properties of rubber compounds containing

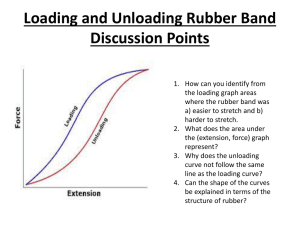

advertisement

HEXAMETHYLENE-N,N’BIS(TERT-BUTYL PEROXYCARBAMATE) AS A CROSSLINKING AGENT FOR NATURAL RUBER AND NATURAL RUBBER/POLYBUTADIENE BLEND D.S. OGUNNIYI* DEPARTMENT OF CHEMISTRY, UNIVERSITY OF ILORIN, ILORIN, NIGERIA And C. HEPBURN INSTITUTE OF POLYMER TECHNOLOGY AND MATERIAL ENGINEERING UNIVERSITY OF TECHNOLOGY, LOUGHBOROUGH, LE11 3TU. UNITED KINGDOM. ABSTRACT The results of technological evaluation of hexamethylene-N,N’bis(tert-butyl peroxycarbamate) (HBTBP) as a crosslinking agent for natural rubber and natural rubber/polybutadiene rubber blend are presented. Similar studies were carried out using sulphur and peroxide systems as controls. The cure characteristics were evaluated with the Monsanto Oscillating Disc Rheometer while tensile sheets were prepared and stress-strain measurements in simple extension were used to characterize the mechanical properties of the vulcanized elastomers. It was found that the properties obtained with the various systems decrease in the following order: sulphur > peroxide > HBTBP. The cure mechanism of HBTBP in natural rubber and the blend was explained as occurring thorough the free radical process. Key Words: natural rubber, polybutadiene, blend, crosslinking/vulcanization, HBTBP. *CORRESPONDING AUTHOR INTRODUCTION A major advancement to the use of rubber was the discovery of vulcanization by Charles Goodyear in the U.S. in 1839 and, by Thomas Hancock in the U.K. in 1844 (1). Since the time of Goodyear and Hancock, vulcanization has remained an important area of rubber compounding technology. From a historical perspective, vulcanization is the process of heating rubber, sulphur and white lead (2). Crosslinking, which is the process by which a network polymer is formed, is also referred to as vulcanization and/or curing. It must be noted however, that curing is also applied to processes which may not involve crosslinking since curing is defined as changing the properties of resin or rubber formulations by chemical reaction usually under the action of heat and varying conditions of pressure (3,4). Sulphur remains the most widely used vulcanizing agent for polydienes including natural rubber (4). For example, in accelerated sulphur vulcanization, there is greater control over the process especially by minimizing modulus and tensile strength reversion so that vulcanizates with specified physical properties are readily obtained. Also, the physical appearance and physical properties are good in accelerated systems. In addition to sulphur vulcanization systems, rubbers can be crosslinked by peroxides. Peroxide vulcanization of rubber has been reviewed recently in the literature (5,6). Some obvious advantages of peroxide vulcanization are non-reversion during cure and good ageing resistance when long cure times are employed. Another characteristic of peroxide system is that saturated rubbers (e.g. silicone rubber) can only be crosslinked by peroxides. When diene-containing rubbers are crosslinked by peroxides, the properties of vulcanizates obtained are inferior to those of vulcanizates cured by sulphur. Nevertheless, peroxide vulcanizates of these diene rubbers, and indeed of other rubbers may be desirable in applications where creep resistance is required. Crosslinking is also effected by radiation, the use of resins, metal oxides and other miscellaneous vulcanizing agents. Among the miscellaneous vulcanizing or crosslinking systems are the bisperoxycarbamates. Hepburn (7) reported the use of bisperoxycarbamates as crosslinking agents in gum natural rubber. Also, the use of HBTBP as crosslinking agents for fluoroelastomers has been reported in the literature (8,9). Furthermore, the results of technological evaluation of HBTBP in many elastomers have been reported (10). Therefore, it was decided that HBTBP should be evaluated in natural rubber (NR) natural rubber/polybutadiene (NR/BR) practical compounds. NR/BR blend was used because it is customary to use BR in many blends to enable it improve abrasion resistance, crack resistance, to improve processing and to confer many of its desirable properties to the blend. In particular, sidewalls of passenger tyres are commonly based on blends of nearly equal proportions of natural rubber and polybutadiene (11). The subject matter of this paper is the technological evaluation of NR and NR/BR blend in different crosslinking systems. EXPERIMENTAL Materials The elastomers used, natural rubber (NR, SMR 5 CV ) produced by Malaysian Natural Rubber and cis-polybutadiene (BR Intene 50) produced by Enichem Corporation, were obtained from commercial sources. Also, other compounding ingredients were standard materials used in rubber formulations and were used in compounding as received. HBTBP was prepared as described in the literature (12). Mill Mixing The mixing of the various rubber batches was on a two-roll mill of 850cm3 capacity. The mixing procedures adopted were along the guidelines set in British Standards (BS) 1674; 1976. After the elastomer was first masticated on the mill, activators and other ingredients were added and blended thoroughly. Mooney Test The principles laid down in BS 1673 Part 3, 1969 were followed in the determination of Mooney scorch i.e. use of a large rotor, 1 minute preheat time, test temperature of 120oC and scorch time was taken as 5 Mooney units above the minimum reading. Cure Characteristics The cure characteristics of the compounds were studied with the aid of a Monsanto Oscillating Disc Rheometer TM 100, using the test procedure specified in BS 1673; Part 10, Method B, 1977. Moulding The compression moulding techniques specified in BS 1674; 1976, were used to obtain vulcanized rubber sheets of 2mm thickness. Tensile Stress-Strain Tests The tensile stress-strain properties of the resulting vulcanizates were determined according to BS 903; Part A2, 1971, using Type 2, dumb-bell specimens. Other tests Other tests included tear strength, which was determined according to BS 903 part A3, 1982; rebound resilience, which was determined according to DIN 53512; hardness test, which was determined according to BS 903 Part A26, 1969 and compression set measurement which was determined according to the guidelines of BS 903 Part A6, 1969. RESULTS AND DISCUSSION Curing Characteristics The Oscillating Disc Rheometer (ODR) traces obtained when HBTBP cure is compared with those of conventional systems (used as controls) in NR and NR/BR are shown in Figures 1 and 2. The ODR cure traces obtained shows that HBTBP is capable of crosslinking compounds of NR and NR/BR blend. The two elastomer systems investigated are diene-based and in both systems, sulphur vulcanization system gave the best cure response while HBTBP gave the least cure response; peroxide vulcanization systems were intermediate. The rate of cure of HBTBP cure is intermediate between those of sulphur and peroxides. Interestingly, there is no tendency to reversion in HBTBP systems on overcure. Our observations of the cure systems in this work were similar to what was observed previously in other elastomers (10). The Mooney scorch for HBTBP cures were very short and this observation is further supported in the HBTBP cures shown in Figures 1 and 2. Some of the HBTBP compounds produced a rather unpleasant odour during curing. As it is usual with HBTBP cures, the compounds must be cured longer than t95 cure times to ensure that the carbon dioxide evolved during cure is sufficiently absorbed by the calcium hydroxide system. It was further observed that the maximum torque attained in the NR/BR blend was greater than when NR was used alone in all the curing systems. This may be due to a peculiarity of BR, which undergoes spontaneous crosslinking during vulcanization. In sulphur vulcanization systems, BR requires less sulphur than other diene rubbers to obtain the optimum crosslink density (13). Physical Properties of vulcanizates The results of physical properties of vulcanizates prepared from HBTPB compounds, sulphur compounds and peroxide compounds are shown in Tables 1 & 2. The physical properties of vulcanizates cured with conventional crosslinking agents were better than those obtained from vulcanizates cured with HBTBP. Further compounding studies with HBTBP would be needed to make its vulcanizates comparable to those obtained from conventional crosslinking systems. The ageing of vulcanizates was carried out under relatively mild conditions (24 hours at 100oC in air cell oven) and the vulcanizates used as controls were protected with antioxidant while HBTBP-cured systems were unprotected. It was found that the retention of tensile properties in most HBTBP systems was better than those of the controls after ageing. This may be an indication that air-oven ageing may be useful in improving physical properties in this instance. The compression set for HBTBP-cured vulcanizates was extremely poor, as samples did not show any recovery. This suggests that the crosslinks originally formed were thermally unstable. However, the compression set of HBTBP-cured blend was better than HBTBP-cured natural rubber vulcanizates. The improvement in compression set resistance may be due to the spontaneous crosslinking of polybutadiene rubber. Also, further compounding studies would be required to improve the compression set resistance of HBTBP-cured vulcanizates. Cure Chemistry Detailed studies on cure chemistry have not been carried out in this work. However, NR and NR/BR vulcanizates cured with HBTBP were extracted with hot acetone and after removal of solvent, these vulcanizates were tested for nitrogen. The extracted vulcanizates were found to contain nitrogen. This suggests that nitrogen, probably from amino groups, is attached to the polymer main chain of the elastomers. This finding is similar to that of Hepburn (7) who proposed a free radical mechanism for the crosslinking of gum natural rubber by bisperoxycarbamates. In this mechanism, it was proposed that the bisperoxycarbamate decomposes homolytically; as the initiator decomposes, the free radicals formed abstract hydrogen from the methylene groups along the polymer chain, and the resultant polymer radicals interact, directly or through the intermediary of radical traps to form crosslinks. It was also suggested that both flexible crosslinks and carbon-carbon crosslinks are formed from the interaction of polymer radicals. The same mechanism as proposed by Hepburn (7), is thought to apply in the present work where HBTBP is used as crosslinking agent for filled NR and NR/BR compounds. Conclusion This work has established that HBTBP is capable of curing filled natural rubber and natural rubber/polybutadiene compounds. Although the physical properties of vulcanizates cured by conventional crosslinking systems were found to be better than vulcanizates cured by HBTBP, HBTBP-cured vulcanizates tend to have good retention of properties on heat ageing. The mechanism of crosslinking of NR and NR/BR is proposed to occur through homolytic decomposition of HBTBP, interaction of radicals with rubber, interaction of the resultant rubber radicals, directly or through the intermediary of radical traps and subsequent formation of crosslinks. References 1. Hoffmann, W., “Vulcanization and Vulcanizing Agents” Maclaren, London, England. 1967. 2. Sjothun, I.J. and Alliger, G. in “Vulcanization of Elastomers”, I.J. Sjothun and G. Alliger (Eds.) Robert E. Frieger Publishing Company, Huntington, New York. 1978. p3. 3. Gillam, J.K. in “Encyclopedia of Polymer Science and Engineering” J.I Kroschwitz (Ed.), Wiley, New York. Vol.4 1986. p519. 4. Quirk, R.P.,”Overview of Curing and Crosslinking of Elastomers” Prog. Rubber Plast. Technol. 4(1) 31, 1988 5. Ogunniyi, D.S., “Peroxide Vulcanization of Rubber” Prog. Rubb. Plast. Technol. 15(2) 95, 1999. 6. Dluzneski, P.R., “Peroxide Vulcanization of Elastomers” Rubb. Chem. Technol. 74(3) 451, 2001 7. Hepburn, C., “Bisperoxycarbamates: vulcanizsing agents that possess bound antioxidant properties” Rubb. World 190 49, 1984 8. Ogunniyi, D.S. and Hepburn C., “Hexamethylene-N,N’ bis(tert-butyl peroxycarbamate as a curing agent for fluoroelastomers” Plast. Rubb. Process. Appl. 6(1) 3, 1986 9. Ogunniyi, D.S., “A Novel System for Crosslinking Fluoroelastomers. Rubb. Chem. Technol. 61(5) 735, 1988. 10. Ogunniyi, D.S. and Hepburn C., “Hexamethylene-N,N’ bis(tert-butyl peroxycarbamate as a crosslinking agent in some elastomers” Iran J. Polym. Sci. Tech. 3(1) 48, 1994 11. Kim, H.J. and Hamed, G.R., “On the reason that passenger tyre sidealls are based on blends of NR and cis polybutadiene” Rubb. Chem. Technol. 73 743, 2000 12. Pedersen, C.J., “Preparation and Properties of esters of N-substituted peroxycarbamic acids” J.Org. Chem. 23 252, 1958 13. Blow, C.M. and Hepburn, C., “Rubber Technology and Manufacture” 2nd edition. Newnes-Butterworths, London. 1982 Table 1: Comparison of physical properties of NR vulcanizates obtained using HBTBP crosslinking agent and controls NR SMR 5 CV ZnO CaO Ca(OH)2 Stearic Acid SRF Black (N762) Coumarone Resin CBS Flectol H Sulphur Dicup 40C HBTBP Mooney Scorch at 120oC Cure Conditions (mins/ oC) Unaged Properties Tensile Strength (Mpa) 300% Modulus (Mpa) Elongation-at-break (%) Tear Strength (kN/m) Hardness IRHD Rebound Resilience (%) Aged Properties (24 hours at 100 oC Tensile Strength (Mpa) 300% Modulus (Mpa) Elongation-at-break (%) Tear Strenth (kN/m) Compression Set %(24 hours at 100 oC; 25% strain) % Retention of Tensile Strength Sulphur (phr) Peroxide (phr) HBTBP (phr) 100.0 100.0 100.0 5.0 5.0 4.0 6.0 2.0 30.0 30 30 5.0 2.0 1.0 0.5 1.5 1.5 6.0 40 mins > 40 mins 2 mins 9/160 14/170 10/150 23.54 5.12 600 89.43 36 63 17.37 10.68 525 27.93 36 57 4.97 4.07 375 8.75 < 36 - 21.55 5.99 525 63.37 46 14.81 9.88 550 23.42 32 5.17 3.11 400 16.89 - 92 85 104 Table 2: Comparison of physical properties of NR/BR vulcanizates obtained using HBTBP crosslinking agent and controls NR SMR 5 CV BR Intene 50 ZnO CaO Ca(OH)2 Stearic Acid SRF Black (N762) Coumarone Resin CBS Flectol H Sulphur Dicup 40C HBTBP Mooney Scorch at 120oC Cure Conditions (mins/ oC) Unaged Properties Tensile Strength (Mpa) 300% Modulus (Mpa) Elongation-at-break (%) Tear Strength (kN/m) Hardness IRHD Rebound Resilience (%) Aged Properties (24 hours at 100 oC Tensile Strength (Mpa) 300% Modulus (Mpa) Elongation-at-break (%) Tear Strength (kN/m) Compression Set %(24 hours at 100 oC; 25% strain) % Retention of Tensile Strength Sulphur (phr) Peroxide (phr) HBTBP (phr) 50.0 50.0 50.0 50.0 50.0 50.0 5.0 5.0 4.0 6.0 2.0 30.0 30 30 5.0 2.0 1.0 0.5 1.5 1.3 6.0 45 mins > 45 mins 2 mins 12/160 12/170 10/150 14.31 6.08 525 25.74 39 67 6.35 3.97 400 8.67 40 68 4.39 3.18 400 10.95 35 58 9.9 7.31 375 18.05 36 5.48 3.70 375 9.77 16 4.26 2.71 425 10.49 53 69 86 97