Materials All chemicals have been purchased from Sigma

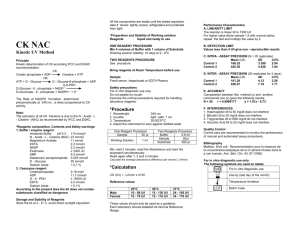

advertisement

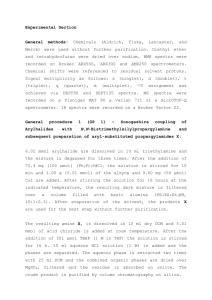

Materials All chemicals have been purchased from Sigma-Aldrich, unless otherwise noted. All spectroscopic data was measured on a Bruker 400 MHz NMR spectrometer. Reactions were monitored by thin layer chromatography on 0.25 mm Dynamic Adsorbents, L.L.C pre-coated silica gel. All reagents were distilled prior to use. Flash chromatography was performed using Whatman Purasil 60 Ǻ (230-400 mesh ASTM) silica gel. Microwave reactions were carried out in a capped vial on CEM Discover System. 1. Synthesis of d-galactofuranose motif via one-pot procedure 3.3 g of D-galactofuranose (18.3 mmol) was dissolved in pyridine (10 mL) and allyllic alcohol (6.4 mL, 73.9 mmol). The D-Galf mixture was cannule added to a 250-mL round bottom flask containing NaH (1.05 g, 27 mmol) and the reaction was allowed to stir at -70 C for 72 hours. Progress was monitored often by TLC, and the reaction was allowed to continue to stir until completion was evident. 2. Synthesis of 2-acetamido-4-amino-L-fucose motif via one-pot procedure 3.3 g of 2-acetamido-D-glucopyranose hydrochloride (13.91mmol) was dissolved in cold pyridine (10 mL) and oxidized to the corresponding 2-azido-4-amino-D-glucopyranose by first adding imidazole-1sulfonyl azide hydrochloride (3.51g, 33.62 mmol) for 23 hours, then adding acetic anhydride at room temperature and letting the mixture react overnight. The desired compound was isolated by rotary evaporation followed by acid-base extraction, bringing the pH below 3.0. The precipitate was separated from the mother liquor by decantation. The solid was then dissolved in cold CH2Cl2 (10 mL) and then converted to the thio-glycoside by addition of BF3-OEt2 (3.03 mL,24.12 mmol) and thiophenol (1.67 mL, 16.08 mmol) at 0 C for 24 hours. Deprotection and selective C-6 reprotection was performed by addition of excess MeOH/NaOMe at 0 C, followed by addition of TsCl (0.80 g, 4.12 mmol). The mixture was isolated by flash chromatography. The pure 6-protected product was dissolved in hexamethylphosphoramide, HMPA (40 mL), and added to a microwave vessel, along with CNCH3 (5 mL), NaI (0.50 g, 3.32 mmol), and NaCNBH3 (1.70 g, 26.60 mmol). The microwave vessel was run at 400 MHz for 6 hours and then removed. The vessel was shaken vigorously, reattached to the microwave and run at the same conditions. This was followed twice more. The product was isolated by flash chromatography. 3. Synthesis of 4,6-Pyruvate Acetal-2,3-Dibenzoyl-D-Galactopyranoside motif Acetic anhydride (13.15 mL, 139.10 mmol) was added to 2 g of D-galactopyranose previously dissolved in cold pyridine (10 mL) and the mixture was allowed to stir for 20 hours at 0 C to room temperature. The totally protected sugar was then treated with BF3-OEt2 (4.59 mL, 36.50 mmol) and thiophenol (2.82 mL, 27.88mmol) and purified by flash chromatography. Deprotection was performed by addition of excess MeOH/NaOMe, and the totally unprotected sugar was isolated by acid-base extraction (pH <3). The precipitate was then dissolved in dry DMF (15 mL) and to it, p-methoxyphenyl a,a-dimethoxy benzaldehyde (0.12 mL, 0.89 mmol) was added, along with p-TsOH (20 mL) to produce the 4,6-benzylidine acetal derivative. The product was dried in vacuo , dissolved in dry pyridine (15mL) and protected with benzoyl chloride, BzCl (0.11 mL, 0.774 mmol). DDQ (1.42g, 6.26 mmol) was added, along with CH3CN:H2O (10:1, 15 mL) to reduce C-4 and C-6 back to their respective alcohols. The product was then placed in a microwave vessel and to it, H2O and methyl pyruvate (51 microL, 0.492 mmol) was added. It was run for 90 minutes at 400 MHz to produce the 4,6-pyruvate acetal. The product was isolated by flash chromatography. 4. Synthesis of 2-acetamido-D-galactopyranoside motif via one-pot procedure 3.30 g of 2-amino-D-galactopyranose (13.92 mmol) was added to acetic anhydride (10.15 mL, 110 mmol) in dry pyridine (15 mL) and cooled to -30 C. The mixture was then separated by acid-base precipitation, by lowering the pH below 3.0 and isolating the precipitate from the mother liquid by decantation. The solid peracetylated compound was dissolved in cold water and converted to the corresponding thio-glycoside by adding BF3-OEt2 (3.03 mL, 24.12 mmol) and thiophenol, PhSH (1.67 mL, 16.07 mmol) . The mixture was placed into a pressure sealed microwave vessel and run for 6 hours at 300 MHz. The product was deprotected by work-up, using excess amounts of cold methanol/sodium methoxide to yield a totally unprotected 2-acetamido-D-galactopyranose thioglycoside. Conversion to the 4,6-benzylidine acetal was performed by employing a,a-dimethoxybenzaldehyde (0.168 mL, 1.11 mmol) solvated in DMF (1.5 mL) and drying by rotary evaporation. It was then purified by flash chromatography. Coupling of Monosaccharide units 1,2,3,4 Monosaccharides 2, 3, and 4 were converted to their corresponding 2-trichloro acetamidate derivatives by dissolving each in CH2Cl2 and adding CCl3CN (0.048 mL, 0.48 mmol) and excess DBU. Each was purified by flash chromatography. 3 and 4 were coupled by adding each solid to a single microwave vessel, dissolving in DMPU (5 mL) and irradiating for 6 hours at 300 MHz. Purity was verified by 1H NMR and 2D-1HMQCOSY. The disaccharide was dissolved in DMPU (5 mL) and added to a microwave vessel.2 was added and the vessel was irradiated at 400 MHz for 5 hours. The trisaccharide was purified by flash chromatography and then returned to the microwave vessel. DMPU (5 mL) was added and finally, 1 was added. The mixture was irradiated at 100 MHz for 60 minutes and the tetrasaccharide was purified by flash chromatography. Purity was determined by HR-MS, 1H NMR, 13C NMR, 2D-NMR and IR spectroscopy. Coupling of 2 and 3, followed by the addition of 1 and 4 was attempted, with unsuccessful results. Other approaches have been proposed by our group, and future attempts are expected.