To:

advertisement

University of Notre Dame

Senior Design Studio

B19 Fitzpatrick Hall

Notre Dame, IN 46556

Phone: (574) 1 – BUTLER

Fax: (574) 9 - BUTLER

Email: ShopTheButler@gmail.com

Web: www.nd.edu/~me463b28

To: Dr. S. Batill, Dr. M. M. Stanisic

From: John A. Williams

Re:

Individual Trade Study

Date: 28 February 2008

Purpose

The purpose of this trade study is to determine the ideal container dimensions that

minimize container material based upon a set of constraints. The constraints acting upon this

container are trifold: the contact between the container and the conveyor belt must not slip, the

container must not tip over, and the packaging volume does not exceed 1.00 L. This trade study

is integral to the design of “The Butler” product, because if the containers are made to the ideal

specifications, it will cut down on material cost for supermarkets that choose to use the service.

Information Sources

The main source of analysis of information in this trade study is MATLAB. The

equations used in the MATLAB code itself were derived from two main sources of information.

The first source was The Tipping Box Problem by Professor M.M Stanisic. The second source

was the textbook Engineering Mechanincs: Statics by J.L. Meriam and L.G. Kraige. They are

will be annotated as (Ref 1) and (Ref 2) respectively hereafter. There were many assumptions

and set values that went into the engineering model, which are shown in the table below.

Known/Set Values

Gravitational Constant

Thickness of Container

Maximum Volume of Packaging

Assumed Values

Density of Container (polypropylene)

Density of Packaging

(coffee beans, dry dog food)

Static Friction Coefficient

Symbol

g

t

Vf

Value

9.81

0.1

1.00

Units

N/kg

in

L

ρc

ρf

0.85

0.4

g/cm3

g/cm3

μs

0.9

N/A

Table 1: Known and Assumed Values

1

Engineering Analysis

Dynamic Analysis

In order to determine the ideal dimensions of the container for product packaging, the

constraints on acceleration must first be determined. To solve the maximum acceleration that

prevents the container from slipping, a free-body diagram of an arbitrary container being pushed

by a conveyor belt must be drawn and labeled (shown below1).

In order to determine ax that causes slippage,

the forces must be summed in the x and y

directions.

F

f max

(1)

F

N W may 0

(2)

x

y

From Ref 2, static friction is at a maximum

when f s N . Therefore, from equations

(1) and (2) max slip sW . By recognizing

Figure 1: Free-Body Diagram of Container

that the weight of an object is its mass multiplied by the gravitational constant g,

ax slip

sW

m

s mg

m

s g . Therefore, the acceleration that causes the body to slip along the

conveyor belt is a constant solely dependent on the coefficient of static friction. From (Ref 2)

the coefficient of static friction between rubber and pavement is 0.9, and the friction between the

conveyor belt rubber and polypropylene container is assumed to be the same.

Now that the maximum acceleration before slipping is known, the maximum acceleration

before tipping can be determined. The same free-body diagram in Figure 1 can be used, but the

1

Adapted from Ref 1

2

length of d is now equal to s / 2. The force equations from the slipping condition remain the

same in the tipping case, but now the moment equation must be analyzed. Tipping is prevented

when the body doesn’t rotate, or the sum of the moments about the center of gravity of the body

is equal zero:

M

g

Nd f y I g 0

(3)

Using equations (1) and (2), equation (3) can be arranged as: Nd max tip y .

Solving for ax gives:

ax tip

mgd

m y

gd

.

y

(4)

The values of d and y can be determined based on the geometry of the container.

Geometric Analysis

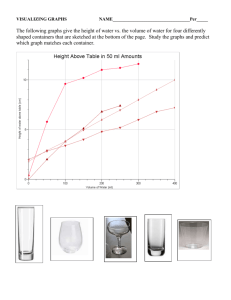

Two basic container shapes were analyzed for this study: a box with a square base, and a

cylinder (see below). It was assumed that each container had the same uniform thickness

throughout, was made of the

same material, and was

completely filled with the

packaging of a uniform density

(see Table 1). The value of d

can be obtained visually from

Figure 2 as s / 2 for the box

Figure 2: Vital Dimensions of Containers

and r for the cylinder. To

derive the value of y a more in-depth analysis is necessary. The y-coordinate of the center of

mass depends on the amount of packaging material in the container. The more material, the

higher the y-coordinate of the center of mass. By equation 4, as y increases, ax tip decreases.

3

Therefore the completely full container will tip easier. To find y , the container must be broken

down into three distinct parts: mf (the mass of the packaging material), mbot (the mass of the

bottom part of the container), and mrest (the mass of the walls of the container). From Ref 2, the

equation for the center of mass of a composite object is Y

my .

m

The equations below apply

for both the square based box and the cylinder:

Y

my m

m

ybot

t

2

yrest y f

f

y f mbot ybot mrest yrest

(5)

m f mbot mrest

(6)

h t h t

t

2

mf f Vf

2

mbot cVbot

mrest cVrest

For the box:

For the cylinder:

V f s 2t hbox t

V f r t hcyl t

Vbot s 2t

Vbot r 2t

2

Vrest s 2 hbox t s 2t hbox t

2

Vrest r 2 hcyl t r t hcyl t

2

2

Inserting the relationships back into the equation (5) gives the following.

h t

hbox t

2

2

2 t

2

f s 2t hbox t box

c s t c s hbox t s 2t hbox t

Ybox

2

f V f c s t c s hbox t s 2t hbox t

2

2

f r t hcyl t

Ycyl

2

2

2

2

hcyl t

hcyl t

2

t

c r 2t c r 2 hcyl t r t hcyl t

2

2

2

2

2

2

f V f c r t c r hcyl t r t hcyl t

4

In order to determine each y , the two unknowns are the height and critical length (h and

s or r). The height of the container can be determined based off the constraint that the packaging

is filled to the top of the container, or that Vf is constant. If Vf is constant, then from equation (6)

h is solely a function of s or r. Therefore, based on the condition of a constant volume of

packaging, the y-coordinate center of mass can be determined solely from the container’s critical

length. Since d is also solely dependent on the critical length of the container, the acceleration

needed to tip the container over ( ax tip ) can be determined from equation (4) for a given critical

length

Results and Discussion

Constraint Results

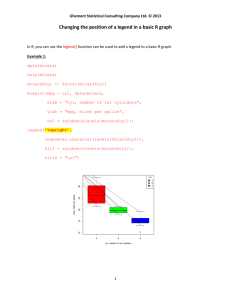

For the packaging volume of 1.00 L, the figures below show the minimum critical length

for each geometry.

Figure 3: Minimum Critical length to Avoid Tipping/Slipping

The minimum length of the side of the box is 10.01 cm and the minimum length of the cylinder

radius is 5.41 cm. These are the constraints for the container dimensions.

5

Measure of Merit

The universal measure of merit is efficiency. The most efficient container design

minimizes the amount of material to construct the container (volume of polypropylene) for a

given constant packaging volume. The figure below shows the volume of polypropylene used

based on the surface area of the container bottom (used to normalize the critical length).

From the figure, the surface area that minimizes the container material is 171.61 cm2 and 156.15

cm2 for the box and the cylinder respectively. Using the following simple equations,

SAbox s 2

SAcyl r 2

, s = 13.1 cm and r = 7.05 cm. From Figure (3) these critical lengths are greater than

the minimum lengths necessary to avoid tipping and slipping for both geometries.

6

Impact

This study determined that the ideal container for the product packaging system has a

radius of 7.05 cm, a height of 7.15 cm. This container will neither slip nor tip whether it is

empty, completely full (1.00 L of packaging), or anywhere in between. This study determined

that the maximum acceleration that the container can maintain without slipping (or tipping) is

approximately 8.8 m/s2 (equation 1). This acceleration can be put to positive use by determining

the torque and speed requirements for the conveyor belt motor. If the distance of the entire

assembly line process is known, and bang-bang control is used to move the conveyor belt (half

of the distance between stations it is at maximum acceleration and the other half it is at

maximum deceleration) the velocity of the conveyor belt can be determined.

7

Appendix

MATLAB Code

%%%%%%%%%%%%%%%%%%%%%%

%% John A. Williams %%

%% AME 40463

%%

%% Trade Study Code %%

%% 2/28/08

%%

%%%%%%%%%%%%%%%%%%%%%%

%% BOX %%

% sumFx = f = m*ax

% sumFy = -W + N = m*ay = 0

% sumMg = N*d - f(ybar) = 0

mu_s = 0.9

%mu_k = 0.8

g = 9.81

t = 0.1 * 2.54

%assume thickness of 0.1 inches

%m = rho_cont*v_cont + rho_food*v_food

%rho_cont = 0.85 [g/cm3]

%rho_food = 0.4 [g/cm3]

r_c = 0.85*1000

r_f = 0.4*1000

%densities in kg/m^3

%vol_food = 1000 = (s-2*t)^2*(h-t)

%vol_cont = s^2*h - vol_food

v_f = 1000

%v_f = 0:10:1000

v_f_m3 = v_f*1*10^-6

%assume volume of 1 L = 1000 ml = 1000cm^3

8

s = [5:0.1:15]

%range of side length from 5 cm to 30 cm

h = (v_f./((s - 2.*t).^2)) + t

%v_c_cm3 = s.^2.*h - v_f

v_c_cm3 = s.^2.*t +2.*(h-t).*t.*s + 2.*(s-2.*t).*(h-t).*t

v_c = v_c_cm3 * 0.000001

m_c = r_c.*v_c

m_f = r_f.*v_f_m3

%m_f = 0

m = m_c + m_f

%MASS IN KG

y_rest = ((h+t) ./2)/100

y_bot = (t./2) / 100

y_f = y_rest

%y_f = 0

v_bot = (s.^2.*t) * 0.000001

m_bot = r_c.*v_bot

m_rest = m_c - m_bot

%ybar = (m_f.*y_f + m_c.*y_c) / m

y_bar = (m_f.*y_f + m_bot.*y_bot + m_rest.*y_rest) ./ m

W = m.*g

N = W

f = mu_s.*N

a_slip = f./m

d = ((s/2)/100)

a = g.*d./y_bar

plot(s,a,s,a_slip)

xlabel('s (cm)')

ylabel('a (m/s^2)')

legend('Tipping Acceleration', 'Slipping Acceleration')

title('Acceleration vs. Side Length of a Box')

%% CYLINDER %%

r = [2:0.1:12]

h_cyl = (v_f./(pi.*(r - t).^2)) + t

%v_cyl_cm3 = pi.*r.^2.*h_cyl - v_f

v_cyl_cm3 = pi.*r.^2.*h_cyl - (pi*((r-t).^2).*(h_cyl-t))

v_cyl = v_cyl_cm3 * 0.000001

m_cyl = r_c.*v_cyl

9

m_food = r_f.*v_f_m3

m_tot = m_cyl + m_food

y_f_cyl = ((h_cyl + t) ./2)/100

y_bot_cyl = (t./2) / 100

y_rest_cyl = y_f_cyl

v_bot_cyl = (pi.*r.^2.*t) * 0.000001

m_bot_cyl = r_c.*v_bot_cyl

m_rest_cyl = m_cyl - m_bot_cyl

y_bar_cyl = (m_food.*y_f_cyl + m_bot_cyl.*y_bot_cyl + m_rest_cyl.*y_rest_cyl)

./ m_tot

d_cyl = r./100

a_cyl = g.*d_cyl./y_bar_cyl

W_cyl = m_tot.*g

N_cyl = W_cyl

f_cyl = mu_s.*N_cyl

a_slip_cyl = f_cyl./m_tot

figure

plot(r,a_cyl,r,a_slip_cyl)

xlabel('r (cm)')

ylabel('a (m/s^2)')

legend('Tipping Acceleration', 'Slipping Acceleration')

title('Acceleration vs. Cylinder Radius')

%% Merit Graph %%

%v_foody = [100:100:1000]

sa_cyl = pi.*r.*r

sa_box = s.*s

figure

plot(s,v_c_cm3)

figure

plot(r,v_cyl_cm3)

figure

plot(sa_cyl,v_cyl_cm3, sa_box, v_c_cm3)

xlabel('Surface Area of Bottom (cm^2)')

ylabel('Volume of Polypropylene (cm^3)')

legend('Cylinder', 'Box')

title('Volume of Polypropylene vs. Surface Area of Bottom')

10