bit25867-sup-0001-SuppData

advertisement

1

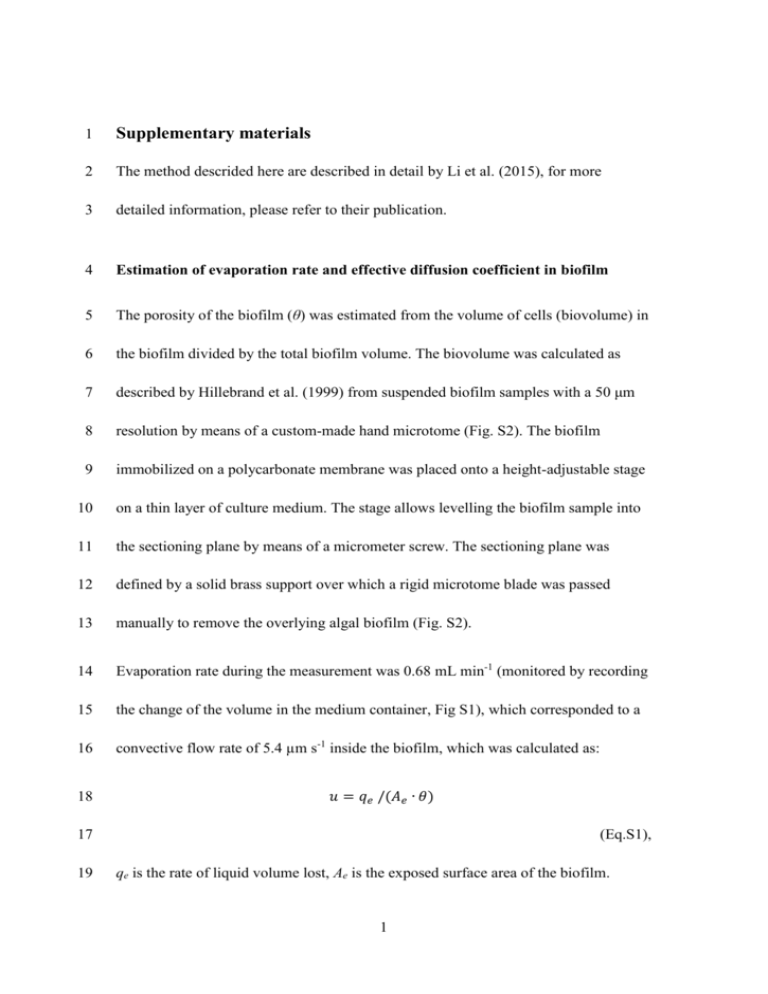

Supplementary materials

2

The method descrided here are described in detail by Li et al. (2015), for more

3

detailed information, please refer to their publication.

4

Estimation of evaporation rate and effective diffusion coefficient in biofilm

5

The porosity of the biofilm (θ) was estimated from the volume of cells (biovolume) in

6

the biofilm divided by the total biofilm volume. The biovolume was calculated as

7

described by Hillebrand et al. (1999) from suspended biofilm samples with a 50 μm

8

resolution by means of a custom-made hand microtome (Fig. S2). The biofilm

9

immobilized on a polycarbonate membrane was placed onto a height-adjustable stage

10

on a thin layer of culture medium. The stage allows levelling the biofilm sample into

11

the sectioning plane by means of a micrometer screw. The sectioning plane was

12

defined by a solid brass support over which a rigid microtome blade was passed

13

manually to remove the overlying algal biofilm (Fig. S2).

14

Evaporation rate during the measurement was 0.68 mL min-1 (monitored by recording

15

the change of the volume in the medium container, Fig S1), which corresponded to a

16

convective flow rate of 5.4 µm s-1 inside the biofilm, which was calculated as:

18

𝑢 = 𝑞𝑒 /(𝐴𝑒 ∙ 𝜃)

17

19

(Eq.S1),

qe is the rate of liquid volume lost, Ae is the exposed surface area of the biofilm.

1

20

Microsensor setup

21

A schematic representation of the experimental setup for microsensor measurements

22

based on previous works by Gieseke and de Beer (2004) is given in Fig. S1: the

23

biofilm immobilized on a polycarbonate membrane was placed onto a moist glass

24

fiber inside the biofilm measurement cell under a controlled atmosphere of

25

compressed air at a flow rate of 1 L min-1 (Fig. S1A). The non-inoculated area of the

26

polycarbonate filter and glass fiber were covered with a black plastic foil to exclude

27

light and gas exchange in this area. 50 mL of BBM culture medium were circulated

28

though the measurement cell with a flow rate of 3 mL min-1 by means of a peristaltic

29

pump and were exchanged every 1 hour during the measurement. Light was supplied

30

from the front side by a halogen lamp (KL-1500, Schott, Mainz, Germany) equipped

31

with a 3-fold splitter to ensure even distribution. The movement of the sensor was

32

enabled by a computer-controlled micromanipulator (Pollux Drive, PI miCos,

33

Eschbach, Germany). Microsensor signals were amplified and converted into digital

34

data (DAQpad 6015 and 6009, National Instruments, Munich, Germany) prior to their

35

further processing on a computer (Fig. S1B). Software used for system control and

36

data acquisition was custom made (can be acquired upon request from Dr. Lubos

37

Polerecky, Utrecht University, Netherlands, l.polerecky@uu.nl). Light-dark shift

38

measurements (Revsbech, 1989) were carried out, and the data acquired was

39

processed as described in the following section. Linear calibration of oxygen

40

microsensor was carried out as described by Revsbech (1983) using BBM medium

2

41

saturated with nitrogen gas or compressed air. A shutter connected to a timer was

42

used to control light-dark cycling: the total dark period was 3 s, and a linear

43

regression slope of oxygen concentration change between 0.7 and 2.1 s of the dark

44

period was determined as the measured value. For each measurement depth, three

45

light-dark cycles were performed after steady state was reached (this could be as long

46

as 10 min), and these 3 values acquired were considered as triplicates. The PAR light

47

intensity of a fixed depth was determined as the average value of a 3 s measurement

48

period.

49

Gross photosynthetic productivity calculation

50

Take the derivative of time on both sides of the dissolved oxygen mass transfer

51

equation, and assume the time t and spatial variables x are not dependent (as during

52

the measurement period, the thickness of the biofilm hardly changes) (Bergman et al.,

53

2011, Revsbech and Jorgensen, 1983):

55

𝜕𝐶

𝜕𝐶

𝜕2 ( )

𝜕( )

𝜕𝐶

𝜕𝑡 + 𝑢

𝜕𝑡 − 𝜕𝑅 /𝜕𝑡

𝜕( )/𝜕𝑡 = 0/𝜕𝑡 − 𝜕𝑅𝑙 /𝜕𝑡 + 𝐷𝑒

𝑠

𝜕𝑡

𝜕𝑥 2

𝜕𝑥

54

(Eq.S2).

56

The term ∂Rs/∂t represents the rate change of the removal of dissolved gaseous

57

species at the submerged biofilm surface due to the flow of bulk liquid, or, in this

58

case, of the gas phase above the biofilm:

59

𝜕𝑅𝑠 /𝜕𝑡 = (𝐷𝑒

(𝐶 − 𝐶𝑠 )

(𝐶 − 𝐶𝑠 )

+

𝑢

)/𝜕𝑡

𝑥2

𝑥

3

=(

61

𝐷𝑒 𝑢

+ ) ∙ 𝜕𝐶/𝜕𝑡

𝑥2 𝑥

60

(Eq.S3).

62

Cs represents the oxygen concentration on the very surface of the aerial biofilm,

63

which is in equilibrium with the phase above and is considered to be a constant.

64

Considering that the rate of respiration remains stable during the measurement period

65

(Glud et al., 1992), and take ∂C/∂t=P(x, t), as ∂C/∂t is a function of depth x and time t.

66

Substitute Eq.S3 into ∂Rs/∂t and ∂C/∂t to P(x, t), Eq.S2 becomes:

68

𝜕 2 (𝑃(𝑥, 𝑡))

𝜕(𝑃(𝑥, 𝑡))

𝜕𝑃(𝑥, 𝑡)

𝐷𝑒 𝑢

= 0 − 0 + 𝐷𝑒

+𝑢

− ( 2 + ) ∙ 𝑃(𝑥, 𝑡)

2

𝜕𝑡

𝜕𝑥

𝜕𝑥

𝑥

𝑥

67

(Eq.S4).

69

Eq.S4 is a nonhomogeneous diffusion equation with a sink and can be solved by using

70

any of the methods summarized by Crank or Polyanin (Crank, 1975; Polyanin, 2002).

71

Using an initial condition P(x, t = 0) = P(x, 0) and a boundary condition ∂P(x = 0,

72

t)/∂t = 0, the exact solution of Eq.S4 at t = τ can be expressed as:

𝛿

74

𝑃(𝑥, 𝜏) = ∫ 𝑃(𝑦, 0) ∙ [𝑒

−(𝑦−𝑥+𝑢∙𝜏)

(

)

4∙𝐷𝑒 ∙𝜏

0

−𝑒

−(𝑦+𝑢∙𝜏)

(

)

4∙𝐷𝑒 ∙𝜏

∙ 𝑒𝑟𝑓𝑐(

𝑥

√4 ∙ 𝐷𝑒 ∙ 𝜏

)] ∙ 𝑑𝑦

73

(Eq.S5),

75

δ is the total depth of the biofilm, or, alternatively, the depth until which the shift from

76

light to dark has an effect on the dissolved oxygen concentration. P(x, τ) is the

77

measured value from the light-dark shift method with measurement time τ at

78

measurement depth x, and P(y, 0) is the actual photosynthetic activity at position y

4

79

(the integrating variable), which is the desired term. For measurements taken at all

80

depths, the measured value P(x, τ) at a depth x depends on the P(y, 0) across the

81

complete photosynthetically active region of the biofilm (surface to depth δ).

82

Eq.S5 is a Fredholm integral equation of the first kind (Kress, 2014), and its

83

approximated solution can be calculated using Tikhonov regularization (Tikhonov et

84

al., 1995) with a non-negative constrain applying the active-set algorithm purposed by

85

Gill et al. (1981): Discrete δ by n, and let P(xj, τ) = gj, P(yi, 0) = hi; (i, j = 1, 2, …, n)

86

and write Eq.S5 in the discrete operator notion.

𝑛

𝑔𝑗 = ∑ 𝑘𝑖,𝑗 ∙ ℎ𝑖

88

𝑖

87

(Eq.S6),

89

ki,j is the operator term which contains both the term that reflects the effect of

90

diffusion and advection of dissolved oxygen inside the biofilm (inner term, first term

91

in square bracket in Eq.S5) and the term that reflects the effect of dissolved oxygen

92

removal due to surface flow (surface term, second term in square bracket in Eq.S5). In

93

matrix notion, let G be a vector containing gj, H a vector containing hi, and K a matrix

94

containing the operator terms ki,j:

𝐺 =𝐾∙𝐻

96

95

97

(Eq. S7).

Rewrite Eq.S7 as:

5

(𝐺𝑖𝑛 + 𝐺𝑠𝑢𝑟𝑓 ) = (𝐾𝑖𝑛 + 𝐾𝑠𝑢𝑟𝑓 ) ∙ 𝐻

99

98

(Eq.S9),

100

The subscripts in and surf represent the effect from the inner term and the surface

101

term in Eq.S5 respectively, operators Kin, Ksurf can be calculated using Eq.S5, as well

102

as gin and Gsurf, if an H is given. Apply the Tikhonov regularization, the problem in

103

Eq.11 thus becomes:

2

min {‖(𝐺𝑖𝑛 + 𝐺𝑠𝑢𝑟𝑓 ) − (𝐾𝑖𝑛 + 𝐾𝑠𝑢𝑟𝑓 ) ∙ 𝐻‖ + 𝜆2 ∙ ‖𝐿 ∙ 𝐻‖2 }

104

105

107

𝐹≥0

or,

2

min {‖(𝐺𝑖𝑛 − 𝐾𝑖𝑛 ∙ 𝐻) + (𝐺𝑠𝑢𝑟𝑓 − 𝐾𝑠𝑢𝑟𝑓 ∙ 𝐻)‖ + 𝜆2 ∙ ‖𝐿 ∙ 𝐻‖2 }

𝐹≥0

106

(Eq.S10).

108

Observing the surface term in Eq.S5, notice the maximum value of the surface term is

109

controlled by the position of the actual activity y, but a complement error function

110

dependent solely on the position of the measurement taken (x) controls the final value.

111

Furthermore, for a given G, under the same measurement conditions, Gsurf always has

112

the same set of values. Thus, for a given G, the minimization of the term

113

‖𝐺𝑠𝑢𝑟𝑓 − 𝐾𝑠𝑢𝑟𝑓 ∙ 𝐻‖ will always yield the same solution. As a result, the problem in

114

Eq. S10 can be simplified to:

116

2

min{‖𝐺𝑖𝑛 − 𝐾𝑖𝑛 ∙ 𝐻‖2 + 𝜆2 ∙ ‖𝐿 ∙ 𝐻‖2 }

𝑓≥0

115

(Eq. S11).

6

117

Eq.S11 does not contain the surface term, but the solution of the problem still leads to

118

H, which is the desired original profile. The L-curve method purposed by Hansen &

119

O'Leary (1993) was used to find the best regularization parameter λ.

120

The treatment procedure was coded in MATLAB (version 2013a, MathWorks,

121

Ismaning, Germany), and the inbuilt quadprog was used for solving the minimization

122

problems. L-curve function from the regularization tools (Hansen, 1994) was used to

123

find the λ value. The mean values of triplicates acquired from the microsensor

124

measurement were randomly added or subtracted with a random value in range of the

125

calculated standard deviation (SD) at the same position. These values were used as

126

input for the calculation. The calculation procedure was repeated 3 times, and the

127

mean value of the 3 results was taken as the final result (a SD can also be calculated).

128

Data interpolation, if needed, was done by simply connecting two measured data

129

points with a straight line (linear interpolation, using MATLAB inbuilt function

130

interp1).

7

131

References for supplementary materials:

132

Bergman TL, Lavine AS, Incropera FP, DeWitt DP. 2011. Fundamentals of heat and

133

mass transfer. 7th ed. Hoboken, New Jersey, USA: John Wiley & Sons. 1048 p.

134

Crank J, editor. 1975. Mathematics of diffusion. 2nd ed. Oxford, UK: Oxford

135

University Press. 414 p.

136

Gieseke A, de Beer D. 2004. Use of microelectrodes to measure in situ microbial

137

activities in biofilms, sediments, and microbial mats. In: Kowalchuk GA, de Bruijn

138

FJ, Head IM, Akkermans AD, van Elsas JD, editors. Molecular Microbial Ecology

139

Manual. The Netherlands: Springer. p 3483-3514.

140

Gill PE, Murray W, Wright MH. 1981. Practical optimization. Waltham,

141

Massachusetts, USA: Academic Press. 401 p.

142

Glud RN, Ramsing NB, Revsbech NP. 1992. Photosynthesis and photosynthesis-

143

coupled respiration in natural biofilms quantified with oxygen microsensors. Journal

144

of Phycology 28(1):51-60.

145

Hansen P. 1994. REGULARIZATION TOOLS: A Matlab package for analysis and

146

solution of discrete ill-posed problems. Numerical Algorithms 6(1):1-35.

8

147

Hansen PC, O’Leary DP. 1993. The Use of the L-Curve in the Regularization of

148

Discrete Ill-Posed Problems. SIAM Journal on Scientific Computing 14(6):1487-

149

1503.

150

Hillebrand H, Durselen CD, Kirschtel D, Pollingher U, Zohary T. 1999. Biovolume

151

calculation for pelagic and benthic microalgae. Journal of Phycology 35(2):403-424.

152

Kress R, editor. 2014. Linear integral equations. 3rd ed. New York City, USA:

153

Springer. 412 p.

154

Li T, Podola B, de Beer D, Melkonian M. 2015. A method to determine

155

photosynthetic activity from oxygen microsensor data in biofilms subjected to

156

evaporation. Journal of Microbiological Methods 117:100-107.

157

Polyanin AD. 2002. Handbook of linear partial differential equations for engineers

158

and scientists. Boca Raton, Florida: Chapman&Hall/CRC Press. 800 p.

159

Revsbech NP. 1983. In Situ Measurement of Oxygen Profiles of Sediments by use of

160

Oxygen Microelectrodes. In: Gnaiger E, Forstner H, editors. Polarographic Oxygen

161

Sensors. Berlin/Heidelberg, Germany: Springer. p 265-273.

9

162

Revsbech NP, Jorgensen BB. 1983. Photosynthesis of benthic microflora measured

163

with high spatial-resolution by the oxygen microprofile method - capabilities and

164

limitations of the method. Limnology and Oceanography 28(4):749-756.

165

Tikhonov AN, Goncharsky A, Stepanov VV, Yagola AG. 1995. Numerical methods

166

for the solution of ill-posed problems. Dordrecht, the Netherlands: Springer. 254 p.

Supplementary materials figure captions

167

Figure S1

168

Experimental setup for microsensor studies in non-submerged microalgal biofilms. A:

169

Schematic drawing of the vertical cross section of the measurement in artificial

170

biofilms. Solid arrows in the glass fiber tissue indicate flow direction of the culture

171

medium. B: Schematic drawing of the complete experimental setup, dotted lines with

172

arrow indicate signal flow, whereas solid arrows represent medium and gas flows in

173

the system.

174

Figure S2

175

Schematic drawing of the experimental setup used for biofilm sectioning. The sample

176

holder allows moving the biofilm in vertical direction by means of a micrometer

177

screw (indicated by the thin solid arrows). The biomass above the sectioning plane

10

178

was removed with a solid microtome blade. The cutting direction is indicated by the

179

thick arrow.

11