composition constantly changes between the bubble point (-46.12°F/-43.4°C) and dew point (-33.16°F/-36.2°C at one atm). Once the temperature exceeds the dew point, 407C is in a superheated vapor state. Glide describes the difference in temperature between the evaporator outlet and inlet due to fractionation. Glide can vary, depending on the state of the liquid refrigerant at either end of the evaporator (or condenser) or on pressure losses. At most common system pressures, 407C has a temperature glide of 9 to 12 degrees F. HAZARDS IDENTIFICATION: EMERGENCY OVERVIEW: Colorless, volatile liquid with ethereal and faint sweetish odor. Non-flammable material. Overexposure may cause dizziness and loss of concentration. At higher levels, CNS depression and cardiac arrhythmia may result from exposure. Vapors displace air and can cause asphyxiation in confined spaces. At higher temperatures, (>250°C), decomposition products may include Hydrofluoric Acid (HF) and carbonyl halides. POTENTIAL HEALTH HAZARDS: SKIN: Irritation would result from a defatting action on tissue. Liquid contact could cause frostbite. EYES: Liquid contact can cause severe irritation and frostbite. Mist may irritate. INHALATION: R-407C is low in acute toxicity in animals. When oxygen levels in air are reduced to 12-14% by displacement, symptoms of asphyxiation, loss of coordination, increased pulse rate and deeper respiration will occur. At high levels, cardiac arrhythmia may occur. INGESTION: Ingestion is unlikely because of the low boiling point of the material. Should it occur, discomfort in the gastrointestinal tract from rapid evaporation of the material and consequent evolution of gas would result. Some effects of inhalation and skin exposure would be expected. DELAYED EFFECTS: None known. FIRST AID MEASURES SKIN: Promptly flush skin with water until all chemical is removed. If there is evidence of frostbite, bathe (do not rub) with lukewarm (not hot) water. If water is not available, cover with a clean, soft cloth or similar covering. Get medical attention if symptoms persist. EYES: Immediately flush eyes with large amounts of water for at least 15 minutes (in case of frostbite water should be lukewarm, not hot) lifting eyelids occasionally to facilitate irrigation. Get medical attention if symptoms persist. INHALATION: Immediately remove to fresh air. If breathing has stopped, give artificial respiration. Use oxygen as required, provided a qualified operator is available. Get medical attention. Do not give epinephrine (adrenaline). INGESTION: Ingestion is unlikely because of the physical properties and is not expected to be hazardous. Do not induce vomiting unless instructed to do so by a physician. ADVICE TO PHYSICIAN: Because of the possible disturbances of cardiac rhythm, catecholamine drugs, such as epinephrine, should be used with special caution and only in situations of emergency life support. Treatment of HANDLING AND STORAGE NORMAL HANDLING: (Always wear recommended personal protective equipment.) Avoid breathing vapors and liquid contact with eyes, skin or clothing. Do not puncture or drop cylinders, expose them to open flame or excessive heat. Use authorized cylinders only. Follow standard safety precautions for handling and use of compressed gas cylinders. R-407C should not be mixed with air above atmospheric pressure for leak testing or any other purpose. STORAGE RECOMMENDATIONS: Store in a cool, well-ventilated area of low fire risk and out of direct sunlight. Protect cylinder and its fittings from physical damage. Storage in subsurface locations should be avoided. Close valve tightly after use and when empty STABILITY AND REACTIVITY NORMALLY STABLE? (CONDITIONS TO AVOID): The product is stable. Do not mix with oxygen or air above atmospheric pressure. Any source of high temperature, such as lighted cigarettes, flames, hot spots or welding may yield toxic and/or corrosive decomposition products. INCOMPATIBILITIES: (Under specific conditions: e.g. very high temperatures and/or appropriate pressures) – Freshly abraded aluminum surfaces (may cause strong exothermic reaction). Chemically active metals: potassium, calcium, powdered aluminum, magnesium and zinc. HAZARDOUS DECOMPOSITION PRODUCTS: Halogens, halogen acids and possibly carbonyl halides. HAZARDOUS POLYMERIZATION: Will not occur. Applications - Positive displacement equipment: o new or existing residential and commercial air-conditioners o new or existing residential and commercial heat pumps - conditioning applications. They include: New residential and other unitary air conditioning, non-flooded evaporator chillers. With few modifications, 407C can be used in the same equipment designed for use with R-22 - Existing medium-temperature applications. R407C used in air conditioning seems more likely to be used on a short-term than on a long-term basis. * We will take a company with it manufacture this type of refrigerants today to be close for the real information and took about it's properties, charts, curves….etc, from it's catalogs. We will take the Suva® 407C Refrigerant: References: 1. UNEP. 1998. 1998 Report of the Refrigeration, Air Conditioning and Heat Pumps Technical Options Committee, Nairobi, UNEP, 285 pages. 2. AFF. 2001. Conseil National du Froid – Livre blanc sur les fluides frigorigènes, Paris, AFF, 51 pages. 3. Quid. 1999. 4. Stera A.C. 1999. Long Distance Refrigerated Transport Into the Third Millennium, 20 International Congress of Refrigeration, IIF/IIR, CD-ROM. 5. http://refrigerants.dupont.com/Suva/en_US/products/suva407c.html 6. http://www.refrigerants.com/msds/r407c.pdf 7. http://www.arkema-inc.com/index.cfm?pag=34 th