View

advertisement

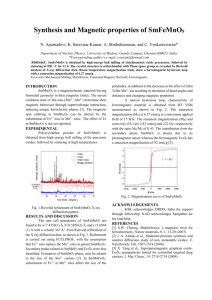

Effect of Cr substitution on CoFe2O4 nanoparticles M. Vadivel, R. Ramesh Babu* Crystal Growth and Thin Film Laboratory, Department of Physics, Bharathidasan University, Tiruchirappalli 620 024, Tamil Nadu, India * Corresponding Author’s Email: rampap2k@yahoo.co.in Tel: + 91-431-2407057 Fax: + 91-431-2407045 Abstract TEM analysis Formation of single phase cubic spinel structure was confirmed by XRD. TEM observations revealed that the CoFe2O4 and CoFe2-xCrxO4 nanoparticles are uniformly distributed and not highly agglomerated. Magnetic properties revealed that the saturation magnetization of the samples decreases with increasing Cr concentration and lie in the range of 69.67- 42.71 emu/g for the prepared samples. TEM analysis reveals that the prepared nanoparticles shows regular in shape. Also the average particle size increases with increasing the Cr concentration up to x = 0.2 concentration, thereafter decreases when compared with pure CoFe2O4 nanoparticles. Keywords: Nanoparticle; Chemical synthesis; diffraction; Dielectric Property; Magnetic Property Dielectric study reveals that the dielectric constant and dielectric loss of the prepared nanoparticles increases with increase in temperature whereas both are decreases with increasing frequency. Cobalt ferrite is one of the fascinating magnetic materials since it possesses strong magnetic anisotropy, high coercivity at room temperature (5400 Oe), moderate saturation magnetization (80 emu/g) and good mechanical and chemical stabilities [1]. In spinel ferrites, addition of metal cations of different valance states leads to variety of tetrahedral (A) and octahedral (B) sites distribution [2]. In the present investigation, pure and Cr substituted CoFe2O4 magnetic nanoparticles were prepared by coprecipitation method for various concentration of Cr and the effect of Cr concentration on the structural, spectral, dielectric, magnetic and optical properties is reported in the present work. Synthesis Cr substituted CoFe2O4 nanoparticles, CoFe2-xCrxO4 (x = 0.0, 0.1, 0.2 and 0.3), were prepared by co-precipitation method using high purity iron (III) chloride hexahydrate, cobalt (II) chloride hexahydrate and chromium (III) chloride hexahydrate. Magnetic properties Magnetic measurements show that the saturation magnetization, retentivity and magneton number decreases with increasing Cr concentration which may be due to the weakening of superexchange interaction between the tetrahedral A site and octahedral B site in the ferrites. 80 60 40 CoFe2O4 CoFe1.9Cr0.1O4 CoFe1.8Cr0.2O4 CoFe1.7Cr0.3O4 20 0 Ms 70 -20 Saturation Magnetization (emu/g) Introduction Dielectric properties Magnetization (emu/g) X-ray -40 -60 60 55 50 45 40 -80 -20000 65 0.00 -15000 -10000 -5000 0 5000 0.05 0.10 0.15 0.20 Cr concentration 10000 0.25 15000 0.30 20000 Magnetic Field (Oe) Results and discussion X-ray diffraction analysis XRD peaks reveal that the prepared samples belong to a single phase cubic spinel structure. The crystallite size varies from 15 to 23 nm. Lattice constant slightly increases for x = 0.1 and thereafter it decreases gradually from the value of CoFe2O4. The variation in lattice constant may be attributed to the replacement of Fe3+ ions (ionic radius 0.64 Å) by relatively smaller ionic radius (0.63 Å) Cr3+ ions. The porosity of the synthesized samples decreases with increasing Cr concentration. Fig.1 Magnetic hysteresis loops of CoFe2-xCrxO4 nanoparticles at room temperature (inset) The variation in saturation magnetization (Ms) with different Cr concentrations Acknowledgement One of the authors MV is thankful to UGC-BSR, Govt. of India for the award of ‘Research Fellowship in Science for Meritorious Students-2013’. The authors are thankful to Dr. M. Arivanandhan for TEM analysis. References FTIR spectral analysis The symmetric stretching vibration of Fe-O (metaloxygen) band at the tetrahedral site is observed at 587 cm-1. [1] Y. Qu, H. Yang, N. Yang, Y. Fan, H. Zhu, G. Zou, Mater. Lett. 60 (2006) 3548. [2] S. Singhal, S. Jauhar, J. Singh, K. Chandra, S. Bansal, J. Mol. Struct. 1012 (2012) 182.