Virtual CNC machining - Hong Kong University of Science and

advertisement

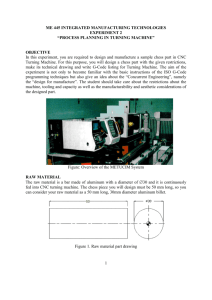

Virtual CNC machining & G-code Dept. of Mechanical Engineering The Hong Kong University of science and Technology Outline • Introduction of virtual CNC machining system User interface Interactive operation Controller operation Example • Introduction of G-code Terminology Address character Suggestions Examples Part1: Virtual CNC machining NC codes Coordinates System parameters Control panel Machine tool Controller Virtual CNC machining: Interactive operation Safety door can be open View option Set transparency • Hold the left button: move left and right/ zoom in and zoom out • Hold the middle button: move up and down • Hold the right button: rotate Virtual CNC machining: Interactive operation Coolant pipe • Press “L”, switch on/off the “light” • Press ”S”, show/hide the “coolant pipe” Virtual CNC machining: Controller operation Single block switch Home return light Over travel alarm Default operation modes Emergency stop knob Hand wheel Virtual CNC machining: Controller operation 1. MEM: To cycle start the NC codes simulation 2. MDI: Manual Data Input that could be used to enter some NC blocks 3. Zero RTN: To return to machine HOME positions of X, Y, and Z axes 4. JOG: To move X, Y, Z axes individually 5. Handle: To operate the virtual machine tool by the wheel of mouse 6. Rapid: To rapidly move X, Y, Z axes individually 7. Step: To move X, Y, Z axes stepwise Virtual CNC machining: Controller operation Zero return: 1. Click the “zero RTN” operation mode Why Z-axis should be zero returned first?? 2. Choose the “Z” axis in XYZ option 3. Click “zero return” button to initiate the Z-axis zero return 4. Next, zero return X-axis and Y-axis respectively Virtual CNC machining: Controller operation Jog: move x, y, z axes individually 1. Click the “JOG” operation mode 2. Choose the axis 3. Select the jog speed 4. Select the direction and jog Virtual CNC machining: Controller operation Handle : move x, y, z axes by rolling the wheel 1. Click the “Handle” operation mode 2. Choose the axis 3. Select the multiple 4. Roll the wheel of mouse to “handle” the axis Virtual CNC machining: Controller operation Rapid: To rapidly move X, Y, Z axes individually 1. Click the “Rapid” operation mode 3. Select the movement speed 2. Choose the axis 4. Select the direction and move rapidly Virtual CNC machining: Controller operation Step: To move X, Y, Z axes stepwise 1. Click the “Step” operation mode 2. Select the direction and move stepwise Virtual CNC machining: Controller operation MDI: Input NC blocks and execute in MDI mode 2. Input your NC blocks here 1. Click the “MDI” operation mode 3. Cycle start to execute NC blocks 0. Zero return Z-axis first! Virtual CNC machining: Controller operation MEM: Automatic execution mode 2. Select the NC file 3. The NC code will be read and shown in the screen 1. Click the “MDI” operation mode 4. Cycle start to execute NC blocks Virtual CNC machining: Controller operation Emergency stop • Click this button for emergency stop. • The execution will be stopped. • Release the button to enable the controller again. Virtual CNC machining: Controller operation Spindle speed control: The rotation speed of spindle can be controlled by these six buttons, and also by S code (will be discussed in the following slides) • • • • • • CW: Clockwise STOP: Stop rotating CCW: Counter-Clockwise Inc: Increase Speed Nor: Normal Speed Dec: Decrease Speed Virtual CNC machining: Tool exchange There are 10 built-in milling cutters in the tool magazine. The related cutter dimensions and descriptions can be shown by selecting the “Tools” menu under the “Config” menu. Virtual CNC machining: Tool exchange 3. Input tool exchange command, for example “M6 T10” 2. Choose MDI mode 4. Click Cycle Start to execute tool exchange 1. Zero return Z-axis first for too exchange Virtual CNC machining: Automatic edge-finding 1. Zero return Z-axis. 2. Load the workpiece 1 (if not). 3. Change to the cutter T3. 4. Choose “Auto edge finding” function. 5. The “Auto edge finding” window will be prompted. 6. Use JOG and Handle mode to Move the T3 cutter to the location “X015.792”, “Y098.630, and Z004.171, near the edge of workpiece. 7. Rotate the spindle by clicking CW. 8. Select “X”, click “+” to drive the cutter automatically to find the edge. 9. The cutter will stop moving when it sticks onto the edge. Virtual CNC machining: Automatic edge-finding 2 3 4 9 5 1 6 8 7 Virtual CNC machining: Manual edge-finding 1. 2. 3. 4. Zero return Z-axis. Load the workpiece 1 (if not). Change to the cutter T5. Use JOG and Handle mode to Move the T5 cutter to the edge of the workpiece. 5. The alarm on T5 will turn red as soon as it reaches the edge. Virtual CNC machining: Over-travel alarm The over-travel alarm will be shown when any one of the axes is moved out of its range. This alarm could be released by changing to JOG mode and move back to the permissible range. Virtual CNC machining: Example Dimension and profile of this workpiece Virtual CNC machining: Example 1. 2. 3. 4. 5. Load the workpiece 1. Read the NC file “ex1.nc”. The G-code will be displayed onto the screen. Choose the MEM mode, and click “Cycle Start”. The tool path will be traced and shown onto the workpiece. Virtual CNC machining: Example G-Code of this example: G91 G28 Z0 G91 G28 X0 Y0 T10 M6 G90 G92 X-450.000 Y250.000 Z375.000 G0 X0. Y10. Z10. M08 M03 S1000 G1Z-4. F910. X43. X51. Y23.856 Y39. X68. Y18. X90. Y90. X40. X18. Y68. Y47. X30. Y35. X10. X24.434 Y10. Z20. M09 M05 M30 WE WLLL DISCUSS THE DETAILS IN THE NEXT CHAPTER!! Part2: Introduction of G-code G-code is a common name for the most widely used numerical control (NC) programming language, it is a language in which people tell computerized machine tools what to do and how to do it. 1. Which function is activated in machine? 2. Where to move to? 3. How fast to move? 4. Through what path to move? Operate CNC machines Begin in the form of punch tape Develop into computer chips in the 1970s Introduction of G-code Sample Program Block N1 M06 T1 ; Change to tool #1 Comment Comment separator Tool Number Miscellaneous code: Tool change Block Sequence # Introduction of G-code Sample Program Block N02 M03 S1500; Turn spindle on at 1500 rpm Spindle Speed: 1500 rpm Miscellaneous code: Turn spindle on Line Number Introduction of G-code Terminology • Block – A single line of code in an NC part program • Word – The programming expression formed when a letter (address character) is combined with a number • Address Character – A letter used in G & M code programming to designate a class of functions • Parameter – Attribute of a feature for geometrical information, such as a dimension, that can be modified N00 G90 G01 X.5 Y.5 Z0 F1 Introduction of G-code Address character • N – Sequence or line number • G – Preparatory function • M – Miscellaneous function • F – Feed rate (inches per minute or millimeters per minute) • S – Spindle speed (rpm – revolutions per minute) • T – Tool number • X, Y, Z – Distance (Relative Coordinates) or position (Absolute Coordinates) in X, Y, Z direction • I, J ,K – Circular cutting reference for X, Y, Z axis, respectively Introduction of G-code Preparatory: G Codes 1. G90 : Absolute Coordinates 2. G91 : Relative Coordinates 3. G92: Programming of absolute zero point. 4. G28: Move to Origin 5. G00 : Rapid Traverse (non-cutting move) 6. G01 : Straight Line Interpolation (cutting move) 7. G02 : Circular Interpolation (clockwise) 8. G03 : Circular Interpolation (counter-clockwise) 9. G04 : Dwell (wait) 10. G05 : Pause – Wait for user intervention Introduction of G-code Preparatory: G Codes X1Y2 R1 Absolute coordinates Example N001 G90 ; Absolute coordinates N002 G01 X1 Y2 ; start N003 G02 X2 Y1 R1; Circular Interpolation X2Y1 X1Y2 dy R1 dx Relative coordinates Example N001 G91; Relative coordinates N002 G01 X1 Y2 ; start N003 G02 dx dy R1 ; Circular Interpolation Introduction of G-code Miscellaneous: M Codes 1. 2. 3. 4. 5. 6. 7. M00 : Pause M01 : Sleep M03 /M04: Spindle on (CW/CCW). M05 : Spindle off M06 : Tool change M08 / M09 : Coolant on / off M10 / M11 : Vacuum on / off (Dust collection vacuum system turned on/off) 8. M30 : Program end and reset Introduction of G-code Suggestions • Same code is not required to be repeated every block, machine will use same code until changed • Tab remarks away from code to facilitate troubleshooting program • Specify absolute or relative coordinates and inch or metric modes at beginning of program • Move tool to safe position away from material before tool change command; change tool if necessary • Indicate spindle speed each time turned on Introduction of G-code Suggestions • Move tool to start position in two lines – First line moves in X-Y plane, then moves in Z axis (WHY?) • Raise tool up to position out of the stock at end of program • Always move table to safe unload position and turn spindle off at end of program • Use M30 command to end program Introduction of G-code Example 1- Absolute coordinates Absolute coordinates LABEL A B C D E F H I X 0.5 0.5 0.875 1.25 1.25 1.75 1.75 1.75 Y 0.5 1.5 1 1.5 0.5 1.5 0.5 1 Introduction of G-code Example 1- Absolute coordinates N0 G90 G20 N5 M06 T1 N10 M03 S3000 N15 G00 X.5 Y.5 N20 G00 Z.1 N25 G01 Z-.0625 F9 N30 G01 X.5 Y1.5 F18 N35 G01 X.875 Y1 N40 G01 X1.25 Y1.5 N45 G01 X1.25 Y.5 N50 G01 Z.1 N55 G00 X1.75 Y1.5 N60 G01 Z-.0625 F9 N65 G01 X1.75 Y.5 F18 N70 G03 X1.75 Y1.5 I1.75 J1 N75 G01 Z.1 N80 M05 N85 G00 Z2 N90 G00 X4 Y3 N95 M30 ; ABSOLUTE COORD & INCH MODE ; TOOL CHANGE – LOAD TOOL 1 ; TURN SPINDLE ON CW TO 3000 RPM ; RAPID TO POINT A ; RAPID TO .1 ABOVE PART ; PLUNGE 1/16 AT 9 IN./MIN ; STRAIGHT LINE INTERP TO B ; STRAIGNT LINE INTERP TO C ; STRAIGHT LINE INTERP TO D ; STRAIGHT LINE INTERP TO E ; RETRACT CUTTING TOOL ; RAPID TO POINT F ; PLUNGE AT 9 IN./MIN ; STRAIGHT LINE INTERP TO H ; CCW CIRCLE INTERPOLATION ; RETRACT CUTTING TOOL ; TURN OFF SPINDLE ; RAPID Z TO SAFE POSITION ; MOVE TABLE TO UNLOAD POSITION ; END OF PROGRAM Introduction of G-code Example 1 - Relative coordinates Relative coordinates LABEL X A 0.5 B 0 C 0.375 D 0.375 E 0 F 0 H 0 I 0 Y 0.5 1 -0.5 0.5 -1 1 -1 0.5 Introduction of G-code Example 1 - Relative coordinates N00 G90 G20 N5 M06 T1 N10 M03 S3000 N15 G00 X.5 Y.5 N20 G00 Z.1 N25 G91 N30 G01 Z-.1625 F9 N35 G01 X0 Y1 F16 N40 G01 X.375 Y-.5 N45 G01 X.375 Y.5 N50 G01 X0 Y-1 N55 G01 Z.1625 N60 G00 X.5 Y1 N65 G01 Z-.1625 F9 N70 G01 X0 Y-1 F16 N75 G03 X0 Y1 I0 J.5 N80 G01 Z.1625 N85 M05 N90 G90 N95 G00 Z2 N100 G00 X4 Y3 N105 M30 ; ABSOLUTE COORD & INCH MODE ; TOOL CAHNGE – LOAD TOOL 1 ; TURN SPINDLE ON CW TO 3000 RPM ; RAPID TO POINT A ; RAPID TO .1 ABOVE POINT A ; INCREMENTAL COORD & INCH MODE ; PLUNGE 1/16 AT 9 IN./MIN ; STRAIGHT LINE INTERP TO B ; STRAIGHT LINE INTERP TO C ; STRAIGHT LINE INTERP TO D ; STRAIGHT LINE INTERP TO E ; RETRACT CUTTING TOOL ; RAPID TO POINT F ; PLUNGE AT 9 IN./MIN ; STRAIGHT LINE INTERP TO H ; CCW CIRCLE INTERP ; RETRACT CUTTING TOOL ; TURN OFF SPINDLE ; CHANGE TO ABSOLUTE COORD ; RAPID Z TO SAFE POSITION ; MOVE TABLE TO UNLOAD POSITION ; END OF PROGRAM Introduction of G-code Example 2 – The previous example G91 G28 Z0 G91 G28 X0 Y0 M6 T10 G90 G92 X-450.000 Y250.000 Z375.000 G0 X0. Y10. Z10. M08 M03 S1000 G1 Z-4. F910. X43. X51. Y23.856 Y39. X68. Y18. X90. Y90. X40. X18. Y68. Y47. X30. Y35. X10. X24.434 Y10. Z20. M09 M05 M30 Ellipsis: Use the previous parameters Can you explain the code in red? http://reprap.org/wiki/G-code End of tutorial Thank you!