Transit Bus Engine Power Simulation, Modal Emissions Modeling

advertisement

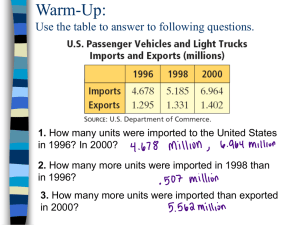

Prepared for the 98th AWMA (2005) Meeting by Yoon, S., Li, H., Jun, J., Guensler, R., and Rodgers, M. Transit Bus Engine Power Simulation: Comparison of Speed-Acceleration-Road Grade Matrices to Second-bySecond Speed, Acceleration, and Road Grade Data Paper # 563 Seungju Yoon, Hainan Li, Jungwook Jun, Randall L. Guensler, and Michael O. Rodgers School of Civil and Environmental Engineering, Georgia Institute of Technology 790 Atlantic Drive Atlanta, GA 30332-0355 ABSTRACT The Georgia Institute of Technology (Georgia Tech) School of Civil and Environmental Engineering has been developing speed-acceleration-road grade matrices for use in modal activity-based emissions models. These new modal emission rate models for heavy-duty transit buses predict emissions as a function of engine power demand for given transit bus activities, vehicle hours of travel, and baseline grams/brake-horsepower-hour emissions rates. Such models can predict the second-by-second emissions from a transit vehicle, given the vehicle characteristics, infrastructure parameters, and onroad operating conditions. However, one concern modelers facing is the extent to which the use of more aggregated speed/acceleration parameters (rather than the second-by-second parameters) will affect model predictions. Hence, the goal of this evaluation is to determine the potential effect that the use of speed-acceleration-road grade probability distribution functions will affect predictions used in emissions inventory development and microscale air quality impact assessment. The research team developed a transit bus engine power demand simulator (TB-EPDS), which estimates transit bus power demand for given speed, acceleration, and road grade conditions. Speed-acceleration-road grade matrices were developed from speed and location data obtained with a Georgia Tech Trip Data Collector (an onboard computer with GPS receiver, data storage, and wireless communication device). The Georgia Tech Trip Data Collector was installed on two transit buses operated on numerous routes by Metropolitan Atlanta Rapid Transit Authority in Atlanta, Georgia. The TB-EPDS was used to estimate transit bus engine power demand using second-by-second data as well as using speed-acceleration-road grade matrices for each link and for the entire bus route. The researchers conclude that speed-acceleration-road grade matrices at the link level or the route level are both acceptable for regional inventory development. However, for microscale air quality impact analysis, link-based matrices will be required. 1 Prepared for the 98th AWMA (2005) Meeting by Yoon, S., Li, H., Jun, J., Guensler, R., and Rodgers, M. INTRODUCTION Vehicle modal activity-based emissions models associated with baseline emissions rates, engine power demand, and vehicle hours of travel are suggested as next generation mobile source emissions models. That is because the modal activity based emissions models can overcome shortfalls that current average speed cycle-based mobile source emissions models can not properly reflect emissions rates resulting from various modal vehicle activities such as acceleration, deceleration, cruse, and motoring/idling on a given road geometry and environmental condition (1). Currently, the U.S. Environmental Protection Agency (EPA) is developing a new generation mobile source emissions model (Motor Vehicle Emission Simulator, MOVES) based on vehicle specific horsepower requirement that is a function of speed, acceleration, and road grade (2). However, collecting speed and acceleration data on various roads during different time periods, and simulating emissions with modal emissions models will require extensive data collection effort and resources. To reduce the data collection effort and resources and to use in modal activity-based mobile source emissions models, the Georgia Institute of Technology (Georgia Tech) research team recently developed transit bus speed-acceleration matrices using speed and location data obtained with a Georgia Tech Trip Data Collector having a global positioning system (GPS) receiver (3). However, emissions rates estimated using speed-acceleration matrices will differ from emissions rates based upon actual second-by-second operating data because engine power demand, which is a linear function of emissions rate, increases non-linearly as speed and speed*acceleration increase. That is, median or mean speed and acceleration in a speed-acceleration matrix bin does not properly represent the nonlinear relationship between engine power demand and speed or speed*acceleration. To investigate the potential overestimation or underestimation of emissions estimated using speed-acceleration matrices incorporated with road grade, the research team has developed a transit bus engine power demand simulator (TB-EPDS) that estimates engine power demand for transit buses with both speed-acceleration-road grade matrices and actual second-by-second transit bus speed, acceleration, and road grade. The TB-EPDS consists of a tractive power demand module and an auxiliary power demand module. The tractive power demand module estimates engine power demand for a transit bus to overcome resistance forces (excluding auxiliary power demand) while in motion. The auxiliary power demand module estimates engine power demand for bus accessories such as lights, pumps, and fans. When tractive power demand is positive, the tractive power demand and the auxiliary power demand are added to estimate total engine power demand. When tractive power demand is zero or negative, the transit bus is idling or motoring (absorbing power during deceleration). Under these conditions, only auxiliary power demand was used in the estimation of total engine power demand (research is currently underway to examine emission rates under motoring conditions). Three speedacceleration-road grade matrices for the entire bus route and for each road link on the route were created by using speed and location data obtained from a transit bus running on the bus route 55 operated by Metro Atlanta Rapid Transit Authority (MARTA) in Atlanta, 2 Prepared for the 98th AWMA (2005) Meeting by Yoon, S., Li, H., Jun, J., Guensler, R., and Rodgers, M. Georgia. Matrices with 3, 5, and 10 miles per hour (mph) speed bin intervals, 1 mph/s acceleration bin intervals, and 0.5 degree (1.1%) road grade bin intervals were prepared from the data. Total transit bus engine power demand estimated with those matrices was compared to total power demand estimated with individual second-by-second speed, acceleration, and road grade. Total power demand on the entire bus route and total power demand on road links were compared with individual speed, acceleration, and road on road links. DATA SCREENING AND MATRIX GENERATION Researchers monitored the speed and location data for two transit buses using the Georgia Tech Trip Data Collector. These buses were monitored for seven months as they operated on more than 20 different MARTA bus routes. Researchers determined that bus activity (speed and acceleration) on the transit route significantly differed from other bus activities, such as driving between the garage and the transit route and extended idling that occurs at garages and bus/rail transfer points. So, only speed data long regular bus service routes during weekdays, which were acquired under valid global positioning system (GPS) operation conditions, were selected for the generation of speed-acceleration-road grade matrices by roadway facility type (arterial or local road). In this paper, data from bus route 55 (121,178 individual speed readings with valid GPS operation) were analyzed. GIS Data Screening and Map-Matching The GPS antenna connected to the Georgia Tech Trip Data Collector was installed on the roof of each transit bus to minimize satellite signal interference from buildings and tree canopies. This allowed that the GPS antenna to receive signals from as many satellites as possible. To obtain reliable transit bus speed and location data, data are only used when the GPS receiver receives a minimum of five satellite signals at the same time (4) and the position dilution of precision (PDOP) value, which is the measure of current satellite geometry, is less than or equal to six. The lower the PDOP value indicates the more accurate GPS positions to get satellite signals. Bus position data obtained with the GPS receiver generally do not fall on the center of the GIS digital road links because both the GPS location data and the GIS road links have positional errors comparing to real-world geometric locations. However, approximately 95% of GPS data fall within 5 meters of the actual onroad position (5). The research team developed a map-matching algorithm, which locates individual bus position data on the center of GIS digital road links and allows bus position data obtaining road link characteristics from GIS road links. Estimation of Acceleration Rates with Speed Data To estimate transit bus acceleration rates with valid speed data, the researchers selected only speed data on regular bus service routes with reliable GPS operations during weekdays. Because some second-by-second speed data are eliminated due to weak 3 Prepared for the 98th AWMA (2005) Meeting by Yoon, S., Li, H., Jun, J., Guensler, R., and Rodgers, M. satellite signals, direct calculation of acceleration from point data could result in errors if data are not processed carefully. The first and the last speed and acceleration data in a continuous data block were discarded after acceleration calculation. For the better accuracy and to reduce acceleration calculation errors, the central difference numerical method was used (6, 7). The central difference numerical method, which adopts two points next to a center point, better reflects the acceleration for the equally time spaced speed data. This method yielded second-by-second data for both speed and acceleration that could be used directly, or aggregated to speed/acceleration matrices. GIS Spatial Analysis Through the spatial analysis in Geographic Information System (GIS), road grade for each individual bus position was estimated. Because bus position data only have X- and Ycoordinates, elevation for each bus position datum was estimated by the interpolation with the Georgia State Digital Elevation Model (DEM) in 1:24,000-scale, which was downloaded from Georgia Department of Transportation (GDOT) GIS clearinghouse (8). After interpolating bus position data into the DEM, two-dimensional (with X- and Ycoordinates) and three-dimensional (with X- and Y-coordinates and elevation) distances between adjacent and time consecutive two bus positions were estimated. Then, road grade between two positions in degree were calculated with distances. To avoid GIS road grade calculation errors, road grade greater than +5.4 degree (12%) or less than -5.4 degree (-12%) were suppressed to +5.4 or -5.4. Grade measurement work in Atlanta is ongoing so that future modeling can use measured road grade values and properly reflect cut and fill sections for major facilities. Speed-Acceleration-Road Grade Matrices Before creating speed-acceleration-road grade matrices, speed bin break points were evaluated with 790,037 GPS and vehicle speed sensor (VSS) paired data obtained from five passenger vehicles operating in Atlanta, GA. Based upon analyses of these data, the research team developed the following speed bins (mph): 0 to 2.5, 2.5 to 5, 5 to 10, 10 to 70 in 10mph increments, and over 70mph. In this application, only GPS speed data were employed (no connection was included to the bus engine computer, which delivers better speed readings). Field research indicated that GPS speed data less than 5 mph is subject to significant speed error (VSS speed – GPS speed) and variance. However, at higher speed bins, the magnitude of error significantly decreased and narrowed to a ±5% error range (3). Therefore, for this study, speed data in the 0 to 2.5 and 2.5 to 5mph speed bins were aggregated into a single bin for zero miles per hour in speed. This aggregation can cause errors in engine power demand simulation because engine power demand at the low speed will be underestimated. Uncertainty from this aggregation can be solved if valid speed data are obtained at the low speed. Currently, the research team is working on improving speed and location data at the low speed and solving the uncertainty of speed data aggregation. 4 Prepared for the 98th AWMA (2005) Meeting by Yoon, S., Li, H., Jun, J., Guensler, R., and Rodgers, M. For the entire bus route, three sets of speed-acceleration-road grade matrices were created with three different speed bin increments, i.e., 3, 5, and 10 mph for bus speed greater than 5 mph. Bus speed less than or equal to 5 mph was aggregated into 0 mph speed bin, and bus speed greater than 55 mph was aggregated into 55mph speed bin. Acceleration rates ranged from –10.5mph/s to +10.5mph/s with 1mph/s bin increment. Acceleration rates less than -10.5 or +10.5 mph/s were aggregated into -10.5 or +10.5mph/s acceleration bin. Acceleration rates in between -0.5 and +0.5mph/s were aggregated into 0mph/s acceleration bin and considered 0mph/s in acceleration. Road grade bins ranged from 3.25 degree (-7.2%) to +3.25 degree (+7.2%) with 0.5 degree (1.1%) bin increment. Road grade less than -3.25 or greater than +3.25 degree was aggregated into the -3.25 or +3.25 degree road grade bin, respectively. Road grades between -0.25 and +0.25 degrees were aggregated into 0 degree road grade bin (assumed level grade). Cells in speedacceleration-road grade matrices were filled with activity frequencies for corresponding speed, acceleration, and road grade bins. Because speed and acceleration patterns on bus service start and end links were significantly different from the other links, these two links were excluded at the generation of route-based speed-acceleration-road grade matrices (Figure 1). Figure 1: The Bus Route 55 and GPS Position Distributions 5 Prepared for the 98th AWMA (2005) Meeting by Yoon, S., Li, H., Jun, J., Guensler, R., and Rodgers, M. Link-based speed-acceleration-road grade matrices were also created with the same methods used for route-based matrices. Transit bus engine power demand for each segment, which was estimated with route-based speed-acceleration-road grade matrices as well as link-based matrices, was compared with aggregated engine power demand with individual speed, acceleration, and road for each link. TRANSIT BUS ENGINE POWER DEMAND SIMULATOR The transit bus engine power demand simulator (TB-EPDS) estimates transit bus engine power demand using bus characteristics (such as frontal area and frontal area shape), bus speed and acceleration, road geometric parameters (such as road grade, facility types, surface material types), and power demand from transit bus accessories (9). While continuous auxiliary power demand can be determined based on season (summer or winter), time of day (day or night), and equipment duty cycle (10), tractive engine power demand (excluding auxiliary power demand) can be estimated with acceleration force, rolling resistance, gravitational force, aerodynamic drag, and rotational inertial loss. Total engine power demand, which is the combination of tractive engine power and auxiliary power demands, is expressed in the Equation 1. PV ,a ,W ,l [( V W ) * (( a) FR FW FD FI )]V ,a ,W ,l AP 550 g (Equation 1) Where: P is the total engine power demand (bhp) V is the vehicle speed (ft/s) a is the vehicle acceleration (ft/s2) W is the actual vehicle weight (lbf) l is the road grade (degree) g is the gravitational acceleration (32.2 ft/s2) FR is the rolling resistance force (lbf) FW is the gravitational weight force (lbf) FD is the aerodynamic drag force (lbf) FI is the drivetrain rotational inertial loss (lbf) AP is the auxiliary power demand (bhp) 550 is the conversion factor to bhp Acceleration Force Acceleration force is a function of the bus weight, linear bus acceleration rate, and the gravitational acceleration force, and is a component in the estimation of bus power demand for a given driving condition. By definition, a vehicle can only accelerate in a linear direction when there is available tractive force at the wheels. Hence, the acceleration force is the remaining tractive force at the wheels after the vehicle has overcome all other resistance forces and delivered any required auxiliary power (FR + FW + FD + FI + AP). In 6 Prepared for the 98th AWMA (2005) Meeting by Yoon, S., Li, H., Jun, J., Guensler, R., and Rodgers, M. the TB-EPDS, transit bus weight of 37,000 pounds was used. This weight is a median bus weight (halfway between empty weight and gross vehicle weight rating). Rolling Resistance Force (FR) Rolling resistance force is the sum of the force required to overcome the combined friction resistance at the tires. Rolling resistance, which is a function of tire size and type, pavement type, temperature, vehicle weight, and vehicle speed, is caused by contact friction, the tires’ resistance to deformation, aerodynamic drag at the tire, etc. The force required to overcome rolling resistance can be expressed with rolling resistance coefficient, bus weight, and road grade (9). FR Cr *W * cos( ) (Equation 2) Where: Cr is the rolling resistance coefficient θ is the road grade (degree) In the TB-EPDS, an empirical equation of “ 0.0041 0.000041* FPS * SC ”, which was suggested by SAE (11), was used for the rolling resistance coefficient estimation. Where the FPS is the bus speed (ft/s) and the SC is the road surface coefficient. In the TB-EPDS, the road surface coefficient of 1.5 was used for the worn asphalt surface (11). Gravitational Weight Force (FW) The gravitational force components account for the effect of gravity on vehicle weight when the vehicle is operating on a grade. The grade angle is positive on uphill grades (generating a positive resistance) and negative on downgrades (creating a negative resistance). FW W sin( ) (Equation 3) FW and θ has a straightforward linear relationship to the gravitational weight force. That means that the gravitational weight force increase on a positive grade exactly cancels the gravitational weight force decrease on the same negative grade. However, the linear relationship can not be linearly applied to the relationship between FW and transit bus engine power demand. This is because speed and acceleration patterns on the positive grade are significantly different on the same negative grade (7) Aerodynamic Drag Force (FD) As a vehicle moves forward through the atmosphere, drag forces are created at the interface of the front of the vehicle and by the vacuum generated at the tail of the vehicle. In fact, the flow of the air around the vehicle creates a very complex set of forces providing both resistance to forward motion and vehicle lift. The sum of the drag forces is typically 7 Prepared for the 98th AWMA (2005) Meeting by Yoon, S., Li, H., Jun, J., Guensler, R., and Rodgers, M. aerodynamic drag, which is a function of air density, aerodynamic drag coefficient, vehicle frontal area, and effective vehicle velocity. FD ( 2g ) Cd A f Ve 2 (Equation 4) Where: ρ is the air density (lb/ft3) Cd is the aerodynamic drag coefficient Af is the bus frontal area (ft2) Ve is the effective bus velocity (ft/sec) In the TB-EPDS, the bus frontal area of 80 square feet (ft2) (11) and the aerodynamic drag coefficient of 1.17 were used (13). Effective vehicle velocity (Ve) is the sum of vehicle speed and wind speed, where wind speed is positive if it blows toward the vehicle (headwind) and negative if it blows in the direction of travel (tailwind). Given the nature of the nonlinear relationship between effective velocity and aerodynamic drag, using the atmospheric wind speed of zero will introduce a bias into the predicted effect on engine power demand. However, effective vehicle velocity can be ignored when wind speeds are low and vehicle speeds are high. In the TB-EPDS, the atmospheric wind effect was not applied. Drivetrain Inertial Loss (FI) The engine, transmission, drive shaft, axles and wheels are all in rotation. The rotational speed of each component depends upon the transmission gear ratio, the final drive ratio, and the location of the component in the drive train (i.e. the total gear ratio between each component and the wheels). The rotational moment of inertia of components in the drivetrain constitutes a resistance to change in motion. The torque delivered by each rotating component to the next component in the power chain (engine to clutch/torque converter, clutch/torque converter to transmission, transmission to drive shaft, drive shaft to axle, axle to wheel) is reduced by the amount necessary to increase angular rotation of the spinning mass during vehicle acceleration. Given the torque loss at each component, the reduction in motive force available at the wheels due to inertial losses along the drivetrain can be modeled with the following equation. FI a * I EFF a *[( IW (Gd2 I D ) (Gt2 Gd2 ) * ( I E I t )] r2 r2 (Equation 5) Where: a is the acceleration in the direction of vehicle motion (ft/sec2) IEFF is the effective moment of inertia (ft- lbf -sec2) IW is the rotational moment of inertia of the wheels and axles (ft-lbf -sec2) ID is the rotational moment of inertia of the drive shaft (ft-lbf -sec2) IT is the rotational moment of inertia of the transmission (ft-lbf -sec2) 8 Prepared for the 98th AWMA (2005) Meeting by Yoon, S., Li, H., Jun, J., Guensler, R., and Rodgers, M. IE is the rotational moment of inertia of the engine (ft-lbf -sec2) Gt is the gear ratio at the engine transmission Gd is the gear ratio in the differential r is wheel radius (ft) For the estimation of combined transmissions gear ratio and differential gear ratio, the research team used vehicle speeds and engine revolution per minute (rpm) data from EPA heavy-duty vehicle test results (14). For wheel and engine inertia, typical inertia values suggested by Gillespie (15) were used. For inertia values for transmissions and drive shaft, the research team used inertia values suggested by a rotational part manufacturer (16). With rotational moment of inertia of parts and the combined gear ratios, the effective moment of inertia was estimated. To implement the estimated effective moment of inertia to the TB-EPDS, a curve fit model from the relationship of speed and the effective moment of inertia (IEFF) was introduced. However, this curve fit model should be significantly improved because the effective moment of inertia varies in wide ranges at low vehicle speeds. The wide variation of the effective moment of inertia is mainly associated with mechanical characteristics of power system at a driving condition and by drivers’ driving habits. Engine Power Demand Estimation In the TB-EPDS, negative or zero tractive engine power can be estimated while a vehicle is in deceleration, motoring, or idling mode. Due to the lack of data, however, the activity causing vehicle deceleration can not be clearly identified; that is that vehicle can be decelerated by road grade increase, braking, or natural speed reduction. Because the relationship between engine power demand and bus deceleration rate can not be identified, negative engine power demand should be not currently applied in the TB-EPDS. Therefore, the research team established a criterion that separates tractive (at positive engine power demand) activity and motoring (at negative or zero engine power demand) activity while the bus is running. If estimated tractive engine power demand is less than or equal to zero, the vehicle activity is defined to be motoring, and engine power demand is assumed to be associated only with auxiliary power demand.1 However, if estimated tractive engine power demand is positive, the positive tractive engine power demand is added to the auxiliary power demand (Figure 2). Once power demand is estimated for a cell, activity frequency corresponding to the cell will be multiplied to the power demand in the cell. Then, engine power demand for each cell will be added for the estimation of total engine power demand on a roadway link. 1 The researchers recognize that motoring activity emissions may be significantly different than idle, and that additional research to better quantify motoring emission rates is warranted. 9 Prepared for the 98th AWMA (2005) Meeting by Yoon, S., Li, H., Jun, J., Guensler, R., and Rodgers, M. Figure 2: Transit Bus Engine Power Demand Estimation Flow Chart • Input Parameters to Estimate Tractive Power V W )*(( a) FR FW FD FI ) ] 550 g * Only Applies with Speed-AccelerationRoad Grade Matrices [ ( • No Auxiliary Power IF (Tractive Power > 0) Yes Auxiliary Power Tractive Power + Auxiliary Power Activity Frequency* Activity Frequency* Total Engine Power Demand RESULTS AND DISCUSSION Transit bus engine power estimated with route-based and link-based speed-accelerationroad grade matrices was compared to the engine power estimated with individual secondby-second speed, acceleration, and road grade. For route-based matrices, bus activity data on bus service start and end links were not included because bus activity data on those links were extremely different from activity data on the other links. However, for linkbased matrices, bus activity data on service start and end links were used to create matrices for each start and end link. Total engine power demand estimated with route-based speedacceleration-road grade matrices and with link-based matrices was not significantly different from the total engine power demand estimated with individual speed, acceleration, and road grade throughout the entire bus route (28 miles for a round trip). However, differences in engine power demand predicted for individual links using route-based 10 Prepared for the 98th AWMA (2005) Meeting by Yoon, S., Li, H., Jun, J., Guensler, R., and Rodgers, M. speed-acceleration-road grade matrices and using second-by-second operation data were significant. However, percentage differences in engine power demand predicted for individual links using link-based speed-acceleration-road grade matrices were not significantly different from the predictions using the second-by-second data. Engine Power Demand with Route-Based Matrices and Second-bySecond Speed, Acceleration, and Road Grade Data Route-based speed-acceleration-road grade matrices were created with 3, 5, and 10 mph speed bin interval increments. Total engine power demand across these matrices were +0.31%, -0.36%, and -0.67% relative to total engine power demand predicted using the second-by-second data. Table 1 shows percentage differences of total engine power between route-based matrices and second-by-second data, when matrices are employed with speed bins at 3, 5, and 10mph increments, acceleration bins at 1 and 2mph/s increments, and road grade bins at 1.1% increment. Table 1: Percentage Differences of Total Engine Power with Route-Based Matrices to Individual Second-By-Second Data. Acceleration Bin Increment (mph/s) 1 2 3 -0.67 +5.64 Speed Bin Increment (mph/s) 5 -0.36 +5.97 10 +0.31 +6.70 Percentage differences between route-based matrices and individual data were +5.64, +5.97, and +6.70% with acceleration bins at 2mph/s increment for matrix speed bins with 3, 5, 10mph increments, respectively. These percentage differences were about 20 times greater than with 1mph/s acceleration bin increment. Therefore, 1mph/s acceleration bin interval increment should be the minimum for developing matrices. As expected, as the range of speed bin intervals in matrices becomes the narrower, total engine power demand predicted using matrices was the closer to the total engine power demand predicted from second-by-second data. Because engine power demand is nonlinear with speed or speed*acceleration, engine power demand can vary significantly, depending upon the actual speed and acceleration data points that are aggregated into matrix cells. In this study, the total engine power with route-based matrices having 1mph/s acceleration bins and 3 and 5mph speed bins underestimated the total engine power compared to the use of individual second-by-second data. Although there are marginal engine power differences according to different bin intervals, total engine power demand estimated with speedacceleration-road grade matrices were close to the total engine power demand estimated with individual speed, acceleration, and road grade. By comparison the total engine power demand difference on each link level, engine power predictions using route-based matrices differed significantly from predictions using individual second-by-second data. The differences ranged from -55.9% to +105.1% depending on links (Figure 3). 11 Prepared for the 98th AWMA (2005) Meeting by Yoon, S., Li, H., Jun, J., Guensler, R., and Rodgers, M. Figure 3: Engine Power Demand Difference with Route-Based Matrices with 5mph Speed Bin Increments and with Individual Second-by-Second Data 120 Engine Power Demand Difference (%) 100 80 60 40 20 0 -20 -40 -60 -80 178 172 167 162 157 152 146 141 136 131 126 121 116 111 106 101 96 91 86 81 76 71 66 61 56 51 46 41 36 31 26 21 16 11 6 1 Link ID Differences on links between engine power demand with route-based matrices and individual second-by-second data are because of wide range distributions of motoring/idling fractions among road links. On individual links, motoring/idling fractions ranged from 0.7% to 91.4%. Meanwhile, motoring/idling fractions with route-based matrices were constant with 54.7% and 45.4% for arterials and local roads. Engine Power Demand with Link-Based Matrices and Second-by-Second Speed, Acceleration, and Road Grade Data For each link, link specific speed-acceleration-road grade matrices were created with 3, 5, and 10mph speed increments. Acceleration rates and road grade bin intervals were with 1 mph/s increment and 0.5 degree (1.1%) increment. Total engine power demand with linkbased matrices were +0.25%, -0.39%, and -0.69% different from the total engine power demand with individual data for link-based matrices with 3, 5, and 10mph increment, respectively. Without engine power demand on bus service start and end links, total engine power demand with link-based matrices were the same as the estimated power with route-based matrices. However, percentage differences of power demand on links between 12 Prepared for the 98th AWMA (2005) Meeting by Yoon, S., Li, H., Jun, J., Guensler, R., and Rodgers, M. link-based matrices and individual second-by-second data were narrowly ranged from 5.9% to +6.7% (Figure 4). Figure 4: Engine Power Demand Difference with Link-Based Matrices with 5mph Speed Bin Increment and with Individual Second-by-Second Data 10 Engine Power Demand Difference (%) 8 6 4 2 0 -2 -4 -6 -8 -10 176 171 166 161 156 151 146 141 136 131 126 121 116 111 106 101 96 91 86 81 76 71 66 61 56 51 46 41 36 31 26 21 16 11 6 1 Link ID In comparison of engine power demand differences with route-based matrices, percentage difference of total power demand with link-based matrices varied ten times shorter ranges than with route-based matrices on the link level. That is because link-based matrices reflect almost same motoring/idling fractions to aggregated motoring/idling fractions from individual data on each link. Application of Speed-Acceleration-Road Grade Matrices in Modal Emissions Models Speed-acceleration-road grade matrices generated from transit bus speed and position data can be directly used to estimate transit bus modal activity-based emissions rates in grams per hour because transit bus engine power demand is simply multiplied by transit bus baseline emissions rates (grams/bhp-hr), which varies by engine model year. For the estimation of link level emissions rates, baseline emissions rates by model year will be weighted by aggregated engine power demand at given speed, acceleration, and road grade, multiplied by vehicle miles traveled (VMT), and divided by link length. 13 Prepared for the 98th AWMA (2005) Meeting by Yoon, S., Li, H., Jun, J., Guensler, R., and Rodgers, M. ERm ( BER * Pj ,k ,l * i j k l m VMTm )i SLm (Equation 6) Where: ER is the transit bus emissions rate (g/hr) BER is the baseline transit bus emissions rate (g/bhp-hr) P is the transit bus engine power demand (bhp-hr) VMT is the transit bus miles traveled (miles/hr) SL is the link length (miles) i is the transit bus engine model year j is the median speed in a speed-acceleration-road grade matrix k is the median acceleration in a speed-acceleration-road grade matrix l is the median road grade in a speed-acceleration-road grade matrix m is the roadway link To illustrate the application of Equation 6, one road link was randomly selected from the bus route 55, and nitrogen oxides (NOx) emissions rates were estimated. Baseline emissions rate for the model year 2001 transit bus was 3.9g/bhp-hr. Estimated engine power demand with link-based speed-acceleration-road grade matrices with 5 mph speed bin interval was 10.67bhp-hr. The selected link length and travel distance was 141 meters and 2,862 meters per hour. Estimated transit bus emission rate was 845g/hr of NOx from a vehicle operating on the selected link. With individual speed, acceleration, and road grade, estimated engine power demand on the link was 10.03bhp-hr, and estimated transit bus emissions rate was 794g/hr of NOx. Based on the relationships among engine power demand, baseline emission rates, and vehicle activity data, Georgia Tech is currently developing a more comprehensive GISroad link based, modal activity-based modeling approach for transit bus and heavy-duty vehicles. CONCLUSION This research developed transit bus speed-acceleration-road grade matrices for use in modal activity-based transit bus engine power demand models, which can be directly used to estimate transit bus emissions rates. In the application of transit bus emissions inventory development, both methods with speed-acceleration-road grade matrices and with secondby-second speed, acceleration, and road grade resulted in same transit bus engine power demand. Although both methods resulted in similar power demand predictions, using route-based matrices results in much faster engine power demand calculations than using second-by-second data or link specific speed-acceleration-road grade matrices. However, in application of microscale air quality analyses, route-based matrices did not return reliable transit bus power demand on road link level. There were wide variations of engine 14 Prepared for the 98th AWMA (2005) Meeting by Yoon, S., Li, H., Jun, J., Guensler, R., and Rodgers, M. power demand on links between route-based matrices and individual parameters. Meanwhile, link-based matrices returned transit bus engine power demand estimates that matched well with estimates derived from second-by-second operation data. Therefore, the research team concludes that route-based matrices can be used in the development of transit bus emissions inventories at the regional level, but link-based matrices should be employed when undertaking microscale air quality impact assessments and human exposure analyses. Due to the small size of speed and location data, this paper presents speed-accelerationroad grade matrices only for two aggregated roadway facility types (arterials and local roads) without considering time of day. However, more refined speed-acceleration-road grade matrices, speed and location data should be sub-classified for sub-roadway facility types and for the hour of day. Such matrices can be readily developed for individual transit routes when instrumented data are collected. In the speed and location data collection, the error range at low bus speed can be improved when obtained with more reliable data collection devices such as the differential GPS or the vehicle speed sensor via an engine connection. In addition, speed-acceleration-road grade matrices will likely need to reflect the differences expected to occur in vehicle performance as a function of passenger loading (gross transit bus weight). That is because speed and acceleration patterns will be changed according to the change of transit bus weight on same road grades. Further, bus driver behavior should eventually be investigated and incorporated into the matrices. That is because different bus drivers likely drive the same bus on the same route in a different manner and differences in acceleration patterns will result in different engine power demands. ACKNOWLEDGEMENT Authors express their thanks to Mrs. Sebastian Salontai, William Muckenfuss, James Steward, and Seyed Mirsajedin, of the Metropolitan Atlanta Rapid Transit Authority, who helped to complete this study. Authors also express their thanks to unidentified bus drivers who drove the bus equipped with a Georgia Tech trip data collector. REFERENCES 1. USEPA. EPA’s New Generation Mobile Source Emissions Model: Initial Proposal and Issues; U.S. Environmental Protection Agency, 2001; EPA420-R-01-007. 2. Nam, E. K. Proof of Concept Investigation for the Physical Emission Rate Estimator (PERE) for MOVES; U.S. Environmental Protection Agency, 2003; EPA420-R-03-005. 3. Yoon, S.; Li, H.; Ogle, J.; Guensler, R.; Rodgers, M. A Methodology for Developing Transit Bus Speed-Acceleration Matrices to be used in Load-Based Mobile Source Emissions Models; TRB 84th Annual Meeting: Washington, DC, 2005. 4. Jun, J. Reliability of GPS speed data in use of transportation research; Personal communication; October 2004. 15 Prepared for the 98th AWMA (2005) Meeting by Yoon, S., Li, H., Jun, J., Guensler, R., and Rodgers, M. 5. Li, H. Reliability of GPS position data in use of transportation research; Personal communication; November 2004. 6. Burden, R. L.; Fairs, J. D. Numerical Analysis, Fourth Edition; PWS-KENT Publishing Company, Boston, MA, 1989. 7. Grant, C. D. Representative vehicle operating mode frequencies: measurement and prediction of vehicle specific freeway modal activity; Ph D. Thesis. Georgia Institute of Technology, Aug. 1998. 8. Georgia GIS Clearinghouse; Map Data & Aerial Photography; Georgia Department of Transportation; See http://gis.dot.state.ga.us/ (Accessed November 2004). 9. Gillespie, T. Fundamentals of Vehicle Dynamics; Society of Automotive Engineers, Inc., Warrendale, PA, 1992. 10. SAE. Information Relating to Duty Cycles and Average Power Requirement of Truck and Bus Engine Accessories – SAE J1343; Society of Automotive Engineers, 2004. 11. SAE. Truck Systems Design Handbook - SAE PT-41; Society of Automotive Engineers, 1992. 12. Truck Index. 1997 Diesel Truck Index; Truck Inces, Inc., 1997. 13. Ford Motor Company; See http://www.nosecone.com/table.htm (Accessed November 2004). 14. USEPA. Heavy Duty Diesel Fine Particulate Matter Emissions: Development and Application of On-Road Measurement Capabilities; U.S. Environmental Protection Agency, 2001. 15. Gillespie, T. Typical inertia values for wheel and engine; Personal communication; November 2004. 16. ZELU. Inertia values for rotating transmissions and drive-trains; Industrias ZELU; See http://www.navarrainfo.com/zelu/application.htm (Accessed December 2004). KEY WORKDS: Transit Bus Engine Power Simulation, Modal Emissions Modeling, and Speed-Acceleration-Road Grade Matrices 16