Yes - Process Control Education

advertisement

McMaster University

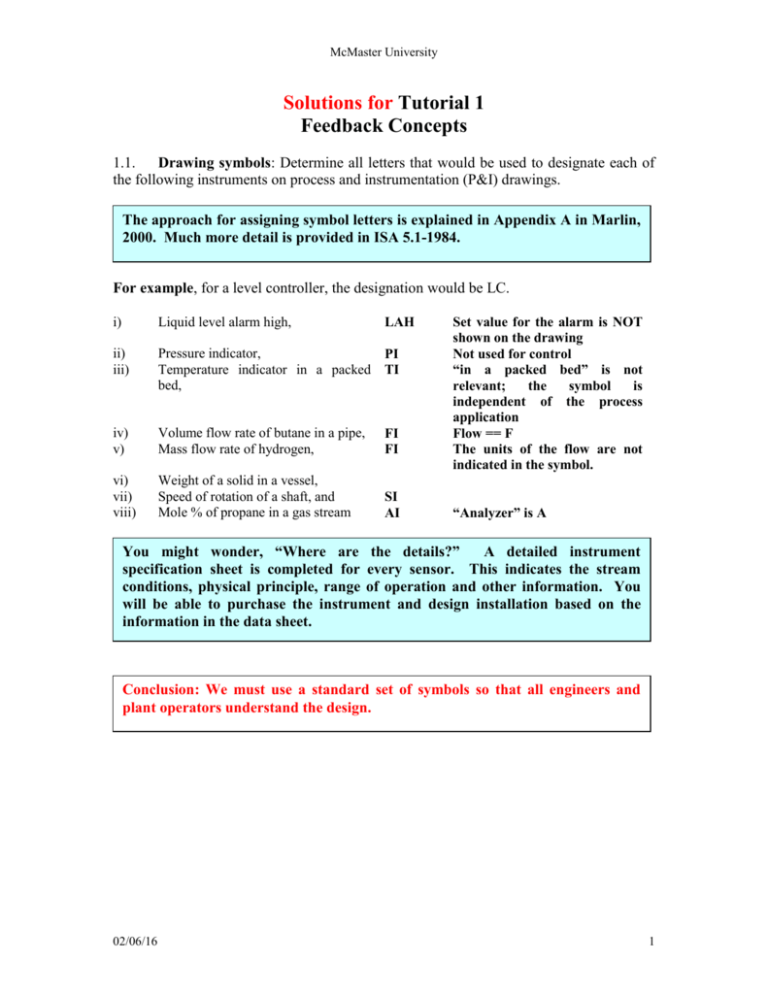

Solutions for Tutorial 1

Feedback Concepts

1.1. Drawing symbols: Determine all letters that would be used to designate each of

the following instruments on process and instrumentation (P&I) drawings.

The approach for assigning symbol letters is explained in Appendix A in Marlin,

2000. Much more detail is provided in ISA 5.1-1984.

For example, for a level controller, the designation would be LC.

i)

Liquid level alarm high,

ii)

iii)

Pressure indicator,

PI

Temperature indicator in a packed TI

bed,

iv)

v)

Volume flow rate of butane in a pipe,

Mass flow rate of hydrogen,

FI

FI

vi)

vii)

viii)

Weight of a solid in a vessel,

Speed of rotation of a shaft, and

Mole % of propane in a gas stream

SI

AI

LAH

Set value for the alarm is NOT

shown on the drawing

Not used for control

“in a packed bed” is not

relevant;

the

symbol

is

independent of the process

application

Flow == F

The units of the flow are not

indicated in the symbol.

“Analyzer” is A

You might wonder, “Where are the details?”

A detailed instrument

specification sheet is completed for every sensor. This indicates the stream

conditions, physical principle, range of operation and other information. You

will be able to purchase the instrument and design installation based on the

information in the data sheet.

Conclusion: We must use a standard set of symbols so that all engineers and

plant operators understand the design.

02/06/16

1

McMaster University

1.2. Common examples of automation: Discuss whether each of the common

systems below uses automatic feedback to achieve its desired performance.

Note: The question asks if automatic feedback is applied. “Automatic” implies

the use of a computing device, such as a digital computer. Feedback could be

applied by a person, which is generally not as reliable. We’re smart but we get

tired.

a.

Boiling water on a burner in a home stove.

The burner is set to a constant gas flow or electrical power, and no automatic

adjustment is applied to achieve a desired rate of boiling.

Note that the temperature is constant when the water is boiling, regardless of the

heating applied. This is NOT due to control, but is a result of the process

principles.

b.

Maintaining a temperature in an oven in a home stove.

The typical home oven has a temperature controller. The automatic approach is

not complex; it applies and on/off feedback algorithm. If the temperature is

below a set point, the furnace is turned on; if the temperature is above a set point,

the furnace is turned off. Usually, a “dead band” is applied to prevent the heater

from switching on and off too frequently.

c.

An alarm clock used to wake you for class.

No automatic mechanism is applied to the alarm clock. If the power fails, the

clock cannot recognize this and correct. Also, if you do not awake, the clock stops

sounding the alarm after a specified time.

So, the success of the alarm depends on our participation, which we regret every

morning.

Conclusion: We apply automatic feedback control when we desire reliable

application of a consistent policy.

02/06/16

2

McMaster University

1.3.

A Chemical Engineering Example: A chemical reactor with recycle is depicted in

textbook Figure 1.8 and repeated below.

a.

Can the following variable be controlled by feedback? Hint: determine which valves have a

causal effect on each sensor.

b.

Select the best valve to control each, if more than one valve can effect the sensor.

c.

Select a sensor principle for each of the sensors. (Hint: Check the WEB site!)

i.

ii.

T4, reactor feed temperature

T1, feed temperature

iii.

iv.

F3, reactor effluent flow

L1, reactor liquid level

v8

F2

F1

T1

T3

v3

F5

T5

P1

T4

F3

T6

F4

L1

v1

v5

v2

v6

v7

T2

Hot Oil

L1

T7

T8

T9

Hot Oil

F6

Figure 1.1

v1 Yes,

strong

v2 Yes,

strong

v3 Yes,

weak

v4 Yes,

temporary

v5 no

v6 no

v7 Yes,

weak

v8 Yes,

weak

T4, reactor temperature

This will influence the flow rate through the feed exchanger and

the ratio of fresh to recycle, which can be at different

temperatures.

This will affect the flow of heating oil to the feed heat exchanger.

This will affect the flow rate of both fresh and recycle feeds,

without changing the ratio.

This will change the recycle flow temporarily. Note that the

supply of recycle material is limited that the average over time can

be no more (or less) than what remains liquid in the flash drum.

This affects the flow out of the reactor.

See v5 above

This will affect the heat to the reactor effluent, which influences

the flow rate and temperature of the recycle.

This will affect the pressure in the flash drum and thus, the

fraction of reactor effluent that is vapor. The liquid recycles to

the reactor.

The best choice should provide a fast and strong effect on T4 and leave valves for

other important controllers. Let’s select v2.

Because this is a reactor, we could select an RTD sensor for good accuracy, but we

need more information.

02/06/16

3

McMaster University

1.4 When we consider history, we encounter a puzzle. Automatic control has been

applied for a long time. Certainly, scientists and engineers needed automatic

control since the time of the steam engine to prevent explosions and maintain the

driver speed at a desired valve. (Actually, before then, but let’s use the revolution of

the steam engine as our marker in history.) However, digital computers were not

available for these purposes until after World War II. In fact, digital control did

not begin until the 1960’s.

So, how was automatic control implemented physically before digital computation?

As usual, we have been preceded by many clever people who were able to

overcome limitations to achieve their goals. Before digital computers, we

employed a concept of “analog computation”. In analog computation, we build a

physical device that behaves in the same way as the calculation we intend to

implement. To be feasible, we typically limit ourselves to relatively simple

calculations. Even so, considerable ingenuity is required.

Let’s look an example of a simple process

control application. We have a tank containing

liquid that supplies a downstream process. The

flow rate to the downstream process depends

on the production rate, which changes in an

unpredictable manner.

It is our task to

maintain the liquid level in the tank at a desired

value (let’s say at 50% of the tank height) by

manipulating the flow into the tank. Why? If

the level were not controlled,

Flow into

tank

Flow out to

downstream

process

It could overflow and cause loss of valuable material, or perhaps, a hazard

It could decrease to zero. Then, not liquid would be available to the process and

we would have to stop production.

First, we decide to use the feedback principle. This requires a measurement of the

level and adjustment of a causal variable. We will select a very simple automatic

control strategy, but one that is very widely used, as we will see later. We chose

to manipulate the flow in proportion to the amount that the level deviates from its

desired value. The feedback approach is given in the following equation.

Fin F0 K c ( L Ldesired )

with

F0

Ldesired

L

Kc

02/06/16

= the base case flow

= the desired level

= the measured (actual) level

= an adjustable constant, which we will later call the controller gain

4

McMaster University

We want this implemented without human interference, i.e., we seek automatic

control. This calculation would be easy via digital computation. How would you

have achieved this in 1895?

Let’s look at one way. We implement the calculation using a mechanical analog

computation. The mechanism is shown in the sketch below.

Lets look at each element of the automatic control device.

Sensor: The level is measured by a float, whose position indicates the

level.

Final Element: The flow in is influenced by a “gate”, whose position

determines the flow rate. As the gate position is elevated, the opening for

flow increases, as does the flow.

Controller: The controller is a lever that can rotate about a fulcrum. As

the float increases (decreases), the connecting rod forces the level to

decrease (increase) the gates’ position.

This device exactly implements our strategy and the control equation! It is

simple, inexpensive, and reliable (does not require electricity). However, it is not

very flexible. If we want to change the proportionality constant (Kc), we have to

change the location of the fulcrum.

Current process control technology takes advantage of digital computation to

achieve tremendous increases in process safety, product quality and profitability.

However, let’s not forget the ingenious pioneers who established automatic

control by solving practical problems with the tools and technology available at

the time!

02/06/16

5

McMaster University

Solutions for Tutorial 2

Control Objectives & Benefits

2.1 We will invest lots of effort understanding process dynamics between “inputs” and

“outputs”. The outputs are key variables that we want to maintain at or near specified

desired values. The inputs belong to two distinct categories.

1.

2.

Manipulated variables that we adjust to achieve desired process behavior

Disturbance variables whose values vary due to changes in other processes and

the surrounding environment.

If no disturbances occurred, there would be little need for process control; however,

disturbances occur to essentially every process.

Let’s look at an example process and find some examples of variables in each of the two

categories. The process in Figure 2.1 vaporizes liquid butane and mixes the vapor with

compressed air. The mixture flows to a packed bed reactor.

Figure 2.1

02/06/16

6

McMaster University

a.

b.

c.

Identify at least three controlled variables, which must be measured.

Identify at least one manipulated variable for each of the controlled variables.

Hint: these must be valves.

Identify at least three disturbance variables. (These do not have to be measured.)

For each, determine which controlled variable(s) are influenced, i.e., disturbed.

a.

Controlled variables

1. Pressure of the vaporizer (P1), which is important for safety.

2. Liquid level in the vaporizer (L1), which influences the amount vaporized. It

should not overflow the vessel or drain empty.

3. The percentage of butane in the mixed stream (A1), which is important if we

are to avoid an explosive concentration!

b.

Manipulated variables

1. The vapor lease from the vaporizer (v3). This has a causal relationship with the

pressure and can be adjusted to control P1.

2. The flow of liquid butane from storage to the vaporizer (v1). This has a causal

relationship with the liquid level and can be adjusted to control L1.

3. The flow of air is affected by the valve in the compressor suction, v4. This has

a causal relationship with the flow of air and the mixture composition and can be

adjusted to control A1.

c.

Disturbances

1. Steam pressure that influences the heat transfer in the vaporizer and affects P1

and L1.

2. Air temperature that influences the compressor performance and affects the

mixture composition.

3. Pressure downstream from the reactor that influences the flows of butane and

air.

02/06/16

7

McMaster University

2.2

Economic benefits: Discuss the economic benefits achieved by reducing the

variability (and, in some cases changing the average value) of the key controlled variable

for the situations in the following.

a.

Crude oil is distilled, and one segment of the oil is converted in a chemical reactor

to make gasoline. The reactor can be operated over a range of temperatures; as

the temperature is increased, the octane of the gasoline increases, but the yield of

gasoline decreases because of increased by-products of lower value. (It’s not

really this simple, but the description captures the essence of the challenge.) The

customer cannot determine small changes in octane. You are responsible for the

reactor operation. Is there a benefit for tight temperature control of the packed

bed reactor? How would you determine the correct temperature value?

Octane

Time

Gasoline yield, %

Maximum possible yield

Average yield achieved

because of “backoff”

from limit

Minimum

Octane

In this situation, the customer cannot distinguish small changes from the

minimum octane when driving their automobiles. Therefore, this small deviation

in product quality is acceptable. However, the variability in the octane results in

a lower average yield of gasoline and a higher yield of lower valued byproducts.

Tight control of reactor temperature will reduce the variability in octane and

allow a higher average yield of valuable gasoline. The average temperature can

be selected to achieve acceptable octane for all production within the variation.

Note that the goal here is to reduce variability and adjust the average value to

increase profit.

02/06/16

8

McMaster University

b.

You are working at a company that produces large roles of paper sold to

newspaper printers. Your client has many potential suppliers for this paper. Your

customer can calibrate the printing machines, but after they have been calibrated,

changes to paper thickness can cause costly paper breaks in the printing machines.

Discuss the importance of variance to your customer, what your product quality

goal would be. Is this concept different from the situation in part (a) of this

question?

Desired thickness

Average

number

of breaks

Paper thickness

In this situation, the average paper thickness is not extremely important, so long

as the customers can calibrate their machinery. However, after you and the

customers have agreed on a thickness, essentially any variation is harmful,

because it increases the likelihood of paper breaks. The customers lose

production time, paper, and perhaps, the workers are subject to hazardous

conditions. If you do not supply consistent thickness, the customer will find

another supplier.

Therefore, the goal here is to retain the agreed average and reduce the

variability to the minimum achievable.

02/06/16

9

McMaster University

2.3 The data in Figure 2.3 reports experience in a blending of Residuum and more

expensive Gas Oil to produce a product with upper and lower viscosity specifications.

The “before” data represents manual operation by plant personnel. The “after” data

represents feedback control using a computer and a on-stream viscosity analyzer.

Discuss the performance and the source of benefits.

Figure 2.3

The “before data is typical of poor control for a variable with upper and lower

bounds. The nature tendency is to maintain the variable close to the “middle” of

the range. This approach allows for the greatest variability without exceeding

either bound. However, the average viscosity is low, which indicates that

excessive expensive Gas Oil has been consumed and cannot be sold at a higher

price.

After analyzer feedback has been implemented, the variability has been reduced,

which allows the average value of the viscosity to be increased without exceeding

the bounds. Increased profit results from less use of Gas Oil in this lower value

product, which can be sold at a higher value.

02/06/16

10

McMaster University

Solutions for Tutorial 3

Modelling of Dynamic Systems

3.1

Mixer: Dynamic model of a CSTR is derived in textbook Example 3.1. From the

model, we know that the outlet concentration of A, CA, can be affected by manipulating

the feed concentration, CA0, because there is a causal relationship between these

variables.

a.

b.

c.

The feed concentration, CA0, results from mixing a stream of pure A with solvent,

as shown in the diagram. The desired value of CA0 can be achieved by adding a

right amount of A in the solvent stream. Determine the model that relates the

flow rate of reactant A, FA, and the feed concentration, CA0, at constant solvent

flow rate.

Relate the gain and time constant(s) to parameters in the process.

Describe a control valve that could be used to affect the flow of component A.

Describe the a) valve body and b) method for changing its percent opening

(actuator).

Fs

Solvent

CA,solvent

Fo

CAO

F1

CA

Reactant

FA

CA,reactant

Figure 3.1

a.

In this question, we are interested in the behavior at the mixing point, which is

identified by the red circle in the figure above. We will apply the standard modelling

approach to this question.

Goal: Determine the behavior of CA0(t)

System: The liquid in the mixing point. (We assume that the mixing occurs essentially

immediately at the point.)

02/06/16

11

McMaster University

Balance: Since we seek the behavior of a composition, we begin with a component

balance.

Accumulation

(1)

=

in

-

out

+ generation

MWA Vm C A0 | t t Vm C A0 | t MX A t FS C AS FA C AA (FS FA C A0 ) 0

Note that no reaction occurs at the mixing point. We cancel the molecular weight, divide

by the delta time, and take the limit to yield

(2)

FS

Vm

dC A

FA

C AS

C AA C A 0

(FS FA ) dt

FS FA

FS FA

No reactant (A) appears in the solvent, and the volume of the mixing point is very small.

Therefore, the model simplifies to the following algebraic form.

(3)

FA

C AA C A 0

FS FA

Are we done? We can check degrees of freedom.

DOF = 1 – 1 = 0

CA0

Therefore, the model is complete.

(FS, FA, and CAA are known)

You developed models similar to equation (3) in your first course in Chemical

Engineering, Material and Energy balances. (See Felder and Rousseau for a refresher.)

We see that the dynamic modelling method yields a steady-state model when the time

derivative is zero.

Note that if the flow of solvent is much larger than the flow of reactant, FS >> FA, then,

(4)

C

C A 0 AA FA

FS

If FS and CAA (concentration of pure reactant) are constant, the concentration of the

mixed stream is linearly dependent on the flow of reactant.

b. For the result in equation (4),

Time constant = 0

(This is a steady-state process.)

Gain = CAA/FS

(The value will change as FS is changed.)

02/06/16

12

McMaster University

c. The control valve should have the following capabilities.

1.

2.

3.

Introduce a restriction to flow.

Allow the restriction to be changed.

Have a method for automatic adjustment of the restriction, not requiring

intervention by a human.

1&2

These are typically achieved by placing an adjustable element near a restriction

through which the fluid must flow. As the element’s position in changed, the area

through which the fluid flows can be increased or decreased.

3

This requirement is typically achieved by connecting the adjustable element to a

metal rod (stem). The position of the rod can be changed to achieve the required

restriction. The power source for moving the rod is usually air pressure, because

it is safe (no sparks) and reliable. A rough schematic of an automatic control

valve is given in the following figure.

air pressure

diaphram

spring

valve stem position

valve plug and seat

See a Valve

You can see a picture of a typical control valve by clicking here.

Many other valves are used, but this picture shows you the key

features of a real, industrial control valve.

Hint: To return to this current page after seeing the valve, click

on the “previous view” arrow on the Adobe toolbar.

You can read more about valves at the McMaster WEB site.

02/06/16

13

McMaster University

3.2

a.

b.

c.

d.

Stirred tank mixer

Determine the dynamic response of the tank temperature, T, to a step change in

the inlet temperature, T0, for the continuous stirred tank shown in the Figure 3.2

below.

Sketch the dynamic behavior of T(t).

Relate the gain and time constants to the process parameters.

Select a temperature sensor that gives accuracy better than 1 K at a temperature

of 200 K.

F

T0

F

T

V

Figure 3.2

We note that this question is a simpler version of the stirred tank heat exchanger in

textbook Example 3.7. Perhaps, this simple example will help us in understanding the

heat exchanger example, which has no new principles, but more complex algebraic

manipulations. Remember, we use heat exchangers often, so we need to understand their

dynamic behavior.

a/c. The dynamic model is derived using the standard modelling steps.

Goal: The temperature in the stirred tank.

System: The liquid in the tank. See the figure above.

Balance: Since we seek the temperature, we begin with an energy balance.

02/06/16

14

McMaster University

Before writing the balance, we note that the kinetic and potential energies of the

accumulation, in flow and out flow do not change. Also, the volume in the tank is

essentially constant, because of the overflow design of the tank.

accumulation

(1)

U | t t

=

in

-

out

(no accumulation!)

U | t t (H in H out )

We divide by delta time and take the limit.

(2)

dU

(H in H out )

dt

The following thermodynamic relationships are used to relate the system energy to the

temperature.

dU/dt = VCv dT/dt

H = FCp (T-Tref)

For this liquid system, Cv Cp

Substituting gives the following.

(3)

V

dT

F(T0 T)

dt

Are we done? Let’s check the degrees of freedom.

DOF = 1 –1 = 0

T

(V, and T0 known)

This equation can be rearranged and subtracted from its initial steady state to give

(4)

dT'

T' KT ' 0

dt

with = V/F

K=1

Note that the time constant is V/F and the gain is 1.0. These are not always true!

We must derive the models to determine the relationship between the process and

the dynamics. See Example 3.7 for different results for the stirred tank heat

exchanger.

02/06/16

15

McMaster University

The dynamic response for the first order equation

differential equation to a step in inlet temperature

can be derived in the same manner as in

Examples 3.1, 3.2, etc. The result is the

following expression.

(5)

T' KT0 (1 e t / )

and

T Tinitial KT0 (1 e t / )

T

Time

T0

d. We base the temperature sensor selection on

Time

the information on advantages and disadvantages

of sensors. A table is available on the McMaster WEB site, and links are provided to

more extensive sensor information. A version of such a table is given below.

Since a high accuracy is required for a temperature around 200 K, an RTD (a sensor

based on the temperature sensitivity of electrical resistance) is recommended. Even this

choice might not achieve the 1 K accuracy requirement.

limits of

application

(C)

accuracy (1,2)

thermocouple

type E

(chromel-constantan)

-100 to 1000

1.5 or 0.5%

(0 to 900 C)

type J

(iron-constantan)

0 to 750

2.2 or 0.75%

type K

(chromel-nickel)

0 to 1250

2.2 or 0.75%

type T

(copper-constantan)

-160 to 400

RTD

-200 to 650

1.0 or 1.5%

(-160 to 0 C)

(0.15 +.02 T) C

Thermister

-40 to 150

0.10C

sensor type

advantages

disadvantages

(3)

1. good reproducibility

2. wide range

1. minimum span, 40 C

2. temperature vs emf

not exactly linear

3. drift over time

4. low emf corrupted by

noise

(3)

1. good accuracy

2. small span possible

3. linearity

(3)

1. good accuracy

2. little drift

1. self heating

2. less physically

rugged

3. self-heating error

1. highly nonlinear

2. only small span

3. less physically

rugged

4. drift

1. local display

2%

Bimetallic

Filled system

dynamics,

time

constant (s)

-200 to 800

1%

1-10

1.

2.

1.

2.

low cost

physically rugged

simple and low cost

no hazards

1. not high temperatures

2. sensitive to external

pressure

1. C or % of span, whichever is larger

2. for RTDs, inaccuracy increases approximately linearly with temperature deviation from 0 C

3. dynamics depend strongly on the sheath or thermowell (material, diameter and wall thickness), location of element in the sheath (e.g.,

bonded or air space), fluid type, and fluid velocity. Typical values are 2-5 seconds for high fluid velocities.

02/06/16

16

McMaster University

3.3

Isothermal CSTR: The model used to predict the concentration of the product,

CB, in an isothermal CSTR will be formulated in this exercise. The reaction occurring in

the reactor is

AB

rA = -kCA

Concentration of component A in the feed is C A0, and there is no component B in the

feed. The assumptions for this problem are

F0

1.

2.

3.

4.

5.

6.

7.

the tank is well mixed,

negligible heat transfer,

constant flow rate,

constant physical properties,

constant volume,

no heat of reaction, and

the system is initially at steady state.

CA0

F1

V

CA

Figure 3.3

a.

b.

b.

c.

d.

Develop the differential equations that can be used to determine the dynamic

response of the concentration of component B in the reactor, CB(t), for a given

CA0(t).

Relate the gain(s) and time constant(s) to the process parameters.

After covering Chapter 4, solve for CB(t) in response to a step change in CA0(t),

CA0.

Sketch the shape of the dynamic behavior of CB(t).

Could this system behave in an underdamped manner for different (physically

possible) values for the parameters and assumptions?

In this question, we investigate the dynamic behavior of the product concentration for a

single CSTR with a single reaction. We learned in textbook Example 3.2 that the

concentration of the reactant behaves as a first-order system. Is this true for the product

concentration?

a. We begin by performing the standard modelling steps.

Goal: Dynamic behavior of B in the reactor.

System: Liquid in the reactor.

Balance: Because we seek the composition, we begin with a component material

balance.

Accumulation =

02/06/16

in

-

out

+

generation

17

McMaster University

(1)

MWB (VC B | t t VC B | t ) MWB t (FC B0 FC B VkC A )

We can cancel the molecular weight, divide by delta time, and take the limit to obtain the

following.

(2)

V

dC B

FC B0 FC B VkC A

dt

0

We can subtract the initial steady state and rearrange to obtain

(3)

B

dC' B

C' B K B C' A

dt

A

V

F

KB

Vk

F

Are we done? Let’s check the degrees of freedom.

DOF = 2 – 1 = 1 0

No!

CB and CA

The first equation was a balance on B; we find that the variable C A remains. We first see

if we can evaluate this using a fundamental balance.

Goal: Concentration of A in the reactor.

System: Liquid in the reactor.

Balance: Component A

(4)

MWA (VC A | t t VC A | t ) MWA t (FC A0 FC A VkC A )

Following the same procedures, we obtain the following.

(5)

A

dC' A

C' A K B C' A 0

dt

A

V

F Vk

KA

F

F Vk

Are we done? Let’s check the degrees of freedom for equations (3) and (5).

DOF = 2 – 2 = 0

Yes!

CB and CA

The model determining the effect of CA0 on CB is given in equations (3) and (5).

02/06/16

18

McMaster University

b. The relationship between the gains and time constants and the process are given in

equations (3) and (5).

c. We shall solve the equations for a step in feed concentration using Laplace transforms.

First we take the Laplace transform of both equations; then we combine the resulting

algebraic equations to eliminate the variable CA.

(6)

B sC' B (s) C' B (t ) | t 0 C' B (s) K B C' A (s)

(7)

A sC' A (s) C' A (t ) | t 0 C' A (s) K A C' A0 (s)

(8)

C' B (s)

KAKB

C' A0 (s)

( A s 1)( B s 1)

We substitute the input forcing function, C’A0(s) = CA0/s, and invert using entry 10 of

Table 4.1 (with a=0) in the textbook.

(9)

(10)

C' B (s)

C' A 0

KAKB

( A s 1)( B s 1) s

A

B

C' B ( t ) K A K B C A 0 1

e t / A

e t / B

B A

B A

c. The shape of the response of CB using the numerical values from textbook Example 3.2

is given in the following figure. Note the overdamped, “S-shaped” curve.

This is much different from the response

of CA.

solid = CB

1

0.8

Compare the responses and explain the

differences.

0.6

0.4

d. Because the roots of the denominator

in the Laplace transform are real, this

process can never behave as an

underdamped system.

0

20

40

60

time

80

100

120

0

20

40

60

time

80

100

120

2

1.5

1

0.5

02/06/16

19

McMaster University

3.4

Inventory Level: Process plants have many tanks that store material. Generally,

the goal is to smooth differences in flows among units, and no reaction occurs in these

tanks. We will model a typical tank shown in Figure 2.4.

a.

Liquid to a tank is being determined by another part of the plant; therefore, we have

no influence over the flow rate. The flow from the tank is pumped using a

centrifugal pump. The outlet flow rate depends upon the pump outlet pressure and

the resistance to flow; it does not depend on the liquid level. We will use the valve

to change the resistance to flow and achieve the desired flow rate. The tank is

cylindrical, so that the liquid volume is the product of the level times the cross

sectional area, which is constant.

Assume that the flows into and out of the

tank are initially equal. Then, we

decrease the flow out in a step by

adjusting the valve.

Fin

L

i.

Determine the behavior of the

level as a function of time.

Fout

V=AL

Figure 2.4

We need to formulate a model of the process to understand its dynamic behavior. Let’s use

our standard modelling procedure.

Goal: Determine the level as a function of time.

Variable: L(t)

System: Liquid in the tank.

Balance: We recognize that the level depends on the total amount of liquid in the tank.

Therefore, we select a total material balance. Note that no generation term appears in the

total material balance.

(accumulation) = in - out

( AL) t t ( AL) t Fin t Fout t

We cancel the density, divide by the delta time, and take the limit to yield

A

02/06/16

dL

Fin Fout

dt

20

McMaster University

The flow in and the flow are independent to the value of the level. In this problem, the

flow in is constant and a step decrease is introduced into the flow out. As a result,

A

dL

Fin Fout constant 0

dt

We know that if the derivative is constant, i.e., independent of time, the level will increase

linearly with time. While the mathematician might say the level increases to infinity, we

know that it will increase until it overflows. Thus, we have the following plot of the

behavior.

To infinity

Overflow!

L

Fin

Fout

time

Note that the level never reaches a steady-state value (between overflow and

completely dry). This is very different behavior from the tank concentration that we

have seen. Clearly, we must closely observe the levels and adjust a flow to maintain

the levels in a desirable range. If you are in charge of the level – and you do not have

feedback control – you better not take a coffee break!

The level is often referred to as an integrating process – Why? The level can be determined

by solving the model by separation and integration, as shown in the following.

A dL ( Fin Fout )dt

L A ( Fin Fout )dt

Thus, the level integrates the difference between inlet and outlet flows.

02/06/16

21

McMaster University

ii.

Compare this result to the textbook Example 3.6, the draining tank.

Fin

Fin

L

Fout

L

Fout

V=AL

Key Issue

Level model

Flow out

Level behavior

Level stability

iii.

Example 3.6

Draining tank

This question

Tank with outlet pump

By overall material balance

Depends on the level

By overall material balance

Independent of the level

(or very nearly so)

First order exponential for a step Linear, unbounded response

change

to a step change

stable

unstable

Describe a sensor that could be used to measure the level in this vessel.

Naturally, we could tell you the answer to this question. But, you will benefit more from

finding the answer. Click to access the instrumentation resources and review Section 2.4

and links to more detailed resources. CLICK HERE

02/06/16

22

McMaster University

3.5

Designing tank volume: In this question you will determine the size of a storage

vessel. Feed liquid is delivered to the plant site periodically, and the plant equipment is

operated continuously. A tank is provided to store the feed liquid. The situation is

sketched in Figure 3.5. Assume that the storage tank is initially empty and the feed

delivery is given in Figure 2.5. Determine the minimum height of the tank that will prevent

overflow between the times 0 to 100 hours.

Fin

Fout = 12.0 m3/h

L=?

A = 50 m2

30.0

Fin

(m3/h)

End of problem at 100 h

0

0

20

40 50

70 80

Time (h)

Figure 3.5 Tank between the feed delivery and the processing units.

This problem shows how the dynamic behavior of a process unit can be important in

the design of the process equipment.

Our approach to solving the problem involves determining the liquid volume over the

complete time period from 0 to 100 hours. The maximum volume during the period can be

used to evaluate the size of the tank; any tank smaller would experience an overflow.

The dynamic model for the tank was formulated in the previous solution, which we will

apply in this solution. The behavior of the system is summarized in the following table and

sketched in the figure.

Time (h)

Fin

Fout (m3/h)

dV/dt = Fin -Fout

(m3/h)

0 - 20

20-40

40-50

50-70

70-80

80-100

30

0

30

0

30

30

12

12

12

12

12

12

18

-12

18

-12

18

-12

02/06/16

V beginning

of period

(m3)

0

360

120

300

60

240

V end of

period

(m3)

360

120

300

60

240

0

23

McMaster University

Volume (m3)

400

300

200

100

0

0

20

40

50

70

80

100

time (h)

We see in the table and figure that the maximum volume is 360 m3. Since the cross

sectional area is 50 m2, the minimum height (or level) for the tank is calculated to be 7.2 m.

L = 360 m3 / 50 m2 = 7.2 m

We should note that this calculation results in the tank being completely full at t = 20

hours; there is no margin for error. We should look into the likely variability of the feed

deliveries and the production rates before making a final decision on the correct volume.

3.6

Modelling procedure: Sketch a flowchart of the modelling method that we are

using to formulate dynamic models.

We should develop this type of sketch so that we can visualize the procedure and clarify

the sequence of steps. A flowchart is given on the following page. Did yours look

similar?

02/06/16

24

McMaster University

Flowchart of Modeling Method

(We have not yet done the parts in the yellow boxes)

Goal:

Assumptions:

Data:

Variable(s): related to goals

System: volume within which variables are independent of position

Fundamental Balance: e.g. material, energy

DOF = 0

Check DOF 0 Another balance:

-Fundamental balance

D.O.F.

-Constitutive equations

[e.g.: Q =hA(Th-Tc)]

Is model linear?

Yes

No

Expand in Taylor Series

Express in deviation variables

Group parameters to evaluate [gains (K), time-constants (), dead-times()]

Take Laplace transform

Substitute specific input, e.g.,

step, and solve for output

Analytical solution

(step)

Numerical solution

Analyze the model for:

- causality

- order

- stability

- damping

Combine several models into

integrated system

02/06/16

25

McMaster University

Solutions for Tutorial 4

Modelling of Non-Linear Systems

4.1

Isothermal CSTR: The chemical reactor shown in textbook Figure 3.1 and

repeated in the following is considered in this question. The reaction occurring in the

reactor is

AB

rA = -kCA0.5

The following assumptions are appropriate for the system.

(i) the reactor is well mixed,

(ii) the reactor is isothermal,

(iii) density of the liquid in the reactor is constant,

(iv) flow rates are constant, and

(v) reactor volume is constant.

a.

b.

c.

d.

e.

Formulate the model for the dynamic response of the concentration of A in the

reactor, CA(t).

Linearize the equation(s) in (a).

Solve the linearized equation analytically for a step change in the inlet

concentration of A, CA0.

Sketch the dynamic behavior of CA(t).

Discuss how you would evaluate the accuracy of the linearized model.

Goal

Variable

System

Balance

(or constitutive equation)

DOF

Linear?

Again, we apply the standard modelling approach, with a check for linearity.

a. Goal: Determine composition of A as a function of time.

Variable: CA in the reactor

System: The liquid in the reactor.

Balance: Component balance on A.

Accumulation

(1)

02/06/16

=

in

-

out

MWA VC A | t t VC A | t MWA t FCA0 FCA VkC 0A.5

+

generation

26

McMaster University

Divide by delta time and take the limit to obtain

(2)

V

dC A

F(C A 0 FC A ) VkC 0A.5

dt

Are we done? Let’s check the degrees of freedom.

DOF = 1 - 1 = 0

Yes!

b. Is the model linear? If we decide to solve the model numerically, we do not have to

linearize; in fact, the non-linear model would be more accurate. However, in this

problem we seek the insight obtained from the approximate, linear model.

All terms involve a constant times a variable (linear) except for the following term, which

is linearized using the Taylor series..

(3)

C 0A.5 C 0A.5

s

0.5 C A0.5

C

s

A

C As higher order terms

This approximation can be substituted into equation 2, and the initial steady-state model

subtracted to obtain the following, with C’A = CA - CAS.

(4)

V

dC' A

F(C' A 0 FC' A ) Vk (0.5C As0.5 )C' A

dt

This linear, first order ordinary differential equation model can be arranged into the

standard form, given in the following.

(5)

dC' A

C' A KC ' A 0

dt

with

V

F 0.5VkC

0.5

As

K

F

F 0.5VkC As0.5

c. Let’s solve this equation using the Laplace transform method. We can take the

Laplace transform of equation (5) to obtain

(6)

sC' A (s) C' A (t ) | t 0 C' A (s) KC' A0 (s)

Note that equation (6) is general for any function CA0(t). We can rearrange this equation

and substitute the Laplace transform of the step change in feed composition

(C’A0(s)=CA0/s to give.

(7)

02/06/16

C' A (s)

K C A 0

s 1 s

27

McMaster University

We can take the inverse Laplace transform using entry 5 in textbook Table 4.1 to give

(8)

C' A (t ) C A0 K 1 e t /

d. A typical sketch is given here. We already have experience with the step response to a

linear, first order system. We know that

- the output changes immediately after the step

is introduced.

- the maximum slope appears when the step is

introduced

- the curve has a smooth (non-oscillatory

response)

- 63% of the change occurs when

t = (past the step)

- the final steady state is K(input)

C’A

Time

C’A0

Time

e. We should always investigate the accuracy of our mathematical models! We can

estimate the accuracy of the parameters used based on

Laboratory data used in developing the

constitutive model

Construction of equipment

Accuracy of measurements used to achieve

desired values

- Is the rate expression accurate

- uncertainty in k

V (cross sectional area)

V (level) and F (flow)

In addition, we should estimate the error introduced by the linearization. No error is

introduced if the process stays exactly at the initial steady state, and the errors generally

increase as the process deviates further from the initial steady state. Here, two methods

are suggested. (Remember, we do not seek highly accurate models – we seek simple,

approximate models for control design, which will be explained shortly.)

1. Evaluate the key parameters over the range of operation. We can evaluate the gain

(K) and the time constant () at different values over the range of operation. If these

parameters do not change much, the linearization would be deemed accurate.

2. Steady-state prediction. Compare the steady-state output values from the non-linear

model with steady-state output values from the linearized model (Kinput). This method

will check the gain only, not the time constant.

02/06/16

28

McMaster University

4.2

Controlling the Reactor Concentration by Feed Flow Rate: The reactor in

question 3.1 above is considered again in this question. Component A is pumped to the

reactor from the feed tank. The inlet concentration of A, CA0, is constant, and the feed

flow rate varies with time.

a.

b.

c.

d.

Develop the dynamic model to predict the concentration of A.

Linearize the equation and solve the linearized equation analytically for a step

change in the feed flow rate, F.

Sketch the dynamic behavior of the effluent concentration, CA(t).

Describe the equipment required to maintain the feed flow rate at a desired value.

F0

CA0

F1

V

CA

Figure 3.1

Motivation: Why are we interested in this model? Often, the feed composition

cannot be adjusted easily by mixing streams. Therefore, we sometimes adjust the feed

flow rate to achieve the desired reaction conversion. (We do not like to do this, because

we change both the production rate and the conversion when we adjust feed flow rate.)

a. We begin by applying our standard method for modelling.

a. Goal: Determine composition of A as a function of time.

Variable: CA in the reactor

System: The liquid in the reactor.

Balance: Component balance on A.

Accumulation

(1)

=

in

-

out

MWA VC A | t t VC A | t MWA t FCA0 FCA VkC 0A.5

+

generation

Divide by delta time and take the limit to obtain

02/06/16

29

McMaster University

(2)

V

dC A

F(C A 0 FC A ) VkC 0A.5

dt

Are we done? Let’s check the degrees of freedom.

DOF = 1 - 1 = 0

Yes!

b. Is the model linear? If we decide to solve the model numerically, we do not have to

linearize; in fact, the non-linear model would be more accurate. However, in this

problem we seek the insight obtained from the approximate, linear model.

We see that several terms are non-linear. In fact, when flow is a variable, we would

usually find terms (F)(variable), where “variable” is temperature, compositions, etc. The

following terms will be linearized by expanding the Taylor series.

(3)

FC A0 (FC A0 ) s Fs C' A0 C A0s F' higher order terms

(4)

FC A (FC A ) s Fs C' A C As F' higher order terms

(5)

C 0A.5 C 0A.5

s

0.5 C A0.5

C

s

A

C As higher order terms

Substituting the approximations, subtracting the initial steady state, and rearranging gives

the following.

(6)

dC' A

C' A KF'

dt

with

V

Fs 0.5VkC

0.5

As

K

(C A 0s C As )

Fs 0.5VkC As0.5

We can solve this equation for step change in flow rate by taking the Laplace transform,

substituting F’(s) = F/s, and taking the inverse Laplace transform. The result is given in

the following equation.

(7)

02/06/16

C' A (t) (F)K 1 e t /

30

McMaster University

c. The plot and qualitative properties are the same as for other first order systems.

- the output changes immediately after the step

is introduced.

- the maximum slope appears when the step is

introduced

- the curve has a smooth (non-oscillatory

response)

- 63% of the change occurs when

t = (past the step)

- the final steady state is K(input)

C’A

Time

F’

Time

Does this make sense? As we increase the feed flow, the “space time” in the reactor

decreases. (See Fogler (1999) or other textbook on reaction engineering for a refresher.)

When the space time decreases, the conversion decreases, and the concentration of

reactant increases. Yes, the model agrees with our qualitative understanding!

d. Equipment is required to control the flow is needed if we are to adjust the flow to

achieve the desired reactor operation, e.g., conversion. Any feedback controller requires

a sensor and a final element. (See Chapter 2.) The sensor could be any of the sensors

described in the Instrumentation Notes. The most common sensor in the process

industries is the orifice meter, which measures flow based on the pressure drop around an

orifice restriction in a pipe. The final element would be a control valve that can adjust

the restriction to flow.

Valve with

adjustable stem

position

Pump to supply

the “head” for

flow

P

Orifice

meter

02/06/16

31

McMaster University

4.3

Isothermal CSTR with two input changes: This question builds on the results

from tutorial Questions 3.1 and 3.2. Consider a CSTR with the following reaction

occurring in the reactor

AB

-rA = kCA0.5

Assuming 1) the reactor is isothermal, 2) the reactor is well mixed, 3) density of the reactor

content is constant, and 4) the reactor volume is constant.

a.

Derive the linearized model in deviation variables relating a change in C A0 on the

reactor concentration, CA.

b.

Derive the linearized model in deviation variables relating a change in F on the

reactor concentration, CA.

c.

Determine the transfer functions for the two models derived in parts a and b.

d.

Draw a block diagram relating CA0 and F to CA.

e.

The following input changes are applied to the CSTR:

1.

A step change in feed concentration, CA0, with step size CA0 at tC, and

2.

A step change in feed flow rate, F, with step size F at tF.> tC.

Without solving the equations, sketch the behavior of CA(t).

a/c. The model for the change in CA0 (with the subscript meaning the input change CA0). The

model for this response has been derived in previous tutorial question 3.1, and the results

are repeated in the following.

CA 0

dC' A

C' A K CA 0 C' A 0

dt

(1)

(C' A (s)) CA 0

with CA 0

K CA 0

C' A 0 (s)

CA 0 s 1

C' A (t ) C A0 K CA 0 1 e t / CA0

02/06/16

V

F 0.5VkC

0.5

As

transfer function

K CA 0

F

F 0.5VkC As0.5

(C A (s)) CA 0

K CA 0

C A 0 (s)

CA 0 s 1

32

McMaster University

b/c. The model for a change in F (with the subscript meaning the input change F) The model

for this response has been derived in previous tutorial question 3.2, and the results are

repeated in the following.

F

dC' A

C' A K F F'

dt

(2)

(C' A (s)) F

with F

V

Fs 0.5VkC

KF

F' (s)

Fs 1

C' A (t ) (F)K F 1 e t / F

0.5

As

transfer function

KF

(C A 0s C As )

Fs 0.5VkC As0.5

(C A (s)) F

KF

F(s)

Fs 1

c. The transfer functions are given in the results above.

Remember that a transfer function simply gives the relationship between the input and

output.

INPUT

TRANSFER

FUNCTION

OUTPUT

Since the system is linearized, we can add the output changes in C’A to determine the overall

affect.

(3)

(C' A (s)) (C' A (s)) CA 0 (C' A (s)) F

d. The block diagram is given in the figure.

Note that the primes (’) to designate deviation variables are not used in transfer

functions or block diagrams. This is because transfer functions and block

diagrams ALWAYS use deviation variables.

Remember that the block diagram is simply a picture of equations (1) to (3).

02/06/16

33

McMaster University

CA0(s)

(CA(s))CA0

KCA0/(CA0s+1)

+

F(s)

CA(s)

KF/(Fs+1)

(CA(s))F

e. We can sketch the shape of the response without knowing the numerical values of many

parameters because we understand dynamic systems. Let’s list some aspects of the

response that we know.

1.

2.

3.

4.

5.

KF is positive

KCA0 is positive

Both systems are first order

The two time constants are equal

Both systems are stable (time constants are positive)

The figure below was generated with 1) a positive step change in CA0 and after a long time, a

positive step change in F.

time

What would the plots look like with

a.

a positive change in CA0 and a negative in F?

b.

both changes introduced at the same time?

c.

A slow ramp introduced in CA0?

Can you think of other types of input changes and sketch the output concentration?

02/06/16

34

McMaster University

4.4

Let’s consider the usefulness of the transfer functions that we just derived. From the

transfer function CA(s)/CA0(s), answer the following questions.

a.

b.

Does a causal relationship exist?

What is the order of the system?

c.

Hint: How could the process gain help?

Hint: How many differential equations are in the

model?

Is the system stable?

Wow: we sure need to know if a process is

unstable!

d.

Could CA(t) exhibit oscillations

Question: Why would we like to know this?

from a step change in CA0?

e.

Would any of your answer change

Important: We can learn general types of

for any values of the parameters of behavior for some processes!

the model (F, V, k, etc.)?

a. A causal relationship exists if the transfer function is NOT zero. While this is not exactly correct, we

will test for the existence of a causal relationship by evaluating the steady-state gain.

K=0

no causal relationship

K0

causal relationship

We should also look at the magnitude of the gain.

The answer for CA(s)/CA0(s) is yes; a causal relationship exists!

Follow-up question: Can you think of a situation in which the steady-state gain is zero, but a causal

relationship exists?

b. The order of the system is the number of first order differential equations that relate the input to the

output.

One quick way to check this is to evaluate the highest power of “s” in the denominator of the transfer

function.

The answer for CA(s)/CA0(s) is one, or first order.

Follow-up question: Are the order of all input/output pairs the same for any processes? Hint: What is the

order of CB(s)/CA0(s) for the same reactor?

c. The system is stable if the output is bounded for a bounded input. (Any real input is bounded, but a ramp

could become infinite when we overlook the physical world, where valves open completely and mole

fractions are bounded between 0 and 1.)

02/06/16

35

McMaster University

We determine stability by evaluating sign of the exponent relating the variable to time. Recall that y = A e

–t

= A e –t/. The value of alpha is the root(s) of the denominator of the transfer function!

= 1/ > 0

stable

= 1/ 0

stable

The answer for CA(s)/CA0(s) is > 0; therefore, the system is stable.

Follow-up question: If one variable in a system is stable (unstable), must all other variables in the system

be stable (unstable)?

d. The function form of the time dependence of concentration is given in the following.

C' A (t ) C A0 K CA 0 1 e t / CA0

When the roots of the denominator of the transfer function are real, the system will be over damped

(or critically damped).

The answer for CA(s)/CA0(s) is no.

Follow-up question: If one variable in a system is overdamped (underdamped), must all other variables in

the system be overdamped (underdamped)?

e. We can determine possible types of behavior by looking at the range of (physically possible) values for

the parameters in a process. (We must assume that the model structure, i.e., the equations, is correct.)

The parameters in the model are all positive; none can change sign. For this and the equations for the gain

and time constant, we conclude that

The answer for CA(s)/CA0(s) is no, the qualitative features (causal, first order, stable) cannot change.

You can test your understanding by answering these questions for any other model in the course!

Now, you can apply your analysis skills to another process!

02/06/16

36

McMaster University

4.5

Process plants contain many interconnected units. (As we will see, a control loop contains many

interconnected elements as well.) Transfer functions and block diagrams help us combine individual

models to develop an overall model of interconnected elements.

Select some simple processes that you have studied and modelled in this course.

a.

Connect them is series.

b.

Derive an overall input-output model based on the individual models.

c.

Determine the gain, stability and damping.

d.

Sketch the response of the output variable to a step in the input variable.

a. Series process - As a sample problem, we will consider the heat exchanger and reactor series process in

the following figure. This is a common design that provides flexibility by enabling changes to the reactor

temperature. As we proceed in the course, we will see how to adjust the heating medium flow to achieve

the desired reactor operation using feedback control.

F

T0

CA0

F

CA0

T

CA

T

Fh

Heat exchanger

CST Reactor

In this example, the heating medium flow, Fh, (valve opening) is manipulated, and the concentration of

the reactant in the reactor, CA, is the output variable.

As we proceed in the course, we will see how to adjust the heating medium flow to achieve the desired

reactor operation using automatic feedback control.

Heat exchanger: The heat exchanger model is derived in the textbook Example 3.7, page 76. The results

of the modelling are summarized in the following, with the subscript “c” changed to “h”, because this

problem involves heating.

Energy balance: (with Cp Cv)

Vex C p

02/06/16

dT

FCp (T0 T) Q W

dt

37

McMaster University

Q UA (T (Thin Thout ) / 2)

with

and

UA

aFcb1

Fc aFcb / 2 h C ph

Linearized model:

ex

dT'

T' K pex Fc'

dt

with the subscript “ex” for exchanger.

Transfer function: (Taking the Laplace transform of the linearized model)

K pex

T (s)

G ex (s)

Fh (s) ex s 1

a first order system!

Non-isothermal CSTR: The basic model of the CSTR is given in textbook equations (3.75) and (3.76),

which represent the component material and energy balances. They are repeated below, with

typographical errors corrected here!

V

dC A

F(C A 0 C A ) Vk 0 e E / RT C A

dt

VC p

dT

FC p (T0 T) UA (T Tcin ) (H rxn )Vk 0 e E / RT C A

dt

These equations are linearized in Appendix C to give the following approximate model, with only input T 0

varying.

dC' A

a 11C' A a 12 T '

dt

dT'

a 21C' A a 22 T 'a 25 T ' 0

dt

We can take the Laplace transform of the linearized equations and combine them by eliminating the reactor

temperature, T’, to give the following transfer function.

a 25

C' A (s)

G r (s)

T' 0 (s) s 2 (a 11 a 22 )s (a 11a 22 a 12 a 21 )

02/06/16

a second order system

38

McMaster University

Note that the reactor is a second order system because the energy balance relates inlet temperature to

reactor temperature and the component material balance relates temperature to concentration, because of

the effect of temperature on reaction rate.

b. Combining the linearized models: The block diagram of this system is given in the following figure.

This is a series connection of two processes, a first order exchanger and a second order reactor, which gives

the overall third order transfer function given in the following equation.

K pex

a 25

C' A (s)

T' (s) C' A (s)

G ex (s)G r (s)

2

T' 0 (s) T' 0 (s) T' (s)

( ex s 1) s (a 11 a 22 )s (a 11a 22 a 12a 21 )

Note that heat exchanger and reactor are a third order system.

c. Model analysis –

Gain: The steady-state gain can be derived from this model by setting s=0. (Recall that this has meaning

only if the process is stable.) The gain in this system is none zero, as long as the chemical reaction depends

on temperature.

Damping: We cannot be sure that the roots of the denominator of the transfer function are real. If fact, the

analysis of the CSTR in textbook Appendix C shows that the dynamics can be either over or underdamped,

depending on the design and operating parameters.

Stability: We cannot be sure that the CSTR is stable, i.e., roots of the denominator of the transfer function

have negative real parts. If fact, the analysis of the CSTR in textbook Appendix C shows that the dynamics

can be either stable or unstable, depending on the design and operating parameters.

02/06/16

39

McMaster University

d.

Step response: Many different responses are possible for the CSTR, and only one case is sketched

here. Recall the dynamic response between T 0 and T1 is first order. Since we have copious experience

with this step response, it is not given in a sketch. An example of the response between T 0 and T3 are

given in the following figure. The plot is developed for an example without heat of reaction. In this

situation, the third order system is guaranteed to be stable and overdamped; as we expect, the response

has an “s-shaped” output response to a step input, with the reactant concentration decreasing in

response to an increase in heating fluid to the exchanger.

DYNAMIC SIMULATION

Reactant concentration

0

10

20

30

Time

40

50

60

0

10

20

30

Time

40

50

60

Heating fluid valve opening

02/06/16

40

McMaster University

Solutions for Tutorial 5

Dynamic Behavior of Typical Dynamic Systems

5.1

First order System: A model for a first order system is given in the following

equation.

(5.1.1)

dY

X in X out

dt

What conditions have to be satisfied for the system to be self-regulating?

A stable self-regulating system has an output variable that tends to a steady state

after the input variable has reached an altered steady-state value. The system

described in equation (5.1.1) will not necessarily be self-regulating.

If both Xin and Xout are independent of Y, the derivative of the output variable is

independent of the input variable. For example, the following condition could

occur.

dY

X in X out 5 2 3

dt

Since the derivative is a constant, the output variable would increase without

limit. Therefore, the system is non-self-regulating and is unstable.

Let’s look at a physical system that is

stable and self-regulatory. The level in

the tank is affected by the flow in to and

out of the tank. The overall material

balance has the form of equation (5.1.1)

and gives the following for a tank with

straight sides.

Level

Fin

Fout

dL

Fin Fout

dt

As the level increases, the flow in decreases, which is a stabilizing effect. Also,

as the level increases, the flow out increases, which is a stabilizing effect. This is

a self-regulating, first-order system.

Note that a self-regulating system is not guaranteed to behave well. For the level

example, a large increase in the flow in (due to an increase in the source pressure)

will cause the level to increase. The flow out will also increase, but not

necessarily enough to reach a constant level before the level overflows. We see

that the magnitude of a disturbance will influence whether the variables in a selfregulating system remain within acceptable limits.

02/06/16

41

McMaster University

We can draw two conclusions from Question 5.1.

1.

We seek to design processes without non-self-regulating variables.

(This is not always possible.)

2.

We must control non-self-regulating variables.

(This is possible; see Chapter 18 for details.)

5.2 Second and higher order systems can be over or under damped. Which is more

likely to occur in chemical processes?

X1

X2

X3

XN+1

…...

Most chemical processes are interconnections of first-order systems, resulting

from material and energy balances. These interconnections involve interacting

and non-interacting first order systems, which are overdamped. Therefore, the

vast majority of chemical process - without feedback control - are overdamped.

However, we will see that the application of feedback control to these processes

can, and often does, result in underdamped systems. So, even though models

developed in Chapters 3-5 are overdamped, engineers must deal with

underdamped behavior.

Most chemical process without control are overdamped.

5.3 You are working in a plant and need to estimate the delay for flow through a pipe.

How can you evaluate the dead time?

There are two obvious ways.

1.

Measure the length of the pipe (L). Then, determine the velocity of the

fluid in the pipe (v). For turbulent flow (with a flat velocity profile), the dead

time would be = L/v.

2.

Perhaps, the pipe is underground, and

we do not know the path taken. We can

perform an experiment to evaluate dead time.

We can introduce a step change of a tracer

component with a small flow rate, so that the

tracer does not modify the process behavior.

The dead time is the time between the

introduction of the tracer at the inlet to the

02/06/16

Xout

= dead time

Xin

time

42

McMaster University

pipe and the first time that the tracer appeared at the pipe outlet.

5.4 Are the pressures in the vessels in Figure 5.4 self-regulating or non-self-regulating?

The fluid is a gas, and the feed and exhaust pressures are constant. In answering this

question, think about the response of the system to a change in the percent opening of the

first valve.

Qualitative analysis: We begin by recognizing that the flow rate through a pipevalve combination depends on the pressure difference (Pin - Pout), assuming that

the flow rate is sub-sonic. When the first valve opening is increased, the flow into

the first vessel increases. The increase in vessel pressure will offer greater

resistance to the flow in and a greater driving force for the flow out. Therefore,

the vessel pressure is self-regulating.

Modelling: The mass balance for the gas in a vessel is given by the following.

d (mass )

in Fin out Fout inCv (vi 1 ) Pi 1 Pi outCv (vi ) Pi Pi 1

dt

Also, the mass in the vessel can be related to the pressure by the ideal gas law. If

the temperature is assumed constant, the derivative of mass is simply a constant

times the derivative of pressure.

PV ( MW )

RT

dP

RT d ( mass )

dt V ( MW )

dt

mass

Substituting, yields the expression that demonstrates the reliance of the pressure

derivative on the pressure

V ( MW ) dPi

inC v (vi 1 ) Pi 1 Pi outC v (vi ) Pi Pi 1

RT

dt

Therefore, the pressure in each vessel is self-regulating.

Note that the process is an interacting series of first-order systems.

02/06/16

43

McMaster University

5.5 You have obtained the graph in Figure 5.5 by making a step to a valve opening and

observing the dynamic response of the temperature. From the results of this experiment,

describe the physical process (order, dead time, etc.)

Change in Measured

Output (K)

3

2

1

0

-1

0

10

20

30

40

50

60

0

10

20

30

Time (min)

40

50

60

Change in valve opeining (%)

3

2

1

0

-1

Figure 5.5

The experimental data gives us valuable information about the process. In fact,

we will see in the upcoming topics that this type of information is exactly what is

used for designing control systems. However, the data shows the “input-output”

behavior only, and it does not provide sufficient information to enable us to

reconstruct the complete process structure.

Let’s see what we can conclude about the process.

02/06/16

The output variable attains steady state after a step change in the input.

We conclude that the process is stable and self-regulatory.

From the shape of the output to a step, which does not oscillate, we

conclude that the process is overdamped.

The output does not change perceptibly when the input variable is first

changed. This indicates a “dead time”. However, we cannot be sure about

the process structure that would yield this behavior. Recall that a series of

first-order processes has a step response with essentially no change for an

initial period; we call this “apparent dead time”. So, we conclude that the

process has either an actual time delay, e.g., a pipe, or a higher order,

overdamped process. Naturally, a combination of dead time and time

constants is also possible.

44

McMaster University

Since the output has no “inverse response” we conclude that no negative

zeros in the transfer function. Since the output does not overshoot its final

value, we conclude that positive zeros are not greater than the poles. In

short, the step response is smooth and monotonic in spite of any parallel

paths that might exist.

We can determine the steady-state gain from the graph, which is

Kp = (output)/ (input) 1.0 K/%open

We can determine the “speed” of the response, which we characterize

using the 63% time of the response.

t 63%

(

i

i ) 15 .0 min

i

As we see, we can learn a lot from the data, but we cannot describe the

process exactly.

5.6 We have models for several processes which we decide to connect in the process

structure shown in Figure 5.6. The input variable experiences a step change of 3.5 %

open. Describe the dynamic behavior based on qualitative and semi-quantitative

analysis, that is, do not simulate the process.

Tf

TR

A2

A-2

CP

fuel

v

v(s)

Tf(s)

G1(s)

Valve

opening

Reactor feed

temperature

TR(s)

G2(s)

Reactor

temperature

CP(s)

G3(s)

Product

Composition

A2(s)

G4(s)

Product

Composition

Measurement

Figure 5.6

02/06/16

45

McMaster University

The models for the system are given in the following.

1.2e 1s

5s 1

0.80 e 0.5s

G2 ( s)

(2 s 1)

G1 ( s)

G3 ( s )

1.5e 2 s

(3s 1)( 5s 1)

G4 ( s)

1.0e 0.5s

(1s 1)( 2 s 1)

We can determine a great deal about the dynamic response.

The processes are in series; therefore the overall transfer function is the

product of the individual process transfer functions.

Each individual process is satble (negative poles), so the series is stable.

The steady-state gain of the series is the product of the individual gains.

Kp = (1.2)(0.80)(1.5)(1.0) = 1.44 mole fraction/%open

From this result, we can calculate the steady-state change in the product

composition for a 3.5% change in the valve opening.

A1 = 1.44*3.5 = 5.04 mole fraction

The shape of the dynamic response can be determined in a qualitative

way. First, some dead time will exist. Second, the system is sixth order

and overdamped, because the roots of the denominator are all real. (Note

they can be factored.)

The “speed” of the process can be estimated from the 63% time of the step

response, which is the sum of the dead times and time constants of the

elements in the series.

t63% (1 0.5 2 2 3 5 0.5 1 2) 17 minutes

We could determine an approximate first-order with dead time model using the

moments method in Appendix D, but this effort is not usually warranted. We

already have a good understanding of the response, and we can simulate it easily

if more precise results are required.

Reaction: A B

5.7 The recycle process shown in

Figure 5.7 is to be analyzed in this

question.

Rate: -rA = kCA

Product (pure B)

Ff

FP

feed

Recycle (pure A)

Figure 5.7

02/06/16

Fr

Any inerts

appear here

after

separation

46

McMaster University

Information:

The initial steady-state reactor conversion in the isothermal, constant-volume

CSTR is 50%. Therefore, Ff = FR.

The separator has first order dynamics.

a.

Determine the dynamic behavior of the concentration of an inert that enters in the

fresh feed. The inert exits the separation unit in the bottoms stream that is the

recycle; none leaves in the product stream. (To simplify the analysis, assume that

the concentration of the inert is initially small, so that the chemical reaction and

the total flow rates are not affected by changes in the inert concentration.)

b.

Determine the response of the concentration of the reactant to a change in the

reactor temperature that reduces the reaction rate by 10%, i.e., from 50% to 45%.

a.

Qualitative analysis: We note inert material enters with the fresh feed and

does not exit the process. Therefore, inert must accumulate in the process,

leading to an increasing concentration. Thus, the inert composition is a non-selfregulatory variable. While the composition is initially small and might not affect

the process, it will ultimately increase sufficiently to affect the reaction and

separation.

We know from our Material and Energy Balances course that a recycle system

should have a purge to prevent an excessive concentration of inert. Naturally, the

purge can be costly due to loss of material; therefore, the purge rate is set to

achieve the acceptable inert concentration.

Quantitative analysis: For the inert component, component balances are required.

Note that we take advantage of the assumption that the total flows and reaction

rate are not affected, which is valid when the inert concentration is very small at

the initial part of the transient. The following balances can be derived.

Reactor feed concentration (mass fraction) (essentially steady-state mixing):

x fi ( s ) 0.50 x freshi ( s ) 0.50 x recyclei ( s )

Reactor outlet concentration (essentially, a mixing tank):

x reactori ( s)

1

Rs 1

x fi ( s)

Recycle concentration (first order dynamics given in statement)

02/06/16

47

McMaster University

x recyclei ( s)

2

x reactori ( s)

Ss 1

These equations can be combined to give a concentration response to a change in

the fresh feed concentration. We will select the reactor feed concentration. We

solve the linear equations simultaneously, by combining and eliminating variables

(using methods introduced in Chapter 4).

x fi ( s ) 0.50 x freshi ( s ) 0.50 x recyclei ( s )

0.50 x freshi ( s ) 0.50

2

x reactori ( s )

Ss 1

0.50 x freshi ( s ) 0.50

2

1

x fi ( s )

Ss 1 Rs 1

Solve for xfi(s),

2

1

x fi ( s) 1 0.50

0.50 x freshi ( s )

s

1