Odor Control Solutions

advertisement

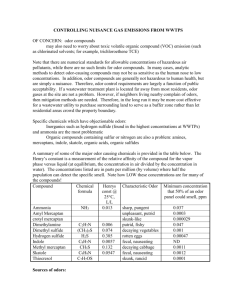

Providing solutions not just products Local representative since 1996 www.GoTDM.com 800.300.2844 Turnkey System integrator and distributor – proving regional field service and installation New company – cooperative venture including TDM and Gasho Associates More capabilities including field service of equipment Developing new technology for dry media System Integrator Contacts TDM:George Federico Technical Assistance – proposals, etc Gasho Associates – Shaun Kelley local sales Rep – Offering multiple technologies Biofilters Carbon/media system Chemical scrubbers Thermal oxidizers Odor prevention Offering the best technologies OdorTool Biofilters Theia Air Carbon & Dry media Altech Scrubbers Colt Technolgies - Oxidizers Venturi Aerators Weatherford H2S Scavenger www.GoTDM.com We provide solutions we work with you to find the best solution for you and your client – we do not force fit what we sell to the project Knowledge and experience We know the technologies and are experts in treating air and odor Scope of supply to fit the project every project has different requirements. We can provide turnkey systems and even install them or just components - your call www.GoTDM.com The TDM/Theia Air difference We work with you when you are designing your system, installing your system and for years afterwards – all systems and equipment can have problems – we will be there for you if ours does We will be there for our customers – even when it is not our equipment www.GoTDM.com The TDM/Theia Air difference We provide a total approach to odor control. This means everything from collection to dispersion www.GoTDM.com Odor is a sensory reaction to one or more aromatic gases. Like noise, it is a perceived offense. Like Noise, this somewhat nebulous term CAN be scientifically defined We define one OU ( odor unit) as the point at which the “average person” begins to detect an odor Malodor Odor Description Hydrogen Sulfide Mercaptans Rotten eggs Skunk, rotten cabbage, putrid garlic Rotten vegetables Decayed vegetables Fecal, nauseating Putrid, fishy Pungent, irritating Carbon Disulphide Dimethyl sulphide Indole, Skatole Amine Ammonia Odor Threshold 3 ppb 20 ppt to 300 ppt 200 to 800 ppb 1 ppb 100 ppt 400 ppt to 100 ppb 17 to 50 ppm Removing some of the compounds will reduce the odor but may not eliminate the problem We must reduce all of the odorous compounds to be successful Simply put, we are trying to prevent odorous compounds from reaching sensory perceptors ( people) Before we design the treatment equipment, we should define what is required to meet this goal Dispersion Modeling In general, contaminated air passes through a fixed bed of media Media has a thin film of water on the outside Contaminant gases are solubilized into this film of water where they can be digested by the microbes Just because something looks good on paper does not mean it will work in the field Surface Velocity –must be slow enough to allow capture – this affects the diameter of our unit but is not usually in play, EBCT – residence time, contact time, etc –a relatively useless measure, on its own, used by engineers to try to normalize a bid – useful EBCT or pore volume is what actually matters – not unlike carbon. To some extent, the more pore volume, the better the performance but there are diminishing returns Media Makes a Difference ! Synthetic media is now widely used – media does not break down The media will last but the performance is still not there Random Packed Media: Void volume only 35% (Less Effective EBRT) poor water distribution poor air flow No means for control of biomass Higher Pressure Drop, increases over time Un-Predictable performance Media is typically treated with chemicals, food, etc • • • • • • Void or pore volume is all that really matters – and they fall short Effective bed volume Dry = no bacteria and no solubilization Water and biomass buildup block the air sending it elsewhere Water build up and dry spots render another portion as useless So what is the actual effective EBCT ???? Dual Zone Bed; Zone A provides an optimal area for a robust colony of bacteria to reside while Zone B is the “transfer zone” . Void Volume >95% (Effectively increases EBRT) Complete treatment, due to uniform distribution of air Low pressure drop, will not increase over time Maintains its structure over life ensuring predictable performance Bacteria Growth Air flow Vessel Size Water Layer Water Layer Air flow Vessel Size 95 % Void Volume 100% media utilization no Water Buildup Water Layer Air flow Vessel Size No dry spots Most Systems are overly complicated • larger media beds – big footprint, very heavy •Typically very expensive •Humidification systems – complicated – require a lot of maintenance •Multiple spray nozzles One spray nozzle = even distribution of water No recirculation of water No humidification system Control the water –► control the air, control the bugs Most biofilters fail due to poor control of the water – uneven water = uneven air = poor treatment = poor biomass By controlling the flow of water through the system we control the air flow keeping it evenly distributed What does the air flow pattern look like here ? Bacteria Growth Water Layer Air flow › Biomass control. Getting a strong healthy bacteria colony to grow is important but is only part of the battle Keeping this biomass from fouling or otherwise interfering with the equipment is just as critical Multiple contaminants require multiple bacterial colonies This requires multiple strata to develop which strongly favors a taller media bed We do not recirculate the water which allows this stratification to take hold Lighter VOC’s Mercaptans Aldehydes, Ketones TRS H2S Odortool biofilters are compact, require little or no maintenance and use little water and no chemicals These systems offer high removal efficiencies and very low operating costs Permanent media means no replacement concerns Taking on your toughest applications without all the mess and expense of wet scrubbers. New media that can take on the highest levels of H2S & mercaptans without a big footprint and without changing the media out frequently Thermal Oxidizers are effective on sludge applications RTO’s ( Regenerative Thermal Oxidizers) are the best approach – lowest maintenance and lowest operating costs They are slightly more expensive than RCO’s ( Recuperative thermal oxidizers) – usually 5-15% we offer skid mounted and field erected RTO’s ( Regenerative Thermal Oxidizers to treat any size air stream – we also offer RCO’s Biosolids, Sludge, drying, etc is our specialty We offer upgrades and retrofits to existing units to reduce your operating costs •27 years of experience •Full field capabilities •Safe, reliable design For sludge drying and other low VOC applications, RTO’s are the best choice. •RTO’s use a lot less fuel •RTO’s require a lot less maintenance •RCO’s typically require a rebuild after 5-7 years due to the heat exchangers rusting out Structured media Our design allows for removal of heat recovery media from the chambers quickly and easily Media can be cleaned and put back in all in one day This will be required once every 2-3 years Colt is the recognized leader in Thermal Oxidizers but we do not stop there We offer the best field and technical support of any company We spend a lot of time replacing or fixing our competitors units Other Products Another method is to permanently eliminate the H2S and Mercaptans using a little chemistry Sulfa Clear from Weatherford Patented technology from the oil & gas industry that safely and effectively eliminates H2S Proven over 20 years of history Polymeric Amine Condensate that converts sulfides to a Polyamine Sulfide Introduced at a single or multiple injection points Non-Hazardous Non-Flammable Freeze point in excess of -20F No special storage considerations No mixing required Permanently eliminates H2S & mercaptans Is specific to these compounds – can be added in one place Reacts to form a corrosion inhibitor No solids build up Environmentally friendly Ease of handling There are several important steps to designing the best odor control system for your your project We are here to help There is no one right technology for all applications Often a single technology is not the best approach Especially for a complex mixture of odors as we see in sludge handling For these applications the two main approaches are Biofilter/carbon Oxidizer Start with Biofiltration Biological Treatment is most effective on compounds which are soluble or partially water soluble Compound H2S Aldehydes Ketones Removal efficiency 99% plus 90-99% 90- 99% Mercaptans: 75-85% DMS/DMDS : 65-75% VOC’s 55-85% ( depending on weight, etc) It is the capture and destruction of compounds using a complex combination of bacterial colonies which consume the various contaminants We must first capture the contaminants Then create the ideal environment for these multiple bacterial colonies to do their work without impeding the airflow Surface Velocity –must be slow enough to allow capture – this affects the diameter of our unit but is not usually in play, EBCT – residence time, contact time, etc –a relatively useless measure, on its own, used by engineers to try to normalize a bid – useful EBCT or pore volume is what actually matters – not unlike carbon. To some extent, the more pore volume, the better the performance but there are diminishing returns Based on a flowrate of 600 CFM, we can use our second smallest series, 1500 which indicates a 5 foot diameter media bed Because of the variety of compounds present, we want as many layers of media as possible. 3 layers is the maximum number for these smaller systems and we have a height and size limitation. We check the initial design to verify the design point. Based on the number of CFU’s required and number of colonies, this is sufficient media volume and height to achieve 90-95% odor removal through this stage Next – look at dry media As with Biofilters, design is everything – stuffing a bunch of carbon into a drum is not going to cut it We utilize 2-5 different medias depending on what we are expecting to see Combined Efficiency of dry media unit Compound H2S Aldehydes Ketones Removal efficiency 99% plus 90-99% 90- 99% Mercaptans: 99% DMS/DMDS : 99% VOC’s 95-99% ( depending on weight, etc) TA- OC – • surface modified media – removes H2S and other reduced sulfur compounds as well as some nitrogen molecules •It is also a virgin carbon that will remove some VOC’s – heavier ones TA-OM – •Chemically impregnated media – oxidizes the more difficult compounds and captures them – •Very effective on mercaptans as well as DMS, etc TA-VCC •Virgin carbon – microporous – removes the most aromatic compound 0.203 0.2 2.135 0.3765 0.642 1.281 2.1 After Secondary media After Primary Media 10.15 0.8 8.54 2.51 4.28 8.54 0.88 7 After Bio INLET(PPMV) COMPOUND Hydrogen Sulfide Carbonyl Sulfide Methyl Mercaptan Acetaldehyde Isobutyraldehyde isovaleraldehyde p-cymeme 2-methylbutanal 0.00203 0.01 0.10675 0.018825 0.0321 0.06405 0.105 Because dry media is consumable, we must check the usage of the media to verify that we will have sufficient bed life to achieve the required odor removal for the prescribed period of time before the media requires replacment. Final step ( is actually based on the first one) Dispersion enhancement – basically we are using our surroundings as well as our discharge to mix what little odor remains with as many air molecules as possible so that by the time the off-gas reaches people, we are below one OU