Industrial spray application

advertisement

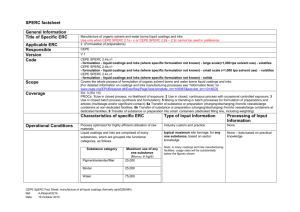

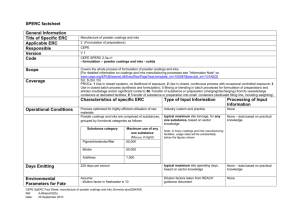

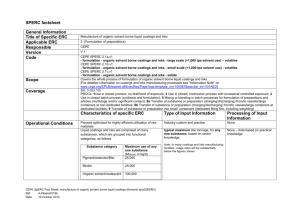

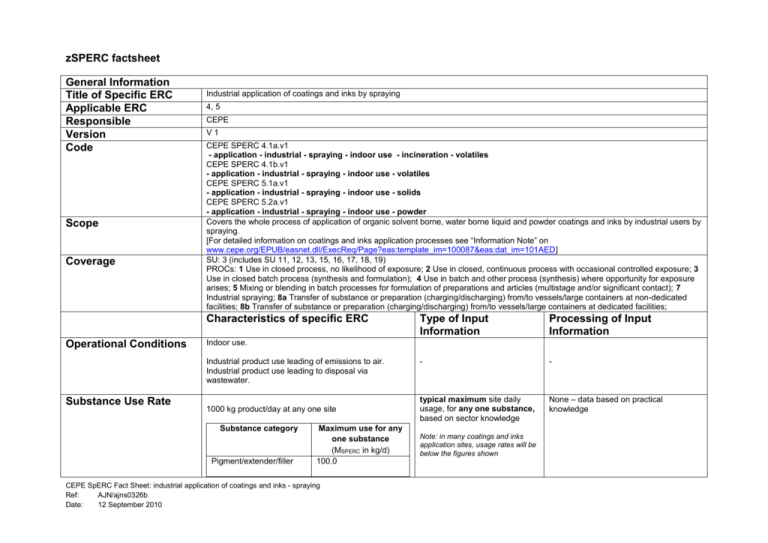

zSPERC factsheet General Information Title of Specific ERC Applicable ERC Responsible Version Code Scope Coverage Industrial application of coatings and inks by spraying 4, 5 CEPE V1 CEPE SPERC 4.1a.v1 - application - industrial - spraying - indoor use - incineration - volatiles CEPE SPERC 4.1b.v1 - application - industrial - spraying - indoor use - volatiles CEPE SPERC 5.1a.v1 - application - industrial - spraying - indoor use - solids CEPE SPERC 5.2a.v1 - application - industrial - spraying - indoor use - powder Covers the whole process of application of organic solvent borne, water borne liquid and powder coatings and inks by industrial users by spraying. [For detailed information on coatings and inks application processes see “Information Note” on www.cepe.org/EPUB/easnet.dll/ExecReq/Page?eas:template_im=100087&eas:dat_im=101AED] SU: 3 (includes SU 11, 12, 13, 15, 16, 17, 18, 19) PROCs: 1 Use in closed process, no likelihood of exposure; 2 Use in closed, continuous process with occasional controlled exposure; 3 Use in closed batch process (synthesis and formulation); 4 Use in batch and other process (synthesis) where opportunity for exposure arises; 5 Mixing or blending in batch processes for formulation of preparations and articles (multistage and/or significant contact); 7 Industrial spraying; 8a Transfer of substance or preparation (charging/discharging) from/to vessels/large containers at non-dedicated facilities; 8b Transfer of substance or preparation (charging/discharging) from/to vessels/large containers at dedicated facilities; Characteristics of specific ERC Operational Conditions Processing of Input Information - - typical maximum site daily usage, for any one substance, based on sector knowledge None – data based on practical knowledge Indoor use. Industrial product use leading of emissions to air. Industrial product use leading to disposal via wastewater. Substance Use Rate Type of Input Information 1000 kg product/day at any one site Substance category Pigment/extender/filler Maximum use for any one substance (MSPERC in kg/d) 100.0 CEPE SpERC Fact Sheet: industrial application of coatings and inks - spraying Ref: AJN/ajns0326b Date: 12 September 2010 Note: in many coatings and inks application sites, usage rates will be below the figures shown Binder 100.0 Water 350.0 Organic solvent/coalescent 450.0 Additives 5.0 225 d/y Days Emitting Environmental Parameters for Fate Calculation Local freshwater dilution factor: 10 Local marine dilution factor: 100 Receiving surface water flow is 18,000 m3/d Industry knowledge None REACH guidance defaults None Characteristics of Specific ERC Emission Fractions (in application and drying) Air a) Total volatile substances: Emissions to air of organic solvents from the industrial application of coatings and inks are regulated by the Solvent Emissions Directive (1999/13/EC). Emission fraction is dependent on - the sector concerned - the annual solvent usage (tonnage) - the emission control option selected These are found in Annexes IIA and IIB of the directive CEPE SPERC 4.1a.v1: 0.008 Justification i) Emission limits from The Solvent Emissions Directive (1999/13/EC) [http://eurlex.europa.eu/LexUriServ/LexUriServ.do? uri=OJ:L:1999:085:0001:0022:EN:PDF and corrigendum] For a coating film to form, the volatile phase of organic solvent borne and water borne coatings must evaporate into the atmosphere. 80% solvent inputs emitted through Incinerator with efficiency 99% No OECD Coatings ESD data – industry data CEPE SpERC Fact Sheet: industrial application of coatings and inks - spraying Ref: AJN/ajns0326b Date: 12 September 2010 CEPE SPERC 4.1b.v1: 0.98 For a coating film to form, the volatile phase of organic solvent borne and water borne coatings must evaporate into the atmosphere. OECD Coatings ESD CEPE SPERC 5.1a.v1: 0.02 CEPE SPERC 5.2a.v1: 0.02 A proportion of the solid phase will be contained in overspray. OECD ESD Wastewater Soil Appropriate Risk Management Measures (RMM) that may be used to achieve required emission reduction CEPE SPERC 4.1a.v1: 0.02 CEPE SPERC 4.1b.v1: 0.02 A proportion of the liquid phase will be present in spray booth scrubber water. CEPE SPERC 5.1a.v1: 0.0 CEPE SPERC 5.2a.v1: 0.0 There is no emission to water during application and drying CEPE SPERC 4.1a.v1: 0.0 CEPE SPERC 4.1b.v1: 0.0 CEPE SPERC 5.1a.v1: 0.0 CEPE SPERC 5.2a.v1: 0.0 There is no deposition to soil from these application processes. Type of RMM Air: Note: no PNEC/no RCR CEPE SPERC 4.1a.v1: Thermal oxidiser (incinerator) CEPE SPERC 4.1b.v1 and CEPE SPERC 5.1a.v1: Wet scrubber or filtration CEPE SPERC 5.2a.v1: Cyclone and/or filter Wastewater: municipal STP Soil: Not applicable Typical Efficiency 99% 95% 95% - Narrative Description of, and justification for, specific ERC CEPE SpERC Fact Sheet: industrial application of coatings and inks - spraying Ref: AJN/ajns0326b Date: 12 September 2010 Safe Use Communication in eSDS The REACH registrant establishes a set of standard conditions of safe use for a substance for wide dispersive use in the application of coatings by consumers by adopting the conditions specified in this SPERC. This information is documented in the Chemical Safety Report and communicated in the extended Safety Data Sheet. All other parameters underlying a substance exposure scenario based on this SPERC are implicitly referred to via the reference to this SPERC. Scaling CEPE SpERC Fact Sheet: industrial application of coatings and inks - spraying Ref: AJN/ajns0326b Date: 12 September 2010