Biofilms - the Department of Electrical and Systems Engineering

advertisement

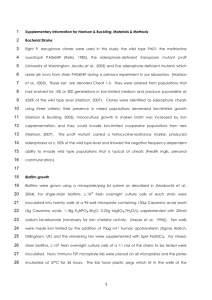

A Multi-disciplinary Senior Design Topic: Biofilms, Electrical Engineering and Sensor Technology: J.N. Zemel, H. Nedwill Ramsey Professor (Emeritus) of Sensor Technologies, zemel@ee.upenn.edu 1. What are Biofilms? Biofilms are ubiquitous and complex biological structures generated by an assemblage of bacterial and/or fungal and/or algae species at a wide variety of interfaces, as illustrated in Figure 1. In some respects, these films resemble a multicellular system. What is intriguing about the biofilm environment is that these different species can promote, protect and propagate the biofilm environment for the benefit of all the different unicellular participants. The substantial variety of single cell species involved in generating complex biofilm structures and the broad conditions under which they prosper are themselves interesting scientifically. Examples are the dental plaque in our mouth and the slime on filter beds in water treatment plants. The latter impacts the power industry since the buildup of biofilms in power plant can seriously impact the efficiency of heat exchangers leading to significant economic costs. However, not all biofilm systems are problematic. One example taken from Figure 1: Illustration of the biofilm community reference 2 is quoted here: “An often cited example of a bacterially produced biopolymer is xanthan gum, produced by Xanthamonas campestris. This biopolymer is produced for use as a thickening agent in a variety of food and consumer products.” 2. Why detecting the earliest stages of biofilm formation is important:? Reference 4 at the end of this document contains the following relevant comment: Sampling strategy The most common way to address biofouling problems is sampling of the water phase. This can usually be performed relatively easily but will provide no information about the location and the extent of deposits on surfaces. It is very important to keep in mind that microbial analysis of the water phase is not suitable to accurately locate or quantify biofilms as the contamination of the water phase occurs not continuously but randomly and does not reflect the site or extent of biofilms in a system. This emphasis on sampling of surfaces may sound trivial, however, in practice, surface sampling is often difficult. “Surface sampling is often difficult.” That statement indicates that a measurement system that can follow the earliest stages of biofilm growth could be a valuable tool for better understanding the attachment, growth and development of the biofilm. What is known is that in the earliest stages of biofilm formation, biopolymers that exist in most conventional water systems deposits on a surface. As this precursor layer forms, planktonic (free floating) cells material that generates the biofilm.. The structure and early characteristics of the biofilms can be studied using a wide variety of microscopic methods involving staining and 1 fluorescence. This works well in the laboratory but a more desirable approach would involve a detection and measurement methodology that can be used on site within systems such as heat exchangers. The aim of this project is to make early surface sampling of biofilm formation simple and routine. 3. What property might be used to detect the early formation of the biofilms? The problem created by the growth and accretion of biofilm is that they impede heat transfer from a surface. The reduction in heat transfer is because their thermal conductivity is significantly lower than that of H2O as evidenced in high temperature heat exchange piping. While this is certainly the end result of biofilm build-up, the reduced thermal conductivity might also be a route for detecting the early stages of biofim accumulation. The major question is whether a sensor method can be devised that is sufficiently sensitive when operated near or at ambient temperatures. 4. A bit of background. Some years ago, there was a graduate program in ESE exploring the use of the pyroelectric effect for monitoring fluid flow (mostly gases), referred to as pyroelectric anemometry or PA (References 4-7). It was shown that: (a) the physical process involved was convective heat flow from the solid to the gas; (b) the thermal conductivity of the gas was the major variable controlling the signal level; (c) the sensitivity of the measurement was exquisite and covered almost 5 orders of magnitude in flow; the measurements were extraordinarily reproducible from device to device. Measurements of liquid flow have not been carried out so that would be the first order of business. That is, to build a system/device to measure the operational characteristics of a water-based PA. The fundamental properties of the PA won’t change in going from a gas like argon to liquid water since the operation of the PA depends on convective heat transfer at the surface. It should be kept in mind that heat transfer is the central issue in this proposed project. If the surface is gunked up with a biofilm, the heat transfer will be seriously impacted. Because biofilms on solid surfaces impede thermal transport from the solid, this property provides a possible means for detecting their early growth, provided the sensors employed have adequate thermal sensitivity. As can be seen in references 1-3, the heat transfer from a sold surface to water drops when the biofilm forms and not infrequently the drop is profound. To measure the changes in the PA signal generated as a biofim grows, sensitive analog and digital electronics are needed. The design and construction of a suitable flow system is likely to include microfabricated microfluidic structures (see reference 7) into which currently available PA chips would be incorporated. In summary, what is proposed here is an extension of a known measurement technology based on well-established scientific and engineering principles to address a known problem created by biological life forms. It’s an interdisciplinary effort that offers insight into how engineering and biology can cooperate to address a real industrial issue. 5. A brief aside on EE education. While computers, communication and control are core aspects of any EE education, there is growing awareness that the rapid growth and expansion of pure and applied biology is having a profound impact in engineering. The tools and methods of the physical sciences 2 (chemistry, physics and engineering) play central roles in contemporary biological areas of industry and academia. The proposed project presented below illustrates how the application of material physics, thermal engineering, electronics and microfluidics/microfabrication technology could lead to a device that provides useful information on the early growth and development of this extraordinary life form, the biofilm. Some Reference Material (I found that Firefox is best for viewing the first 3 documents): 1. If you are interested in this project, I urge you to scan through the material presented in http://www.biofilm.montana.edu/. A variety of overviews of both the behavior and industrial significance of biofilms is available on Google’s “Biofilm Thermal Conductivity” search site. I haven’t found too much on the Penn Library website 2. A good overview can also be found at http://www.wet-usa.com/data/bullets/46.pdf . Note that most of the discussion related to significant deposits of biofilm material rather than early stage detection, what I hope will be possible with PA based system. 3. Another interesting document from a European consortium is found at: http://www.efcweb.org/efcweb_media/Downloads/EFC+WP10/BR99_02b.pdf Methods for Investigation of Biofilms, 1999 Steps in biofilm sampling and characterization in biofouling cases Gabriela Schaule1, Thomas Griebe2 and Hans-Curt Flemming2 1 IWW Center for Water Research, Moritzstr. 26, D- 45476 Mülheim 2 University of Duisburg, Dep. Aquatic Microbiology, Geibelstr. 41, D-47057 4. H. Y. Hsieh, J. N. Zemel and Haim H. Bau "Pyroelectric Anemometry: Theory of Operation",Sensors and Actuators, A49, 125-132, (1995). 6. H. Y. Hsieh, and J. N. Zemel, "Pyroelectric Anemometry: Frequency, Geometry And Gas Dependence",Sensors and Actuators, A49, 133-140, (1995) 7. H. Y. Hsieh, A. Spetz and J. N. Zemel, "Pyroelectric Anemometry: Vector and Swirl Measurements", Sensors and Actuators, A49, 141-147, (1995) 8. Yu Dun, H. Y. Hsieh, and J N. Zemel, "Microchannel Pyroelectric Anemometers for Gas Flow Measurements", 39, 29-35, 1993 3