Lab 02: Manual Milling Operations

advertisement

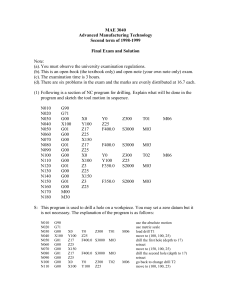

IENG 475 Computer-Controlled Manufacturing Systems 3/6/2016 Lab 05: CNC Lathe Programming I. Purpose A.) Provide an introduction to manual CNC programming B.) Provide experience designing and programming parts for production on the laboratory’s CNC equipment II. Practice Your lab team is to produce CNC turning program files for your project chess pieces in preparation for automated production. The CNC lathe is not currently programmable by using the MasterCAM program, since the dimensions of our parts are so small. You are to document the process in your engineering notes. The stock material for your chess pieces will be an acetyl plastic, approximately 3.9” long and 0.5” in diameter. At least one end of the stock will already be faced. 0.625” of the stock will be held within the chuck, and the parting operation will consume approximately 0.0875” of stock You will be doing the parting operation twice – following the plunge speed requirement will allow you to avoid an extra facing operation and further loss of stock material! You will only be able to get one pawn and another (tall) chess piece from each piece of stock. See the illustration, below. OVER-ALL LENGTH 3.900” CHUCKING USE 0.625” PARTING LOSS 0.0875” PARTING LOSS 0.0875” + X AXIS WORK PIECE ORIGIN + Z AXIS .025” CHUCK BUFFER >0.375” PAWN LENGTH ≤ 0.700” TALL PC LENGTH ≤ 1.000” Figure 1. Allocation of Stock Material and Workpiece Coordinate System. Depending upon your design, you may need to perform some of the following tools. The tools and their tool numbers are listed in the table below. Tool number 1 (T1) is used for the touch-off operation. All tool changes must take place 0.5” above the centerline of the workpiece and 0.5” from the end of the workpiece in the + Z direction. This lab will use absolute coordinates for all moves (except for circular interpolation center). Watch for tool holder clearance, plunge and feed rate limitations, and avoid rapid travel (G00) within the workpiece boundaries. 106748128 Page 1 of 5 Printed: 7:31 AM IENG 475 Computer-Controlled Manufacturing Systems 3/6/2016 Table 1. Tooling Magazine for Lab Tool T1 T3 T5 T7 Description Right hand profiling tool – 55 Diamond Insert (limit feed rate to 4 ipm) Grooving tool – Square Insert (90o, limit plunge depth to .05” at feed rate of 2 ipm) Left hand grooving tool – 55o Diamond Insert (limit feed rate to 4 ipm) Right hand parting tool - .085 wide (limit plunge feed rate to 1 ipm) o Note: Other tooling may be available – see instructor. Your first cut will be a roughing cut to obtain the maximum diameter of 0.400”. The lab instructor will provide you with the initial and final CNC code sections for your part(s) on the Materials page of the course website. Each person on the team is responsible for one CNC program for one of the chess pieces. Your team will need to come up with its’ own design for the project pawn, and this code portion will be standard for all individual programs within your team. Prepare your code using your CAD drawing for your chess piece(s) manually, and save the text of your final program as a MS Notepad file with the extension .NC on your floppy diskette. Bring a dimensioned view of your CAD file to the lab, along with your program on the diskette for review before production this week. Example Program for a Chess Piece. Note that the workpiece origin is on the centerline of the workpiece (and not at the top, right corner of the part!). % N100 G90 G80 G40 G00 N102 T1 M06 N104 G54 G00 X.1955 N106 F4 S1000 M03 N108 G00Z.5 N110 F4 G01 Z.1 N112 G01 Z-1. N114 G00 X.2662 Z-.9293 N116 G00 Z.02 N118 G00 X.1955 N120 G01 Z0. N121 G01 Z-.2 N122 G01 X.1 Z-.8 N123 G02 X.2 Z-.9 I0. K-.1 N124 G01 Z-1. N125 G00 X.5 Z-.9 N126 G00 Z.5 N127 T7 M06N128 G00 Z-.05 106748128 Keep all this code for your part programs! It performs the set-up for your program and the roughing cut. Roughing pass, leaving some material for finish Intermediate / Finishing passes Tool change code, use similar for your program Page 2 of 5 Printed: 7:31 AM IENG 475 N129 F2 G01 X.15 N130 F4 G01 X.2662 N131 G01 Z-.15 N132 F2 G01 X.15 N133 F4 G01 X.5 N134 G00 Z.5 N135 T3 M06 N136 G01 Z-1.0585 N137 F1 G01 X-.05 N138 F4 G01 X.5 M05 N139 G00 Z.5 N140 G28 N142 T1 M06 N143 M02 Computer-Controlled Manufacturing Systems 3/6/2016 Grooving plunge cuts at slower feed rate Tool change code, use similar for your program Parting cut at slowest feed rate Ending code, use same code for your program % Save your file to your disk space, and verify it with the TA / Instructor before cutting acetal! 106748128 Page 3 of 5 Printed: 7:31 AM IENG 475 Computer-Controlled Manufacturing Systems 3/6/2016 III. Setup This lab uses the Turning equipment located in located in CM 203. Access to the equipment on the following table may be required. Prepare this equipment prior to the start of the lab by making it generally accessible and cleaning any loose debris. Equipment/Material Listing Qty Description Location Notes (1) Lathe Workstation CM 203 Power on controller, load software, home machine. (1) Shop Vacuum CM 203 Connect to power, set up by Milling station. (2) Flat Mill Files CM 203 One at Mill, and one at Lathe. (2) .5” x 3.9” Acetal Rods CM 203 One set of white & black rods per student. IV. Safety Considerations The primary personal hazard during this lab exercise results from inadvertent operation of the equipment. Secondary hazards result from tooling and debris left in the lab area. The following actions are recommended: 1.) Check all powered equipment and load software prior to lab. All persons within the lab production area must have approved safety glasses/goggles on during the entire laboratory period. 2.) All personnel should be instructed to visually check for and remove debris from the equipment and work benches. 3.) All personnel should remain standing during the lab. Lab instruction steps should be checked off on the clip boards some distance from any operating equipment. 4.) At the conclusion of the lab, the equipment should be inspected, returned to normal condition, and loose equipment and tooling returned to storage. V. Lab Procedures The lab instructor should avoid admitting students to the lab until the previous group has completed their clean up and exited with their materials. The lab team (approximately four to five people to a team) are run through at the same time, with sub-teams simultaneously operating 106748128 Page 4 of 5 Printed: 7:31 AM IENG 475 Computer-Controlled Manufacturing Systems 3/6/2016 both the computers for coding and the lathe (for verifications). This lab may take more than 1 hour 20 minutes in total. Sequence of Activities for Each Lab: 1.) Introduce yourself, and the laboratory exercise. Distribute handouts, stock materials, and give any announcements. Students prepare their clip-boarded instructions and personal protective equipment. (2 min) 2.) The lab instructor guides the students through the general verification operation and safety on the Lathe. (10 min) 3.) Allow students to self-assign into two sub-teams of approximately equal size. Ask the student teams to take a minute or two to plan and organize themselves, then they should start their coding peg tasks on the computer equipment. Sub-teams rotate to the lathe to verify their code as they complete their tasks. (60 – 70 min) 4.) Encourage the team to assign one team member to compile a common program and verify it as the manual coding operations proceed. 5.) Ask students to wrap up their efforts and store their code in a couple of places for the team to access. Dismiss class. (7 min) 6.) Students complete their parts storage, 5S their station, replace safety equipment, gather materials, and exit the lab (5 min) Students should feel free to ask questions before operating equipment as the work progresses. The lab instructor should observe and coach students as necessary to ensure their understanding. At the conclusion of the lab, the lab instructor should return the lab materials, and report any items that need maintenance/replacement to the course instructor. If the lab will not be used inbetween sections, the materials may be left neatly in place. VI. Grading This assignment will become part of the final project. There is NO lab write-up required for this lab, but the code will be listed in the project. The instructor will check for completion of each individual’s workpieces by the due date. 106748128 Page 5 of 5 Printed: 7:31 AM