Reduction of Concentration Polarization by Simultaneous Oscillation

advertisement

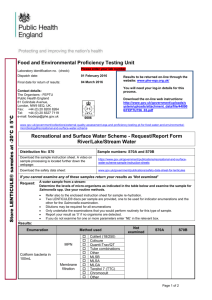

Reduction of Concentration Polarization by Simultaneous Oscillation of Suspension and Permeate in Membrane Crossflow Filtration Bolaji Olayiwola and Peter Walzel Technische Universität Dortmund, Chair of Mechanical Process Engineering, Faculty of Biochemical and Chemical Engineering, Emil-Figge-Strasse 68, 44227 Dortmund Abstract Crossflow filtration is a solid-liquid separation process with applications in the pharmaceutical, environmental and petrochemical industries. In contrast to the dead-end filtration, the suspension to be filtered flows along the filter medium in order to limit the growth of deposited cake and increase permeate flux. This effect is controlled by the crossflow velocity. High velocities entail thinner deposit layer and vice versa but this leads to increased pressure drop and consequently high energy consumption. Concentration polarization and fouling (including deposition, pore constriction, particle intrusion and macromolecular adsorption in the pores of the secondary cake and membrane) are important factors that limit its performance. Several techniques have been adopted to reduce concentration polarization and fouling in membrane processes. These include oscillation of device/ filter plate, high frequency backwashing of the membrane/ medium by reversal of the transmembrane pressure and use of continuous pressure filter with rotating discs. A summary of several other methods that have been adopted is presented in [1]. For the purpose of our study, attention is given to the hydrodynamic method, i.e. flow pulsation. A considerable number of research have been carried out to improve process performance in a crossflow filtration by superimposition of oscillation on the suspension to be separated. In all, increased but declining filtrate flux over time was reported. A consideration of the dynamic pressure along the length of the medium for this system reveals pressure fluctuation during one oscillation cycle. This results in locally different pressure difference between the suspensions and the filtrate. As a consequence, filter pores close to the inlet are predominantly blocked during the forward stroke and the filtrate may penetrate into the pores during the backward stroke. Hence, this can be considered to be responsible for the continuous decline of the filtrate flux over time. When the suspension and the permeate are simultaneously oscillated in-phase, the differential pressure across the filter medium is independent of the phase of oscillation and uniform pressure difference could be maintained over the length of the membrane [2]. In this work, the filter medium used for the experiment is Ultipor Nylon 6.6 media of Pall GmbH Microelectronics, Germany. The mean pore size of the membrane is 0.2 m. Bakers’ yeast suspension with particle size of 4.7m and 1% solid volume concentration was filtered. Reynolds number considered is Re < 1000. Better performance of the process was acquired and constant permeate flux was maintained over a long period of time. Flow visualization reveals no significant particle deposition on the membrane. These are related partly to the lift force on the particles and partly to depolarization as a result of the backmixing of particle layer due to flow reversal. Reference [3] Belfort, G, Davis, R.H and Zydney, A. L., 1994, “The behaviour of suspensions and macromolecular solutions in crossflow microfiltration”, J. Mem. Sci., 96, 1-58. [2] Olayiwola, B. and Walzel, P., 2008, “Flow Manipulation for Performance Enhancement in Crossflow Filtration”, Proceedings of 10th World Filtration Congress, Leipzig, Germany, II-431.