Aquapure Troubleshooting part 3: Common upsets - Hubbard-Hall

advertisement

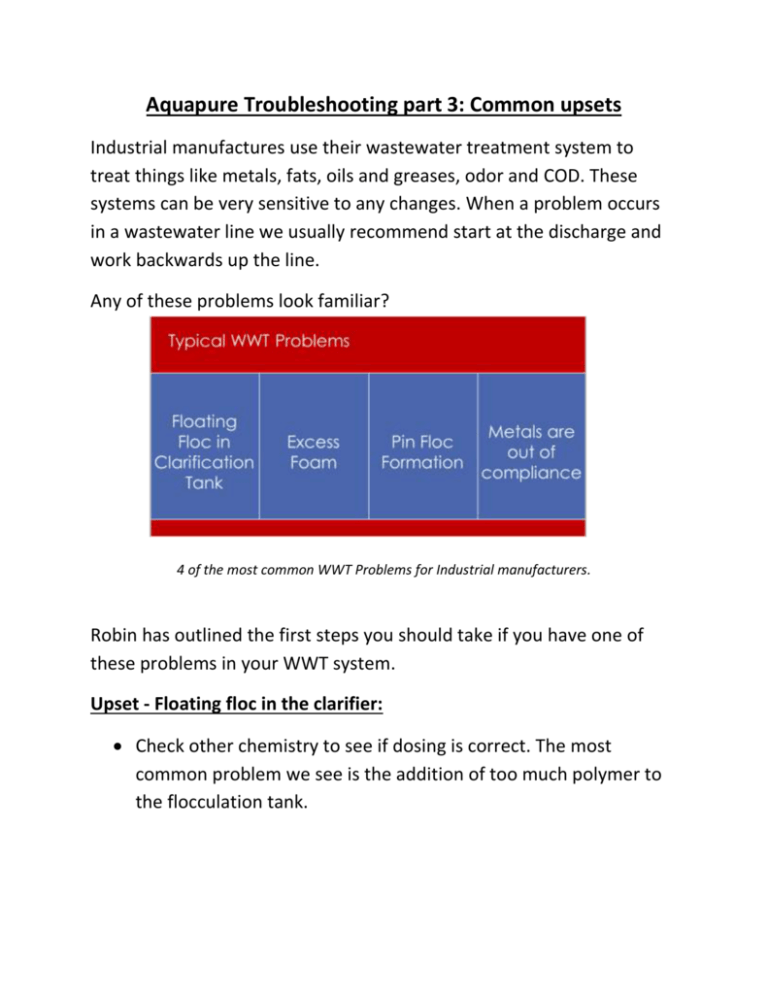

Aquapure Troubleshooting part 3: Common upsets Industrial manufactures use their wastewater treatment system to treat things like metals, fats, oils and greases, odor and COD. These systems can be very sensitive to any changes. When a problem occurs in a wastewater line we usually recommend start at the discharge and work backwards up the line. Any of these problems look familiar? 4 of the most common WWT Problems for Industrial manufacturers. Robin has outlined the first steps you should take if you have one of these problems in your WWT system. Upset - Floating floc in the clarifier: Check other chemistry to see if dosing is correct. The most common problem we see is the addition of too much polymer to the flocculation tank. Check the pH and ORP of the water in the clarifier. If the ORP is positive- possible residual oxidizer needs to be reduced. Air from solids on the bottom could be growing bacteria and off-gassing, latching onto particles. Correction would be to blowdown the clarifier and add a small amount of defoamer to the clarifier or the premix tank. Check if the flow rate has increased. If it has, it could be due to increased production not giving enough time for the settling of solids. Upset - Foam Check for any air lines bringing air into the system. Is there any bacterial growth? Excess foam can begin by growth of bacteria from colloidal solids in slow moving rinses that let off gas and rise to the surface leading to foam and odor. Check with production for dumps. For example if there is a cleaner dump (instead of a bleed and feed) into a continuous flow type system the higher concentration combined with the agitation can create a lot of foam. If foam is left untreated it can increase and lead to inaccurate level indicators in tanks creating false calls for water or chemistry. It can also grow so much that it escapes the tank- overflowing on the floor causing unsafe, slippery conditions. Upset - Pin floc formation: Check the lines and pumps to the polymer drum and make sure lines are not clogged. Polymers have a shelf life once water has been added. The harder the water - the shorter the shelf life. Anionics last 1 month, cationics last 1-2 days. Was the polymer “made down” correctly? If there is residual diluted polymer left in the day tank- the concentrate amount has to be adjusted down so as not to include this in the calculation. The polymer needs to mix until homogenous then the mixer should be turned off and allowed to age for 30 minutes-1 hour for best activity. The mixer in the premix tank should be slow with large paddles so as not to shear the floc. Do some jar testing on the line to see if the water coming into the system has enough contaminants to treat. If there is way less metals then the treatment becomes more difficult or the coagulant has to be boosted. Are you using the right polymer? There are many to choose from through bench testing with your chemical provider. They will be anionic, cationic or non-ionic. Upset - Metals out of Compliance: Check the pH and ORP in the clarifier water. It should be around 8.5-9.5. If it is out of this range check your solubility chart to make sure you are in the right pH range. Go back to the EQ tank and check the lines and dosing of the coagulant. Make sure the drums are also pumping properly. Then do some benchside jar testing by bracketing the dosing of the coagulant – if you normally dose a 1 ml/gal then try ½ ml and 2-3 ml so you can see what an increase or decrease in chemistry helps. Check with production on spent bath dumps or cleanouts, new chemistry used and new jobs coming in. If a new metal shows up find out why and the pH at which it is least soluble. If there a new cleaner on the line that possibly has a chelator in it. You may have use a metal precipitant in this case.