Marine Boilers Steam and Water

advertisement

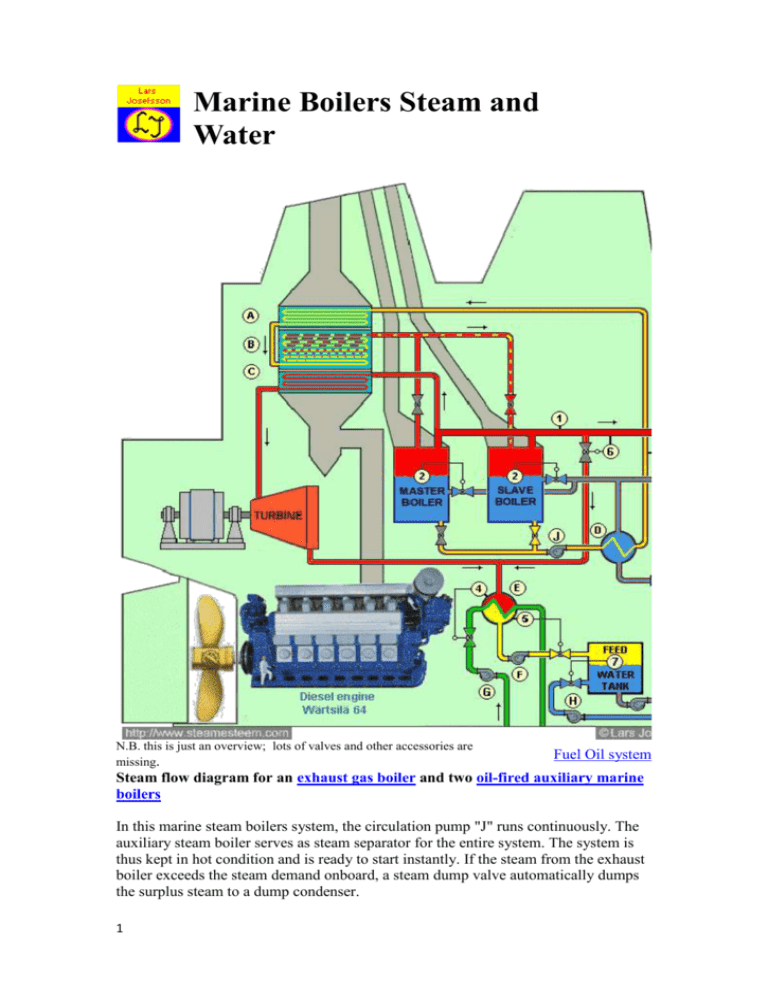

Marine Boilers Steam and Water N.B. this is just an overview; lots of valves and other accessories are missing. Fuel Oil system Steam flow diagram for an exhaust gas boiler and two oil-fired auxiliary marine boilers In this marine steam boilers system, the circulation pump "J" runs continuously. The auxiliary steam boiler serves as steam separator for the entire system. The system is thus kept in hot condition and is ready to start instantly. If the steam from the exhaust boiler exceeds the steam demand onboard, a steam dump valve automatically dumps the surplus steam to a dump condenser. 1 The energy content of the exhaust gases is utilized optimally in this marine boiler system. In addition to generating superheated steam for driving a turbo-alternator, the exhaust gas boiler also supplies steam for other requirements on board. Some things to think about The outside temperature of the tubes of an Exhaust Gas Economizer of forced circulation type, the most common type today, is only a few °C higher than the water inside the tubes. The water temperature must therefore not be below 130°C if low temperature corrosion shall be avoided. Since ships mostly are equipped with open feed water systems where the feed water temperature is not higher than 50-80°C this feed water may be mixed with saturated water from the Oil Fired Boiler or from a steam separator drum, in proportions so that the water entering the EGE is minimum 130°C. As the feed water from the open feed water system contains oxygen, installation of a de-airator in this case is ecommended in order to avoid oxygen corrosion inside the tubes. However, the most common way is to feed the EGE with saturated water from the OFB linked with EGE, since the temperature of the saturated water entering the EGE is reduced to 130°C in an externas heat changer by the feed water having a temperature of 50-80°C. If the steam is used for production of electric energy by a turbo alternator, a superheater may be incorporated and located on the gas inlet side of the EGE. Except for tankers that mostly are provided with large OFB's producing steam for the cargo pumps, the main part of the operating ships are furnished with an OFB and an EGE with capacities which are generally large enough to maintain only the bunker heating and the domestic heating. However, where there are energy enough in the exhaust gases, it should be economically justified to instalI a turbo-alternator set. When the EGB then is designed for a high rate of heat recovery from the gases, the EGB wilI be larger in size and it wilI thus have a larger water volume inside the tubes. Due to increased steam production and water volume of the EGE, the OFB, steam receiver, has to be enlarged in order to obtain larger steam space and to withstand level variations which occur when the main engine starts and stops. When the main engine starts, and consequently the steam production takes place, the water in the EGB will expand and will be pressed from the EGE to the OFB where the water leivel increases. On the contrary, when the main engine stops, the steam production interrupts. The circulating water pump will then fill up the EGE with water that results in a decrease of the water level in the OFB. In case of a too small OFB compared with the steam production and the water content of the EGE, the water level variations in the OFB will be unacceptable and they will cause repeated, undesired high and low level alarms. A. Economizer section of the Waste Heat Recovery Boiler Preheats the circulating water before it enters the evaporator tubes. The counterflow principle is applied, i.e., the hottest exhaust gasses meet the heated feed water. B. Evaporator section of the Waste Heat Recovery Boiler Water evaporates and emulsion of steam and water flows back to the boiler. The counterflow principle is not applied since the evaporated steam rises in 2 C. D. E. F. G. H. I. J. K. the tube bank and it would be disadvantageous to let the steam rise against the water flow. Superheater section of the Waste Heat Recovery Boiler Superheats the steam for the turbine. The counterflow principle is applied, i.e., the hottest exhaust gasses meet the superheated steam. Heat exchanger Preheats the boiler feedwater. Condenser The exhaust steam from the turbine and excess steam from the steam system condense and recycle. Condensate pump Cooling water pump Seawater. Make-up water pump From softener unit. Boiler feedwater pump Boiler water circulation pump Alternator Deliver electric power to the ships different el-consumers. 1. Steam pressure control The pressure control loop adjusts the burner load according the steam demand. 2. Water level control A simple control loop will do for a boiler with large amount of water and relatively small steam output. To minimize shrink and swell at start and stop of the burner it would be wise to have two setpoints for the water level. A lower level (abt. 40%) when the burner is stop and a higher (abt. 50%) when it's firing. 3. Economizer inlet temperature control The feedwater is pre-heated in order to increase the efficiency of the plant. The circulating water to the exhaust gas boiler heats the feed water and the three-way valve on the inlet to the heat-exchanger controls the temperature. The economizer inlet temperature must never fall below 135°C to avoid corrosion on the economizer tubes. 4. Condenser pressure control An absolute pressure transmitter and a controller adjust the cooling-water to the condenser to protect the condensate from being cooled down more than necessary. 5. Condenser level control The level controller actuates the condensate outlet control valve. 6. Steam dump control valve Takes care of excess steam from the waste heat boiler when the steam production exceeds the steam demand. 7. Feedwater tank level control The level controller actuates the make up water control valve. 3|Page 3