Seminar Co-processing of Hazardous Waste organised by SEPA

advertisement

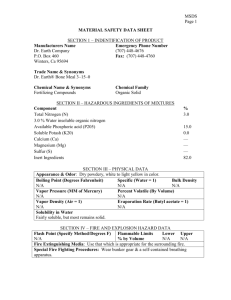

Workshop organised by SEPA, the Norwegian Embassy, GTZ and international cement industry “Co-processing of Hazardous Waste and Alternative Fuels & Raw Materials in Cement Kilns” “Hazardous Waste Management – Experiences from Norway” by Environmental Counsellor Inger Johanne Wiese, Norwegian Embassy Kempinski hotel, Beijing 12 May, 2005 Ladies and gentlemen, On behalf of the Norwegian Embassy I will welcome you to this seminar on co-prosessing of hazardous waste. In particular, I will underline the positive response provided by State Environmental Protection Administration (SEPA) and the German institution for development cooperation, GTZ, for this joint co-operation effort together with the Embassy. Special thanks to the Norwegian Center for Industrial and Technologial Research (SINTEF) as well as international cement industry for their contribution, respectively to the programme and the financing. We are also very happy that SEPA together with China Research Academy of Environmental Sciences (CRAES) took responsibility for the technical arrangements. In my speech I will focus on the challenges and the experiences in Norway with regard to hazardous waste management. Serious water and air pollution in Norway in the 1960s led to establishment of the Ministry of Environment in 1972. In Norway our environmental policy is based on inter alia two important principles; the Precautionary Principle and the Polluter Pay’s Principle. The Precautionary Principle states that where environmental and health risks relate to irreversible problems, such as toxic substances and global warming, one should not have to wait for full scientific certainty before taking action. The Polluter Pay’s Principle underlines that all polluters should pay for their external effects, such as polluted water, air and soil. These principles are reflected in our laws, regulations and economic instruments. Hazardous waste contains chemicals that are hazardous to the health and environment, because it contains toxic, inflammable, corrosive or other hazardous chemicals. With increasing production and consumption world wide, and not at least in China, there is also a strong growth in waste in general and in hazardous waste as well. In Norway, we have experienced a considerable increase in the amounts of hazardous waste, especially generated by the offshore industry in the 1990s. The effects of hazardous waste are extremely harmful to the environment. Arctic research shows that air borne POPs substances are accumulated in the food chain and threatens reproduction of polar bears, and it can therefore also threaten the environment of our children. It is therefore a national target in Norway that practically all hazardous waste is to be dealt with in a proper way. This implies that it should either be recycled or treated within Norway. It is important for Norway to work towards reducing emissions of hazardous chemicals and waste, being a recipient of air borne hazardous toxic substances in the Arctic region. We are particularly concerned with the most hazardous global pollutants, such as the persistent organic pollutants (the POPs) and mercury. 60% of the global emissions of mercury stem from Asian countries, mainly India and China, and coal power production is a major source. These pollutants do not only have harmful effects locally, but also globally. In Norway, mercury pollution in fish mostly comes from long-transported pollution from other parts of the world. Norway is therefore a strong supporter of international co-operation in reducing chemical risks. I would like to underline that Norway greatly welcomes the fact that China ratified the Stockholm Convention on Persistent Organic Pollutants, November last year and that several multilateral institutions like UNDP, UNIDO, GEF and the World Bank is engaged in the work related to SEPAs development of a National Implementation Plan. Last week, the first Conference of the Parties took place in Uruguay. I am informed that the meeting went well, and many necessary decisions to make the Convention an effective instrument to eliminate POPs were taken. China played an active and constructive role in the meeting as a Party to the Convention. Among other things, China will co-chair an expert group on best available techniques, one of the two groups set up by the Conference of the parties. Incineration of waste Also incineration of waste – which is the topic of this workshop - could lead to the release of chemicals hazardous to the health and environment, dust and emissions contributing to acid rain and climate change. Such emissions could lead to long term and serious environmental damages and influence peoples health if no strict regulations are in place. The most serious environmental impact caused by incineration is due to emissions to air of heavy metals like cadmium, mercury and lead, and of toxic organic compounds like PAH and dioxins. The total releases to the environment depend on e.g. waste containing hazardous chemicals are separated before incineration, the quality of the incineration process, and the quality of the purification of the effluent gases. Figures show that emissions in Norway of dioxins, mercury and cadmium from incineration have been substantially reduced since 1990 to 2002, by between about 70 % - 90 %1 or more per unit (kg) incinerated. These reductions are a result of stricter national discharge levels for all incineration operations. New and better technology for purification and incineration has made the reductions in emissions possible. Measures implemented The incineration operations must be licensed according to the national regulation of waste. The regulation regulates all incineration of waste and hazardous waste. From 2004 the authorities changed the tax on final disposal of waste. The tax was previously levied per ton of waste incinerated and related to the use of the energy produced. The new tax depends on the operations’ emissions to air. It is expected that the new regulation will motivate to even further reductions in emissions from the incineration operations. We expect further reductions in emissions towards 2006, when all incineration operations will have to apply to even stricter national discharge levels. These stricter discharge levels are based on the EU directive on incineration of waste. All incineration operations have effluent gas purification to reduce or prevent emissions to air. Fly ash and mud are residual products from the purification process. In addition, there will be residuals of slag and bottom blow after the incineration. When residual products like slag and ash from incineration operations are deposited, it could lead to releases of hazardous waste to water. Residual products from the incineration of waste are hazardous wastes and should therefore be placed in special landfills for hazardous waste. Hazardous waste management - experiences Today we have better knowledge of the properties of hazardous substances and the products they are used in, than earlier. This has led to an increase in the amounts of waste that are classified as hazardous waste. For instance, bottom ash and slug from incineration operations has been considered hazardous waste from 2003. We have also become aware that old insulating windows contain such high amounts of PCB that they are classified as hazardous waste when they are to be disposed of. Another example is the return schemes that provide 1 90 % for dioxins, 73% for cadmium and 68 % for mercury consumers free delivery of electrical/electronic (EE) waste. Consumers may deliver their old personal computers, mobile telephones and so on to the distributors, who in turn are obliged to collect them. The harmful components are segregated for special collection. In the old days entire TV sets were simply dumped as household waste without removing the hazardous components. Today we know better! If hazardous waste is dumped with ordinary waste it may result in the dispersal of harmful substances in the environment. They may spread via seepage of contaminated water from landfills, or in the flue gases, ash or slag produced in the incineration process. Hazardous waste that is disposed in the sewage may cause increased pollution of sea and seabed due to malfunctioning of purifying plants. All sorts of measures are employed to promote proper handling of hazardous waste, including special regulations, inspections and audits, industry-specific schemes, return schemes, taxes and information. Regulations Under the Pollution Control Act the competent Norwegian authorities have issued regulations concerning hazardous waste. These define waste categories and lay down rules for permits to manage hazardous waste, the obligation to deliver hazardous waste, declaration, the responsibilities of the municipalities, packaging, inspection and audit. Many other provisions govern specific types of hazardous waste and associated problems, including batteries, waste oil, oily water, photographic chemicals, amalgam, PCBs, CFCs, brominated flame retardants, fire and explosion hazards, export and import, chemicals in general, warning labels and health, environmental and safety activities in enterprises as part of the Internal Control Regulations under the Pollution Control Act. Permits, control and inspection A permit is normally required from the competent pollution control authorities before a contractor may process hazardous waste. The Norwegian Pollution Control Authority issues permits for collection and processing of hazardous waste, while the provincial governor issues permits for the reception and temporary storage of hazardous waste. The permits specify criteria that must be met to ensure proper handling. The pollution control authorities supervise and inspect all handling of hazardous waste. Industry-specific schemes and taxation fees Various industry-specific schemes and taxes are also used for hazardous waste. One scheme provides a refund when waste oil is delivered to approved facilities. Another is an autoindustry return scheme for lead accumulators and old insulating windows containing PCB. Action Plan for twelve prioritised types of hazardous waste Statistics Norway estimates that about 800 000 tonnes of hazardous waste were generated in Norway in 2003. The fate of about 100 000 tonnes are unknown, and they may well have escaped proper treatment. The 100 000 tonnes of missing hazardous waste include waste oil and other oily waste, demolition waste containing PCB and impregnated wood. An action plan has therefore recently been adopted focussing on the twelve most dangerous types of hazardous waste. This includes waste that contains hazardous substances such as PCB, mercury and brominated flame retardants. All these substances are also included on the Norwegian List of Priority Substances, which is the Government's list of substances where we have national targets for reduction or elimination of releases. The most important measures are to: provide information and guidance prevent the generation of hazardous waste improve the established return schemes and consider whether there is a need to establish new schemes concentrate the inspections carried out by the provincial governor on hazardous waste containing substances included on the Norwegian List of Priority Substances promote the implementation of municipal waste plans on a nationwide basis increase the quality of environmental clean up operations. These measures will strengthen management systems of toxic substances at the national, regional and local level and also increase the awareness by NGOs, the public and business and industries. Let me finally underline that environmental challenges cannot be left to central environmental authorities alone. Environmental issues need involvement of provincial and local governments, but also business, industries, universities, NGOs and consumers. The huge challenges we are facing in the world especially related to hazardous waste must be integrated into economic, energy, and industrial policies. We need closer co-operation and more partnerships. The central government in China has an important role in providing the right incentives for action, through the 11th 5 year plan, laws, regulations, taxes, standards, public information etc. With the strong growth in the energy sector linked to strong economic growth, there is an urgent need to increase resource efficiency, recyle and minimise waste in the overall economy. We know that China has excellent human resources and can be very efficient in implementation. We also know there are many cost-effective measures that can be taken, that might also contribute to improvement in living conditions and public health. This is promising. However, the environmental issues are cross cutting issues. Coordination of many ministries and institutions as well as involvement of business, industries and civil society are therefore needed also with regard to hazardous waste. These are also demanding tasks, but our experience from Norway and Europe has taught us that information sharing, dialogue and public participation are important elements to get all relevant sectors on board and to achieve good results. I wish you a most successful seminar and I hope that the presentation of the technological possibilities by the researchers and business representatives will provide input to further policy development and measures. The overall aim is to contribute to a cost-efficient and environmentally sound way for treatment of hazardous waste. Thank you for your attention.