Energy Loss by Charge Paticles in Matter

advertisement

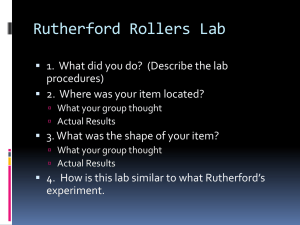

PART II LABORATORY 11 ENERGY LOSS OF ALPHA PARTICLES PASSING THROUGH MATTER 11.1 MOTIVATION The purpose of this practical is twofold. On the first day the energy loss of alpha particles (helium nuclei) passing through matter will be investigated experimentally, and the energy loss relationship will be used to measure the thickness of various commercial aluminium foils. On the second day you will gain experience with the use of ultra high vacuum (UHV) equipment, and use this equipment to manufacture your own thin aluminium foil. UHV equipment is important in many areas of experimental physics, and this section is designed to give you an appreciation of the practical issues involved in producing and maintaining UHV equipment. 11.2 BACKGROUND As alpha particles pass through matter they loose energy due to both electrostatic interactions with electrons in the matter and excitation of electrons into unoccupied energy levels, and it can be shown that the energy lost per unit distance due to such interactions with the matter is given by1 2 dE 1 2 NZe4 3 me v 2 ln dx 4 o me v 2 I Eq. 11.1 where I is the mean excitation and ionisation energy of matter of atomic number Z , me is the mass of an electron, v is the velocity of the alpha particle, and all other symbols have their usual meaning. Noting that the majority of the terms in Eq. 11.1 are simply constants we can simplify this expression to dE c1 ln c2 E dx E Eq. 11.2 where we have introduced the variable E m v 2 denoting the incident energy of the alpha particle (the me term having been subsumed into the constants c1 and c2 ). If the material is sufficiently thin that the energy loss is small compared to the total energy (as is the case for a thin foil) the log term in Eq. 11.2 is almost constant over the foil thickness and Eq. 11.2 can be approximated as E k Eq. 11.3 m T E where E is the energy lost and E the incident energy of the particle passing through the foil, T is the foil thickness, and both k and m are constants which are a property of the foil material. Taking the logarithm of both sides of Eq. 11.3 we get logE log k logT m log E Eq. 11.4 thus if we plot a graph of E as a function of E on a log-log graph for a foil of given thickness T we get a straight line (recall that the constants k and m are properties of the material). Reversing this argument, we can work out the foil thickness T from a log-log graph of E as a function of E provided we know the constants k and m for the foil material. This is the technique used here for determining the thickness of unknown foils. 1 A detailed theoretical derivation of the energy lost passing through matter is not important to this practical. 100 ENERGY LOSS OF ALPHA PARTICLES PASSING THROUGH MATTER 11.3 MEASUREMENT OF UNKNOWN FOIL THICKNESS Figure 11.1 Schematic layout of detector electronics In this section you will use the relationship relating foil thickness to energy loss, Eq. 11.4 of section 11.2, to measure the thickness of several aluminium foils. The basic concept behind this experiment is fairly simple: the schematic layout of the experiment is shown in Figure 11.1 with a detail of the detector chamber shown in Figure 11.2. Alpha particles from a radioactive source, in this case 226Ra, are pass through a foil before striking a solid state energy sensitive detector, the geometry of this system being such that all particles incident on detector must have passed through the foil 2. The charge pulses from the detector are amplified first by a preamplifier then a linear amplifier before being passed to a multi-channel analyser card located in a desktop PC. Because of the short range of alpha particles in air it is necessary to conduct the experiment in an evacuated chamber at a pressure of 10-3 torr or less. In order to measure the energy lost by alpha particles passing though the aluminium foils it is first necessary to calibrate the relationship between alpha particle energy and channel number on the multi-channel analyser (MCA). We can then use this information to determine the thickness of the unknown foils. 2 The detector used here is of the same type as the solid state detector used in the Rutherford experiment, to which students are referred for details of the how the detector works. 101 PART II LABORATORY Figure 11.2 Detail of detector chamber 11.3.1 DETECTOR CALIBRATION a) Setting up the equipment Look around your bench. Identify all the equipment shown Figure 11.1 and Figure 11.2, and follow the cables to see what is connected to what. Turn on mains power to all equipment except the vacuum pump one by one: this includes the NIM bin containing the amplifier modules, the CRO, and the PC. Let the equipment warm up for a few minutes (this enables the electronics to stabilise and helps make sure your readings don’t drift during the experiment). Open up the detector chamber by lifting off the lid using the two brass handles and inspect the inside, making sure that the 226Ra source is in place. (If the lid is hard to remove you may have to Emitted Particle Energy (keV) loosen one of the air inlet valves first, making sure 7687.1 that the vacuum pump is switched off first). Identify 6002.6 5489.7 the source, detector, and the slot for the foil holder. 5305 Replace the lid on the chamber, close the air inlet 4748.5 valve, and turn on the vacuum pump. When the 3280 pressure in the chamber has dropped below 10-1 1161 Torr slowly raise the detector bias to 90V. 690 We now have to set the gain on the amplifier so that 170 the amplifier output falls within a useful detection Table 11.1 and particle energies range of the MCA card. The MCA card digitises emitted by 226Ra. voltages in the range from 0 volts to 10V into 1024 channels, and from the table of alpha particle energies in Table 11.1 we know that we have to be able to detect alpha particles of at least 7700keV. To ensure enough dynamic range you should therefore adjust the amplifier gain set so that the 7687keV peak falls at about 9V when viewed on the CRO. Note your final amplifier settings. 102 ENERGY LOSS OF ALPHA PARTICLES PASSING THROUGH MATTER Signals from electronics Start acquire: <Alt-1> Stop acquire: <Alt-2> Clear MCA: <Alt-3> Swap view: <F4> MCA card Save: <Alt-F><Alt-S> PC memory Move data from MCA to PC: <Alt-5> <Print Screen> <Print Screen> Restore: <Alt-F><Alt-R> Move cursor: Left/Right arrows Fast movement: PageUp/PageDown Toggle expanded view: <F3> Change expanded view region: Keypad +/Change vertical scale: Up/Down arrows Figure 11.3 Summary of MCA commands b) Setting up the data acquisition software Make sure the PC with the MCA card is switched on and start the MCA program by typing mca at the command prompt. (yes, this is a DOS based program but it works as well as its modern counterparts. Who needs a graphical interface anyway?) Review the MCA command list (see Figure 11.3) and try the following: - Start collecting a test spectrum (Alt-1). You should see a series of dots creeping up on the screen - let this run for about 1 minute or so. - Stop acquisition (Alt-2) and transfer your data from the MCA card into the computer’s buffer memory (Alt-5), then save the data (Alt-F, Alt-S) into a temporary file. You can only save data in the buffer, but can only acquire data from the MCA card, thus you must always transfer the data from the MCA to the buffer (Alt-5) before saving. Many a student has wasted hours by saving the wrong spectrum in the wrong file, so be careful. - Move the cursor using the left and right arrow keys. Note that a counter at the bottom of the screen changes as you do this: this indicates which channel number the central line is located over. Note that Page-up and Page-down move the cursor quickly from one place to another. - Adjust the vertical scale from logarithmic to linear (Up arrow): at first the spectrum will disappear, but keep going until the spectrum reappears. To return to a logarithmic scale keep hitting the down arrow key. - Change to expanded view (F3) and move the cursor around again. Now change the size of the expansion region using Keypad +/- and note that you can get the cursor resolution down to single channel units. Note the counter on the left indicating the detector dead time. It takes the MCA card a few milliseconds to digitise the incoming pulse during which time no further incoming pulses can be measured. The dead time measures the amount of time the MCA is digitising data relative to the amount of time it is waiting for incoming data. Check that the is less than 10% and, if not, adjust your experimental parameters. Briefly inspect your spectrum with reference to the alpha particle tabulated in Table 11.1 and check that it looks like what you would expect. If you are at all unsure about whether your spectrum looks OK check with your demonstrator now. 103 PART II LABORATORY c) Calibrating the detector We are now in a position to calibrate the relationship between MCA channel number and energy. First, collect a spectrum for about 10 minutes. There is nothing magical about this figure: the longer the count time the better the spectrum, but the more time you have to spend waiting for data collection. 10 minutes is a reasonable compromise, but feel free to choose some other time if you think it appropriate. After the spectrum has been collected save the file, print one copy for each member of your group by pressing the <print screen> key, and record the channel numbers of all features using the MCA program. Question (a) Identify which features are due to the alpha particles and which are due to the beta particles (where do the beta particle peaks appear?) and, using only the alpha particle data, determine the relationship between channel number and energy for your electronic settings. Remember to include uncertainties for all measurements. 11.3.2 MEASUREMENT OF THE THICKNESS OF ALUMINIUM FOILS. At this point we would usually get you to determine the relationship between energy loss and foil thickness, m and k from Eq. 11.4, for a given material. However this is a tedious and timeconsuming process so instead we will give you the relationship, determined from previous experimental data collected using your equipment, and let you use it to determine the thickness of a number of aluminium foils. A calibration plot obtained from previous experimental data for a 12m thick aluminium foil is shown in Figure 11.4. Note how, when plotted on log-log axes, the data appears as a straight line, and that fitting a straight line to this data enables us to determine m and k 3. Title: Graphic s produc ed by WAVE Creator: WAVE Version 6.05 (OSF1 ax p) Prev iew : This EPS picture w as not s av ed w ith a preview inc luded in it. Comment: This EPS picture w ill print to a Pos tSc ript printer, but not to other ty pes of printers. Figure 11.4 Calibration of energy loss vs energy for 12m thick aluminium foil 3 Note that if we let x log 10 E and y log 10 E we can recast Eq. 11.4 in the form where c log 10 k log 10 T . For a given material will be manifested as differences in the value of y mx c k and m are constant, thus differences in thickness c. 104 ENERGY LOSS OF ALPHA PARTICLES PASSING THROUGH MATTER Armed with this information we are in a position to determine the thickness of unknown foils by measuring the energy lost by the alpha particles as they pass through the foil. On your bench you will find a selection of aluminium foils of different thickness, a small sample of which can be located in the foil holder mount between the 226Ra source and the detector. Table 11.1 you know the energy of the alpha particles incident on this foil and, by measuring the spectrum with the foil in place, you can determine the energy lost by the alpha particles as they pass through the foil (simply Ein – Eout). By plotting these two on log-log scales you can work out the thickness of the foil by comparing the gradient and intercept values with those of a 12m foil presented in Figure 11.4. 11.4 MANUFACTURING A THIN FOIL The purpose of this section is to introduce you to the operation of ultra-high vacuum (UHV) equipment through the manufacture of a thin aluminium foil by evaporation. UHV systems are commonly used in experimental physics thus it is essential that you have an appreciation of how they work – your report should therefore aim to demonstrate an understanding of UHV technology and how to use it. Manufacturing the thin foil and measuring its thickness takes up all of today’s lab session so it is essential that you start on the foil manufacture as soon as you get into the lab. There are lengthy periods of waiting during the foil manufacture process which you might like to use to answer some of the questions if you have not had time to do so already. Feel free to discuss the questions on vacuum technology with your demonstrator. 11.4.1 INTRODUCTORY READING The book Vacuum Technology by Roth is available from the part 2 office and answers many of the questions in this section. You might like to sit down in comfortable location and quickly read the following sections. This is not meant to be an arduous task and there is much more detail in the text than you need. In particular DO NOT transcribe large slabs of the book, in fact don’t even bother sitting down and taking slabs of notes – rather, skim read the text and briefly answer the questions (no more than one paragraph per point). If you have any questions do not hesitate to discuss them with your demonstrator. a) Sections 7.1 and 7.2: Materials and cleaning techniques b) Chapter 5: Pumping techniques Read Section 5.1: Introduction, pp. 200-203; Section 5.2.4: Rotating vane pumps, pp. 206-212; Section 5.2.8: Molecular pumps, pp. 217-220; Section 5.3.3: Diffusion pumps, pp. 223-232; Section 5.6: Cryopumping, pp. 248-263 c) Chapter 6: Measuring low pressures Read Section 6.1: Classification of vacuum gauges, pp.280-282; Section 6.3.1: Manometers, pp. 285-287; Section 6.6: Thermal conductivity gauges, pp. 304-310; Section 6.7: Ionisation gauges, pp. 310-325. The section on sealing techniques is also particularly interesting if you have time to read it. 11.4.2 FOIL MANUFACTURE We will use the technique of evaporation to manufacture a thin foil. To do this the source material (aluminium) is placed on a metallic boat made of heat resistant material such as 105 PART II LABORATORY Basic rules for operating a high vacuum system When starting a mechanical pump first ensure that the rotor moves in the correct direction and that the oil level is correct. Always vent a mechanical pump to atmospheric pressure when the power is off. The presence of a residual vacuum in the pump frequently causes oil to be drawn into the casing or vacuum system. Do not permit a mechanical pump to exhaust a high-vacuum system below a pressure of a few hundred microns unless the pump is separated from the high-vacuum chamber with a trap stopping the oil vapour from entering the chamber. Always keep the inside of a high vacuum system clean. In particular, grease from fingers can result in considerable contamination and gloves should always be used when handling anything destined for the inside of high vacuum equipment. Do not run a mechanical pump at high pressures for long periods of time. The motors are not generally designed for long term use with the additional load, and the pump will eject much oil in addition to gas. Diffusion pumps should be cooled to a safe intermediate temperature before being vented to atmosphere. Venting at too high a temperature results in oxidation of the pump fluid and excessive carryover of the fluid into the mechanical pump. Always check that the cooling water supply to diffusion and turbomolecular pumps is turned on prior to operation. It is also a good idea to have thermal protection to guard against interruption to the cooling water supply. In liquid nitrogen trapped systems the trap should be cool enough to condense the diffusion pump oil prior to turning on the diffusion pump. Maximum backstreaming of pump oil occurs during startup and shutdown of the diffusion pump. Do not vent a liquid nitrogen trap to air whilst cold. When the chamber is vented to atmospheric pressure it is advisable to use a dry, inert gas such as nitrogen to minimise moisture adsorption on the surface of the vacuum system. Never vent from the foreline of a diffusion pump. Ionisation gauges, in particular hot cathode gauges, should not be turned on until the pressure is below 10-3 Torr. titanium which is heated by passing an electric current through it. The source material itself sits within a depression in the boat which is thinner than the surrounding material – it thus has a higher resistance relative to the rest of the circuit and heats up the fastest. This heats the source material to boiling, at which point the vapour expands in a hemisphere above the boat condensing on whatever surfaces it first strikes. Because the material is heated to boiling point it is essential that this procedure be conducted under high vacuum so that the source material does not oxidise. A schematic diagram of the evaporation chamber is shown in Figure 11.5. The evaporation takes place inside a glass bell jar which is evacuated by a diffusion pump and a rotary pump. Next to the evaporation chamber is a high-current power supply consisting of a variable 240V, 10A to 3V, 80A step down transformer connected to the boat clamps via 150A cables. Note that the bell jar is very expensive (˜$2600) and should only be handled by your demonstrator, and that the perspex shield should always be placed around the bell jar when it is evacuated to guard against shrapnel in the unlikely event of an implosion. Inspect the vacuum chamber and identify all components. If the bell jar has not already been removed get your demonstrator to remove it now. Also locate the titanium boat, aluminium sample, and the foil holder with a thin mylar film in it. The titanium boat will have been handled by hand, therefore it is necessary for you to clean it prior to placing it in the vacuum chamber. After putting on one of the latex gloves provided gently clean the boat using isopropyl alcohol and one of the lint free tissues 106 ENERGY LOSS OF ALPHA PARTICLES PASSING THROUGH MATTER provided. The titanium is quite brittle and will easily snap, so be careful whilst doing this. Once clean carefully place the titanium boat in its holder in the evaporation chamber being careful not to touch it with bare hands. Pre-lab Question (a) Why is it important to keep the inside of a high vacuum system clean? What is the effect of contaminants such as sweat and grease from hands on the vacuum system, and how can contamination from such sources be minimised? Pre-lab Question (b) What are the desirable properties of the material from which a vacuum chamber should be made? What sort of materials have these properties? Pre-lab Question (c) What is outgassing and how can the outgassing rate of a vacuum chamber be reduced? Locate the 0.5g aluminium slug and place it in the boat, once again making sure that it is clean of all grease. Find and locate the holder with the mylar foil, on which the aluminium will be deposited. This will also have been handled by hand so you will have to clean it with isopropyl alcohol before placing it in the vacuum chamber as you did for the titanium boat. Once clean, mount the foil holder in the clamp approximately 7cm above the boat: if you place it too close (<6cm) the mylar will melt during evaporation whilst if it is too far away (>9cm) the aluminium layer will be too thin to be interesting. Inspect the inside of the vacuum chamber for any accidental fingerprints. If you find any, clean them away with alcohol before replacing the bell jar. (Also remember to make sure that the perspex implosion shield is in place before pumping down the system). Pre-lab Question (d) Note the rubber seal on the bell jar. Briefly describe the main means of sealing a vacuum chamber. What are the most common types of vacuum seal, and what are the main parameters which define the useful range of a particular vacuum seal? Figure 11.5 Schematic diagram of vacuum system In order to reduce the pressure to <10-4 Torr we have to use the diffusion pump, which requires us to first pump the bell jar down to 10-2 Torr. To do this first close all of the air inlet valves, check that both the baffle and backing vales are closed, then open the roughing valve. Switch on the rotary pump and wait until the pressure in the bell jar has dropped below 10-2 Torr, then open the backing valve and turn on the diffusion pump heater. Pre-lab Question (e) Describe the operation of a rotating vane pump (otherwise known as a rotary pump, which is the main type of vacuum pump used in the nuclear labs). What defines the lowest pressure at which a rotary pump can operate? What is the function of gas ballast in a rotary pump? Is there any advantage to be gained from connecting two pumps in series and, if so, why? 107 PART II LABORATORY Pre-lab Question (f) Briefly describe the principle behind the diffusion pump (the second type of vacuum pump you will use today). What is meant by roughing and backing, and why are these necessary when using a diffusion pump? Why is it necessary to cool a diffusion pump? What is the effect of having no cooling? What is a cold trap and why might it be useful in combination with a diffusion pump? Pre-lab Question (g) Briefly describe the principle behind the turbo-molecular pump (a common pump used in experimental laboratories). What limits the ultimate pressure to which a turbo pump can operate? Do turbo pumps require backing by another pump and, if so, why? Pre-lab Question (h) Describe the process by which cryopumping operates. How is its action different that of mechanical and diffusion pumps? What is the useful range of pressures over which cryopumping can be used? Pre-lab Question (i) vacuum pump? What are the main parameters which define the useful range of a Once the diffusion pump has heated up (about 15 minutes) close the roughing valve, open the baffle valve (think about what would happen if you forgot to close the roughing valve first!), and watch the pressure drop below what could be achieved with the rotary pump alone. Comment on any rapid fluctuations in pressure during this pumping procedure. Pre-lab Question (j) How does a thermistor gauge measure vacuum pressure? What is the difference between a Pirani and thermistor gauge (both of which are commonly used in modern laboratories)? Over what range of pressures can thermal conductivity gauges be used? Pre-lab Question (k) On what principle does an ionisation gauge work (these are also commonly used in modern laboratories)? In particular what is the difference between hot and cold cathode gauges? Over what pressure range are ionisation gauges useful? Pre-lab Question (l) What is the definition of a Torr, the most commonly used unit of pressure measurement in vacuum systems? (The term Torr originates from the Torricelli vacuum above a column of mercury in a sealed glass tube.) When the pressure has dropped below 10-5 Torr you can start the evaporation. First turn on the evaporation power supply and raise the current until the boat glows bright red (about 5070A). When the aluminium has melted slowly increase the current until the boat glows white hot and you can see the bell jar being coated with aluminium. Continue evaporation until you can see that all of the aluminium has been evaporated (about 2 minutes). You have now made the foil and can proceed to bring the bell jar back up to atmospheric pressure. First close the baffle valve, then turn off the diffusion pump heater. The bell jar is now isolated from all pumps so you can use the air inlet closest to the bell jar to bring the chamber back up to atmospheric pressure. When the diffusion pump has cooled (about 20 minutes) you can close the backing valve, turn off the rotary pump, and bring the vacuum side of the rotary pump to atmospheric pressure using the right most air inlet valve. Question (b) Comment on why you have to let the diffusion pump cool before turning off the backing pump, and on why you should leave the inlet of the rotary pump at atmospheric pressure. What would happen if you failed to do this? 11.4.3 MEASUREMENT OF FOIL THICKNESS Congratulations – you now have a thin aluminium foil of your own making. All that remains to be done is to measure its thickness. To do this repeat the procedure used yesterday to measure the foil thickness, section 11.3.2 above, making sure that the mylar side of the foil is towards the 226Ra source. Compare your measured value with what you would expect if all of the 0.5g aluminium slug had been evaporated – Aluminium has a density of 2.7g/cm3 and during the evaporation this uniformly coats a hemisphere of radius equal to the boat-mylar distance, from which you can calculate the expected foil thickness. 108 ENERGY LOSS OF ALPHA PARTICLES PASSING THROUGH MATTER But there is a catch – the alpha particles have passed through both the aluminium and the mylar, not just the aluminium. The energy lost by alpha particles passing through the mylar is small but measurable and can be taken into account. Question (c) Work out how you could take the effect of the mylar into account and, if you have time, perform the necessary experiments. (Hint: there is a second, identical mylar foil available should that be of any use.) Also remember to quote uncertainties on all results so that you can properly assess whether your measured thickness is in agreement with what you would expect from the mass of aluminium evaporated. 11.5 REFERENCES Roth, A., Vacuum Technology, 3rd Edition, (Elsevier Science B. V., Amsterdam, 1990) 109