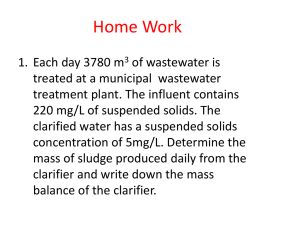

Water & Wastewater Treatment Design Problem Set

advertisement

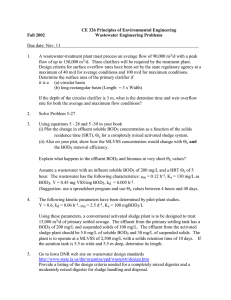

CE 428 Water and Wastewater Treatment Design Problem Set No. 3 Due Date: March 8. 1. Solve Problem 1, page 865 (use Wastewater A and equation 8-1) 2. Solve Problem 3, page 866 (Use wastewater A) 3. A completely mixed activated sludge plant is to treat 10,000 m3/day of industrial wastewater. The wastewater has a BOD5 of 1200 mg/L that must be treated to 200 mg/L (assume all soluble) prior to discharge to a municipal sewer. Pilot-scale analysis indicates that a solids retention time of 5 days and maintaining a MLVSS concentration of 5000 mg/L produces the desired results. The value for Y is determined to be 0.7 kg/kg and the value of kd was 0.03 day-1. Determine (a) volume of reactor (b) mass of solids and wet volume of sludge wasted each day (c) sludge recirculation ratio 4. Solve Problem 8-19, page 871. Please provide a summary table of your answers. 5. Solve Problem 8-36, page 878 (see below for question) Ignore the question but use the data in the Table (note that the distance given in the Table is the distance from the top of the settling column to the sludge interface). With the data in the Table, size the area of a secondary clarifier using the solids flux method. The influent flow rate varies from 1,200 to 2,000 m3/d and the solids concentration is 4000 mg/L. The ultimate compacted sludge is expected to vary from 10,000 to 15,000 mg/L. The solids exiting the clarified overflow can be assumed to be negligible. 6. Solve Problem 9-5 (Wastewater A) and only for questions 1, 2, and 3.