experiment 2

advertisement

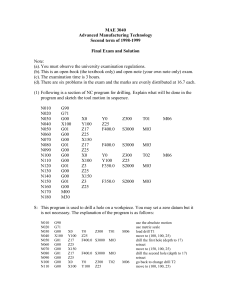

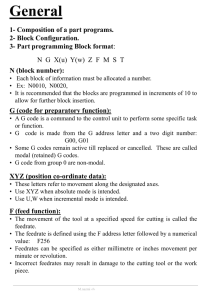

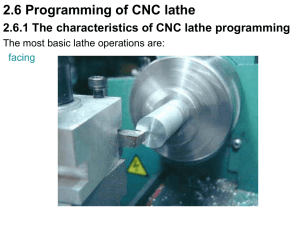

ME 445 INTEGRATED MANUFACTURING TECHNOLOGIES EXPERIMENT 2 “PROCESS PLANNING IN TURNING MACHINE” OBJECTIVE In this experiment, you are required to design and manufacture a sample chess part in CNC Turning Machine. For this purpose, you will design a chess part with the given restrictions, make its technical drawing and write G-Code listing for Turning Machine. The aim of the experiment is not only to become familiar with the basic instructions of the ISO G-Code programming techniques but also give an idea about the “Concurrent Engineering”, namely the “design for manufacture”. The student should take care about the restrictions about the machine, tooling and capacity as well as the manufacturability and aesthetic considerations of the designed part. Figure: Overview of the METUCIM System RAW MATERIAL The raw material is a bar made of aluminum with a diameter of 30 and it is continuously fed into CNC turning machine. The chess piece you will design must be 50 mm long, so you can consider your raw material as a 50 mm long, 30mm diameter aluminum billet. Figure 1. Raw material part drawing 1 TOOL SPECIFICATIONS Turning Machine Tool ID T1 Description Tool Drawing Right Hand Side Cutting Tool. L=17 mm, α=55° Preferred for rough cutting operations. Maximum depth of cut 3 mm in diameter. T6 6 Drill. a=6 mm, b=37 mm. Prior to this, Center Drill (T8) must be applied. T8 Center Drill. a=3 mm, b=5 mm, c=5 mm, d=8 mm Must be applied prior to any drilling operation. T10 Slotting and Parting Tool. a=3mm, b=20mm. Capable to cut in radial direction only. Reference point is the left corner as indicated in the figure. 2 G CODE LISTINGS OF SIEMENS SINUMERIK 802D TURNING MACHINE G0 Rapid traverse G1 Linear interpolation G2 Circular interpolation in clockwise direction G3 Circular interpolation in counterclockwise direction G4 Dwell time G10 Load zero offset/tool offset G11 End loading of zero offset/tool offset G18 Select machining plane Z-X G20 Input system in inches G21 Metric input system G28 Reference point approach G30 Reference point 2nd, 3rd, 4th ref. point approach G31 Measure using switching pushbutton G32 Thread cutting with constant pitch G40 Tool radius offset OFF G41 Tool radius offset to the left of the contour ON G42 Tool radius offset to the right of the contour ON G54 Workpiece coordinate system G90 Absolute Dimensioning G91 Incremental Dimensioning G94 Feed per minute [mm/min] G95 Feed per revolution [mm/rev] G96 Constant cutting speed ON G97 Constant cutting speed OFF G98 Feedrate in mm/min, inch/min G99 Feedrate in mm/rev, inch/rev G290 Deselect ISO Dialect programming G291 Select ISO Dialect programming M CODE LISTINGS OF SIEMENS SINUMERIK 802D TURNING MACHINE M0 Programmed stop M1 Optional stop M2 Program end (main program) M3 Clockwise rotating spindle M4 Counterclockwise rotating spindle M5 Spindle stop M6 Tool change M30 Program end as for M2 M17 Subroutine end M98 Subroutine call M99 Subroutine end M19 Spindle positioning M70 Reserved for Siemens 3 CIRCULAR INTERPOLATION The following commands will move a tool along a circular arc: In order to cut along the circular path with RHS tool, first tool must be placed at X3 Z5. Circular arc can be created by G02 or G03 giving the destination point and the radius: G01 X3 Z5 F0.2 ;go to starting point X3 Z5 G02 X5 Z3 R2.5 F0.1 ;cut clockwise until X5 Z3 with radius 2.5 SAMPLE PART PROCESS PLAN PART DRAWING 4 PART G-CODES ;NOTE THAT COMMENTS BEGIN WITH “;” CHARACTER ;THEY HAVE NO EFFECT ON THE PROGRAM ;IN YOUR PROGRAM USE COMMENTS FOR READIBILITY ; ---------- PREPARATORY COMMANDS ---------G291 ;ISO dialect G91 G28 X0 Z0 ;Go to reference point G90 ;Absolute dimensioning G21 ;Input in mm G95 ;Feed in mm/rev G18 ;Select Z-X Plane for turning G40 ;Tool radius offset is off G54 ;Coordinate system is on the work piece S1500 ;Spindle speed is 1500 rpm ; ---------- FACING OPERATION ---------T1 ;Select right hand side cutting tool M03 ; Rotate spindle in CW direction G00 X34 Z4 ;NOTE THAT X IS DEFINED AS POSITIVE DIAMETER G01 Z0 F0.2 G01 X-1 F0.1 G00 X34 Z4 ;ROUGH CUTTING (ONLY TWO PASSES ARE ENOUGH) G00 X27 G01 Z-28 F0.1 G01 X34 F0.2 G00 Z4 G00 X24 G01 Z-9.5 F0.1 G01 X34 F0.2 G00 X34 Z4 ;FINE CONTOUR CUTTING EXCEPT POCKET WITH 3 RADIUS G00 X23 G01 Z-10 F0.1 G01 X26 Z-12 ;CHAMFER IS CUT G01 Z-30 ;NO POCKET YET G01 X30 Z-42 ;INCLINED SURFACE G01 X34 F0.2 G00 Z2 G91 G28 X0 Z0 ;Go to reference point G90 ;Absolute dimensioning 5 ;NOW CUT THE POCKET WITH PARTING TOOL ;AT EACH CUT TOOL IS ADVANCED FOR 2.5 mm AT MOST M05 ;Stop the spindle T10 ;Select grooving tool M03 ;Start the spindle G00 X27 Z-21 G01 X20 F0.1 ;1ST CUT G01 X27 F0.2 G00 Z-23.5 G01 X20 F0.1 ;2ND CUT G01 X27 F0.2 G00 Z-26 G01 X20 F0.1 ;3RD CUT G01 X27 F0.2 G00 Z-27 G01 X20 F0.1 ;4TH CUT G01 X27 F0.2 G00 X32 Z2 G91 G28 X0 Z0 ;Go to reference point G90 ;Absolute dimensioning ;NOW CUT THE POCKET RADIUS WITH RHS TOOL AGAIN M05 ;Stop the spindle T1 ;Select RHS tool M03 ;Start the spindle G00 X27 Z-27 G01 X20 F0.2 G03 X26 Z-30 R3 F0.1 ;CCW CIRC. INTERPOLATION G01 X27 F0.2 G00 X32 Z2 G91 G28 X0 Z0 ;Go to reference point G90 ;Absolute dimensioning ;NOW PERFORM THE DRILLING M05 ;Stop the spindle T8 ;Select center drilling tool M03 ;Start the spindle G00 X0 Z2 G01 Z-7 F0.1 G01 Z2 F0.2 G91 G28 X0 Z0 ;Go to reference point G90 ;Absolute dimensioning M05 ;Stop the spindle 6 T6 ;Select 6 drilling tool M03 ;Start the spindle G00 X0 Z2 G01 Z-10 G01 Z2 F0.2 G91 G28 X0 Z0 ;Go to reference point G90 ;Absolute dimensioning ;CUTOFF THE PIECE WITH THE PARTING TOOL M05 ;Stop the spindle T10 ;Select grooving tool M03 ;Start the spindle G00 X34 Z53 G01 X-1 F0.1 G01 X34 F0.2 G91 G28 X0 Z0 ;Go to reference point G90 ;Absolute dimensioning ;OPERATION IS COMPLETE M05 ;SPINDLE STOP M30 ;PROGRAM STOP 7 INSTRUCTIONS FOR THE EXPERIMENT Before the Experiment 1. All group members must haven taken part in Part Design Process, their individual contribution will be observed and graded by the lab assistant. 2. At the lab hour you are required to: The code must be written in NotePad (not Word or anything else) You should press Enter key after the M30 line in your code (The CNC machines need an empty line at the end of the code) It would be better if you use comments to seperate some major parts of your code. When you finished coding, save the file as with the name as (without using Turkish characters) “GroupNo_ME445exp2.txt” and then, change the file type to .mpf (If you can not see the file name extensions, open any folder, go to Tools (for Windows Vista and 7, you may need to press Alt+F (English) or Alt+D (Turkish) to see the menu bar), in the Tools, click Folder Options, go to View tab, uncheck the “Hide file extensions....” option.) Bring 2 copies of the part drawing and 2 copies of printouts of your code. Printouts of the part drawing and code are necessary for the debugging and grading of your code. Bring your code in a USB Flash Drive. During the Experiment The 30 aluminum raw material will be supplied at the laboratory. Your programs will be loaded to the machine controller. Your G-Code files will be controlled and debugged by the assistant for safety considerations. The part will be manufactured in Turning Machine. The part will be retained by the assistant for grading. Grading Your individual contributions will be assessed and graded. You are required to submit your G-Code Listings and Part Drawing one week after the lab date until 17:30. Your submission will be graded. Take care of that your design is simply manufacturable. Irrelevant design can not be debugged and processed. Also be sure that, you have not exceeded machine limits. 8