controling nuisance gas emissions from wwtps

advertisement

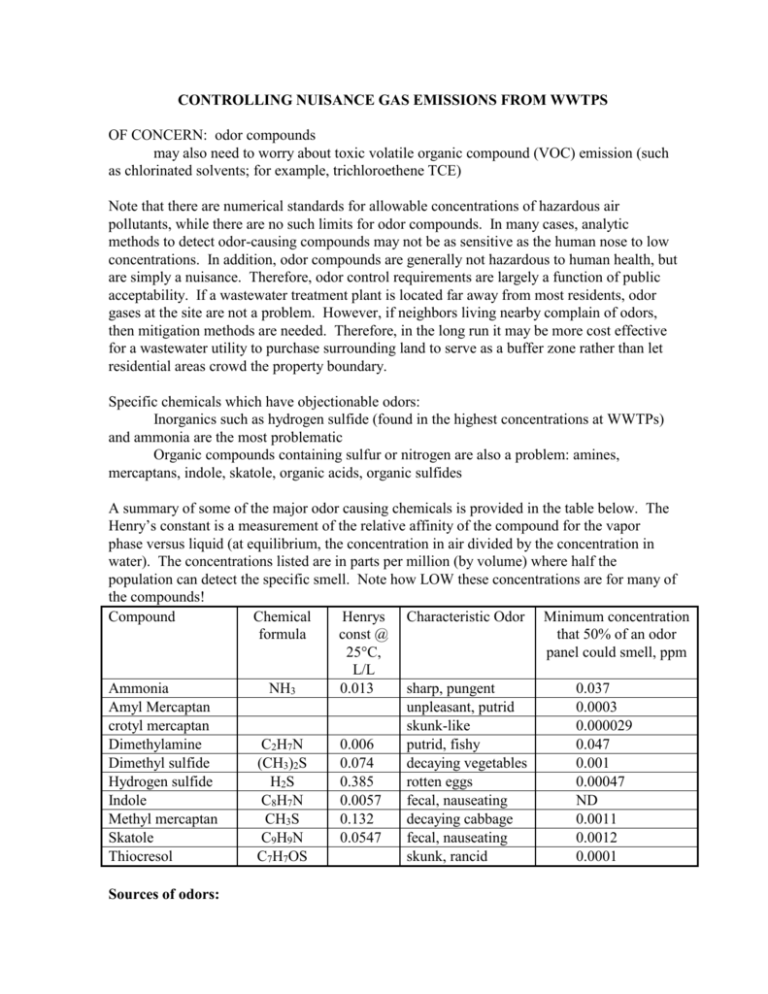

CONTROLLING NUISANCE GAS EMISSIONS FROM WWTPS OF CONCERN: odor compounds may also need to worry about toxic volatile organic compound (VOC) emission (such as chlorinated solvents; for example, trichloroethene TCE) Note that there are numerical standards for allowable concentrations of hazardous air pollutants, while there are no such limits for odor compounds. In many cases, analytic methods to detect odor-causing compounds may not be as sensitive as the human nose to low concentrations. In addition, odor compounds are generally not hazardous to human health, but are simply a nuisance. Therefore, odor control requirements are largely a function of public acceptability. If a wastewater treatment plant is located far away from most residents, odor gases at the site are not a problem. However, if neighbors living nearby complain of odors, then mitigation methods are needed. Therefore, in the long run it may be more cost effective for a wastewater utility to purchase surrounding land to serve as a buffer zone rather than let residential areas crowd the property boundary. Specific chemicals which have objectionable odors: Inorganics such as hydrogen sulfide (found in the highest concentrations at WWTPs) and ammonia are the most problematic Organic compounds containing sulfur or nitrogen are also a problem: amines, mercaptans, indole, skatole, organic acids, organic sulfides A summary of some of the major odor causing chemicals is provided in the table below. The Henry’s constant is a measurement of the relative affinity of the compound for the vapor phase versus liquid (at equilibrium, the concentration in air divided by the concentration in water). The concentrations listed are in parts per million (by volume) where half the population can detect the specific smell. Note how LOW these concentrations are for many of the compounds! Compound Chemical Henrys Characteristic Odor Minimum concentration formula const @ that 50% of an odor 25°C, panel could smell, ppm L/L Ammonia NH3 0.013 sharp, pungent 0.037 Amyl Mercaptan unpleasant, putrid 0.0003 crotyl mercaptan skunk-like 0.000029 Dimethylamine C2H7N 0.006 putrid, fishy 0.047 Dimethyl sulfide (CH3)2S 0.074 decaying vegetables 0.001 Hydrogen sulfide H2S 0.385 rotten eggs 0.00047 Indole C8H7N 0.0057 fecal, nauseating ND Methyl mercaptan CH3S 0.132 decaying cabbage 0.0011 Skatole C9H9N 0.0547 fecal, nauseating 0.0012 Thiocresol C7H7OS skunk, rancid 0.0001 Sources of odors: Raw wastewater that goes “anaerobic” in the sewer lines (consumes all available oxygen) contains anaerobic bacteria that will transform organic sulfur compounds into hydrogen sulfide (H2S). This H2S will tend to be dissolved in the water until the sewage liquid is exposed to turbulence in the inlet junction box or lift pumps and then the H2S will volatilize into the air. Typical sewer off-gas contains 0.1-15 ppm H2S, and 0.01-0.05 ppm organic odor compounds. Anaerobic biological treatment processes may also result in the formation of H2S Scum floating on the surface of primary settling tanks Biosolids drying or dissolved air flotation thickening Aerobic thermophilic sludge digestion, largely ammonia Options: 1. place covers on unit processes such as primary & secondary clarifiers, trickling filters,... these can be structural fabric, aluminum, etc. Cover costs generally range from $12-$80 per ft2 surface area depending on type fixed roof cover for primary clarifiers $12/ft2 in Orange County, CA fixed cover costs generally 12-26/ft2 rigid floating covers $42-$56/ft2 flexible floating cover $3-$7/ft2 air supported structure $54-65/m3 to install; operating costs about 250000 kWH/yr POTW process Aer grit chamber Mech grit chamber Primary Clarifier Activated sludge diff air Activated sludge mech mix Activated sludge pure oxygen trickling filters secondary clarifiers tertiary filters Cl contact chamber aerobic pond removal efficiency operational problems fixed cover Y Y Y Y rigid floating N Y Y N flexible floating N N N N Air supp structure Y POSS Y Y Floating spheres N N N N Y N N Y N Y N N Y NN Y Y Y Y Y POSS N POSS N N N N N POSS N Y Y Y Y Y N N POSS POSS N FIXED COVER 80-95% corrosion of concrete walls, RIGID FLOATING 85-95% difficulty of maintenance, AIR SUPP STR 41-95% corrosion of equip inside cover, inc liq experience at POTWs difficulty w/ maintenance; degradation fr weathering & offgas used at several POTWs complexity not complex cross media impacts cost degradation of seam & cover due to VOCs in WW proc concrete walls; degradation of cover fr ww off-gas used for digester tank covers; used in other ind. for yrs on O/W separators relatively simple used in industry, but not yet at POTWs req more knowledge than other covers due to inflation sys possibility of change possibility of change negligible in sludge in sludge composition composition $13-26 / ft2 $42-100 / sq ft $54-$65 /m3; high energy costs 2. “deodorizing misters” By misting the surface of open tanks, the volatilized odor compounds may dissolve in the mist of air and return to the liquid. The misters may also contain “odor masking” compounds. Many companies have worked to develop chemical mixtures that are specifically designed to neutralize and/or mask odors from wastewater treatment plants. 3. pre-oxidation of odor compounds One way to minimize odors through the wastewater plant is to add chemicals that will react with the odor causing compounds. For example, chlorine can be added at the head of the plant to pre-oxidize -> but this may result in THMs & other volatile organic chlorinated compounds that are a health hazard risk volatilizing out later in the plant (such as chloroform). Alternatively, the addition of FeCl3 (a common coagulant that may be present in sludge from drinking water treatment plants) may also serve to reduce odor emissions through the plant. Treatment of odor gases: 1. dry activated carbon adsorption non-impregnated carbon caustic-impregnated carbon (~5% by weight KOH, NaOH, Na2CO3) non-impregnated carbon with ammonia addition - general bed depths 1-6 ft, 250 cfm air/ft2 convey contaminated gases to the bed: due to corrosive nature use plastic or fiberglass pipes regenerate carbon on-site or send for off-site thermal regeneration humidity in gases reduces sorption capacity cost estimates (73 GAC suppliers in US, about 6 sell complete systems) 10,000 scfm flow and 100 ppmv inlet conc, capital cost $475K, O&M $250K/yr 250-cfm flow capital $20K and O&M $148K removal efficiency operational problems experience at POTWs complexity cross media impacts carbon adsorption can be high for low concs if low velocity flow humidity >80% results in lost sorption capacity; for odor control; industry for 50yrs low, unless monitor breakthru & regenerate on-site high disposal or regeneration cost 2. wet scrubbers with oxidants (hydrogen peroxide, chlorine, ozone, potassium permanganate) may use spray chambers (usu. 50-75’ tall, 200 cfm air/ft2) or packed towers (17’ packing, 30’ total height, ~300 cfm air/ft2) high chemical cost, difficult maintenance & frequent operation attention needed, safety hazards of chemicals cost about $0.70 / 10,000 cfm 3. thermal flares - low-cost, use for gases containing combustible components such as methane, hydrogen, CO; need enough heating value in the gas for self-sustaining burn otherwise need to add supplemental fuel (as would be the case in most WWTP off-gases) catalytic oxidation - waste gas contacts catalyst bed to allow rapid reactions at 700-900°F. catalyst usually noble metal such as platinum or oxides of Cu, Cr, Mn, Ni, and Co. S compounds deactivate certain types of catalyst materials; life of catalyst 2-5 yrs; not common in WWTPs; capital cost for 250 cfm system of $55K and O&M of $20K/yr thermal incinerators (aka thermal oxidizers) - use supplemental fuel (usually natural gas) to burn contaminated gas, temps 800-1500°F, use some form of heat recovery, large space required (300 x 300 ft of land), need scrubber to clean gas of NOx, SOx, and acid gases 4. biological treatment methods: biofilters, biotrickling filters, activated sludge tanks Biofilters: packed bed of media on which the biomass grows humidify inlet air or sprinkle the top of the bed to maintain moisture packing media is soil, peat, compost, wood chips (provide nutrients); generally replace media every 6 mo to 3 yrs need to maintain pH, since biodegradation of H2S & ammonia produces acidic conditions optimum temperature 30-37°C, range 10-42°C; biofilters generate heat from microbial activity which can allow odor control even with below freezing air temperatures commonly 3-5 ft deep, 3-10 cfm air/ft2, 60 sec gas residence time, 40-80% porosity low energy costs compared to other methods; only enough power to overcome 2-3” head loss cost: 10,000 cfm H2S 20 ppm in & <1 ppm out; $97.3K capital, $7.9K/yr O&M (1990) cost: $0.10 / 10,000 cfm ; capital for 250-cfm system $34K, $7200 /yr O&M cost: capital $17-$69 / cfm for a 25K-cfm system, $10-$40 / cfm for a 75K-cfm system Biotrickling filters: plastic media support, upflow air, recirculate some liquid with nutrients 1.14 cfm air/ft2, 24’ deep Activated sludge treatment use the odorous air from the headworks building as the inlet air fed into activated sludge tanks (such as in the Los Angeles Hyperion treatment plant) used for over 30-yrs at WWTPs; used at over 25 plants in U.S. used in Japan where there is an “Offensive Odor Control Law” should use non-ferrous piping and diffusers (probably coarse bubble) to prevent corrosion & fouling perhaps should use stainless steel dry filter fittings & flowmeters; have observed corrosion problems with aluminum & steel guide vanes on the blower no indication that odor air into activated sludge tanks increased problems with filamentous bacteria general aeration rate of 0.25 to 0.5 m2/1000 m3/d; aeration rate 3.5K cfm for a 5-MGD conventional plant; could treat air from the influent channels, aerated grit chamber, primary effluent launders, gravity thickener, bet presses, and sludge holding tanks no increase in odor over the activated sludge tanks when using odorous gases longest experience at the Hyperion WWTP in Los Angeles, which installed odor treatment from headworks, primary clarifiers, DAF thickeners, and effluent pump station in their activated sludge basins in 1959. Since then, they have cleaned the blower twice, reported no corrosion of fine bubble diffusers, and estimate odor removal at 96-99% lab studies found removal of odor compounds to below detection limits of 0.1 ppm in an activated sludge reactor of 2 to 4.2 ft depth; nitrification occurred in the reactor if need activated sludge tanks for ww tmt, no additional capital costs other than selection of proper materials to resist potential corrosion References: Ando, S. 1980. Odor Control of Wastewater Treatment Plants. Journal WPCF. 52(5): 90613. Bowker & Associates. 1996. Biological Odor Control by Diffusion into Activated Sludge Basins. NEWEA Journal. 30(2): 137-146. Environmental Technology. 1988. 8(5): 18-19. Morris & Lecky. Controlling Wastewater Treatment Plant Odors in a Resort Community. Environmental Protection. Feb. 1998. Romain, M. 1996. “Biotreatment of Odor-Containing Gases from Municipal Wastewater Treatment Plants.” Masters Thesis, University of Washington. Bishop, Witherspoon, Card, Chang, Corsi. 1990. VOC Vapor Phase Control Technology. WPCF Research Foundation. Torres, Devinny, et al. Biofiltration: Controlling Air Emissions through Innovative Technology. 1997. WERF. vanLith, C., G. Leson, and R. Michelsen. 1997. Evaluating Design Options for Biofilters. J. Air&Waste Mgmt. 47: 37-48. Williams, T. & F. Miller. 1992. Odor Control Using Biofilters. Biocycle. 33 (Oct/Nov):72-7, 75-9.