IEE 572 DESIGN OF ENGINEERING EXPERIMENTS

advertisement

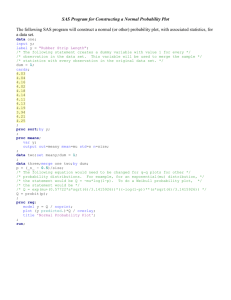

IEE 572 DESIGN OF ENGINEERING EXPERIMENTS FALL 2000 FINAL REPORT TERM PROJECT AN EXPERIMENTAL DESIGN FOR IMPROVING THE ACCURATE CLASSIFICATION OF THE IMAGES OF PRESENT AND ABSENT COMPONENTS IN PRINTED CIRCUIT BOARDS WHEN INSPECTED BY AN AUTOMATED VISUAL INSPECTION SYSTEM By PRAVEEN BABU SREENIVASULA REDDY KATHA LUIS MAR INTRODUCTION The current miniaturization of the assembly surface mounted devices (SMD) in Printed Circuit Boards (PCB) makes it a difficult task for human inspectors to determine their correct positioning and even their presence in the board. This task becomes even more difficult when the production cycle time for the PCBs is small, leaving the inspectors with not enough time to accurately complete their job. Figure 1: Picture of a PCB. Note the size of Components compared to a ten cents coin. The typical solution to this problem is the introduction of an Automated Visual Inspection (AVI) system to replace the human inspectors. The imminent advantage of these systems over human inspectors is their capability of reliably inspecting a large number of small components at a fixed level of performance for long periods of time [1]. Figure 2 describes a typical PCB assembly line: 1 Glue Dispenser Machine Placement Machine 2-D Inspection System PCB Feeder Nozzle (Pipette) Figure 2. PCB Assembly Line A bare PCB enters the glue dispenser where glue is placed to the positions in the board where components will later be mounted. The next operation is the placement of the SMD to the board. This operation is performed by chip-shooters which operate in tandem (placement machine). The components are fed to the chip-shooter by a feeder, which is an array of rolls containing the components to be placed in the PCB. Once the components have been fed to the chip-shooter it places them on the board using vacuum nozzles. After the components have been placed on the board the AVI machine inspects the presence and correct placement of the components. [2] The Electronics Assembly Laboratory (EAL) at Arizona State University is developing an integrated quality environment for SMD assembly. This environment consists of several modules that interact with each other to determine in real time the quality of the assembly process for SMDs and hence the quality of the product. These modules are: 2 Inspection Allocation Module (IAM) Quality Monitoring Module (QMM) Inspection Module (IM) The IAM instructs the different inspection systems as to which elements to inspect considering the total available inspection time, the inspection time required by each component and the needs of the QMM among others. The QMM uses the information provided by the IM to determine if the SMD assembly process is in state of statistical quality control. The inspection module (Figure 3) is in charge of the acquisition, in real time, of the process information. It consists of four Pulinix TM 440 monochromatic cameras with a resolution of 510x480 pixels, two IAI actuators operated by servomotors controlled by a Pentium II computer to move the cameras and an illumination system composed of a set of eight rails of approximately sixty-six LEDs each. The inspection module receives from the IAM a list of components to inspect and an algorithm to use to perform the inspection. Since one of the objectives of inspection allocation is to get as much information as possible without increasing the inspection cycle, the components to be inspected are only a fraction of the total number of components of the board. 3 Set of cameras Servo motors Set of LEDs Conveyor PCB Figure 3: Side view of AVI system PROBLEM DEFINITION AND FACTORS TO BE CONSIDERED The images rendered by the inspection system are the basis for the decision making of the entire quality control system. In order for these images to be useful they must provide sufficient level of detail so that the location, inspection and control chart plotting algorithms can make a decision. This decision consists of determining whether the components are present or absent and if they are present, determining their location and angle of rotation with respect to an ideal position within the board. The quality of the image provided by the cameras in every inspection routine depends greatly on three factors: Iris opening of lenses. Angle of illumination of the LEDs. Variation of current to manipulate the frontal illumination intensity. 4 The present set up of these factors is leading to an overlap of the populations of present and absent components as rendered by a classification algorithm that uses values such as energy, correlation and diffusion of the image captured by the cameras. The algorithm generates statistical values for present and absent populations, which can be plotted on histograms (Figure 4 & 5)[3]. When the image is not accurate there is an overlapping of these histograms that leads to a component classification error, that is, the value obtained from the algorithm falls in the range of both the present and absent population (Figure 5). Figure 4: Classification Algorithm 5 Overlapping of populations 2 50 2 00 1 50 P re s e n t A b se nt 1 00 0 o 0 M 6 1 5 1 3 2 re 0 0 5 0 0 0 0 0 0 0 5 0 0 1 1 2 50 1 0 0 9 5 7 6 0 5 5 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 4 0 3 1 5 0 0 0 0 0 0 0 50 Overlapping of populations 2 00 1 50 P re s e n t A b s e nt 1 00 M o re 25 0 2 30 2 10 1 90 17 0 15 0 1 30 1 10 90 70 50 30 10 0 -1 0 50 Figure 5: Histograms of present and absent populations of components When a component cannot be classified none of the quality control techniques can be applied to decide whether the process is in or out of statistical control. This creates a general failure of the system. SELECTION OF RESPONSE VARIABLE The values obtained from the classification algorithm for present and absent populations are calculated using three different inputs, which are energy, correlation and diffusion all of which are obtained from the image rendered by the inspection. For 6 the purpose of this experiment and in compliance with the request of the AVI system administrator, we focused on the energy factor. After an inspection routine is performed, a report file, which contains information regarding energy, is generated. Tables 1 and 2 show a sample of such reports. Table 1: Energy values for a present component. Component type Orientation Energy 805 V 1 805 V 2 805 V 40 805 V 125 805 V 125 805 V 29 805 V 84 805 V 69 805 V 81 805 V 54 805 V 157 805 V 157 805 V 157 805 V 39 805 V 68 805 V 45 805 V 42 Table 2: Energy values for an absent component. Component Type Orientation Energy 805 V 1 805 V 0 805 V 0 805 V 0 805 V 0 805 V 0 805 V 0 805 V 15 805 V 0 805 V 0 805 V 0 805 V 0 805 V 0 805 V 10 805 V 0 805 V 13 805 V 0 The component that was used as basis for the experiment was the most common component in the PCB, which is the 805 vertical component. The code for this component is used to identify capacitors, diodes and resistors that are placed in the PCB in the vertical coordinate. The information of energy was then used to calculate histograms to represent the energy distribution of the population of present and absent components. The overlapping of these populations can be estimated by subtracting the mean of each population. The response variable to be monitored will then be : 7 Z=( Mean(P)-Mean(A)) Where: Z= Mean distance of present and absent populations P= Present Components. A= Absent Components. The desired response will be a large (positive) value of Z. To obtain the values of energy for the present and absent populations the experiments will be performed twice at each factor combination of the experiment, one over a board with present components and one in a board without components. FACTOR LEVELS AND RANGES The factor levels and ranges will be as follows: 1. Iris Opening: (1.6 stop number x 2.8 stop number) 1.6 high level, 2.8 low level 2. Angle of illumination (90 45) 90 high level, 45 low level 3. Variation of current to manipulate the intensity level of frontal illumination (.6A I .3A) .6A high level, .3A low level. The numbers given in the range and levels of factor #1 refer to stop numbers on the 25mm focal distance TV lenses that are used by each of the cameras in the vision system where the lower the stop number the grater the opening of the iris. 8 According to the AVI administrator the assumption of linearity in the factor effects is not clear specially in the Iris opening factor because when going from one stop number to the other the opening varies according to a constant (π/4)*D2 , in other words, not linear. The use of center points will allow us to check for this nonlinearly effect. The values for the center points will than be: Iris opening: 2.2, Angle: 67.5, Current: 0.45 A. Four center points are used. DESIGN OF TEST MATRIX The design of the experiment to find the appropriate settings of the parameters described in the last section in order to obtain a optimum image from the inspection machine require the development of a test matrix of the different factor combinations. The design of this matrix involves the following main issues: Number of factors Levels of factors Number of replications Decision on Blocking Run order Power of the test (1-β ) Since the number of factors of interest for the experiment is 3, we have adopted 23 design, with 3 replications (refer to Table 4) and 4 center points. 9 The blocking technique was not considered to this experiment because none of the factors (or the experiment itself) was affected by any nuisance source of variation. The PCB boards belong to the same batch, no human interaction is related to the inspection routine that renders the image of the population of components within each PCB. The run order was determined by Design Expert software, the complete test matrix is shown in Table 3: Std 27 22 4 17 14 8 12 1 21 26 19 9 6 16 3 2 11 7 24 23 18 5 25 10 20 13 15 28 Run 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 Block Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Factor 1 Factor 2 Factor 3 Response A:Iris Opening B:Angle, Degrees C:Current, Amps Overlap, pixels 2.2 67.5 0.45 2.8 90 0.6 2.8 45 0.3 2.8 45 0.6 1.6 45 0.6 1.6 90 0.3 2.8 90 0.3 1.6 45 0.3 1.6 90 0.6 2.2 67.5 0.45 1.6 90 0.6 1.6 90 0.3 2.8 45 0.3 2.8 45 0.6 1.6 45 0.3 1.6 45 0.3 2.8 90 0.3 1.6 90 0.3 2.8 90 0.6 2.8 90 0.6 2.8 45 0.6 2.8 45 0.3 2.2 67.5 0.45 2.8 90 0.3 1.6 90 0.6 1.6 45 0.6 1.6 45 0.6 2.2 67.5 0.45 Table 3: Test Matrix 10 The results table for a number of replicates=3 is shown in Table 4: Term StdErr** A 0.2041 B 0.2041 C 0.2041 AB 0.2041 AC 0.2041 BC 0.2041 ABC 0.2041 VIF 1 1 1 1 1 1 1 Power at 5 % alpha level for effect of Ri-Squared 1/2 Std. Dev. 1 Std. Dev. 2 Std. Dev. 0 21.1 % 63.3 % 99.6 % 0 21.1 % 63.3 % 99.6 % 0 21.1 % 63.3 % 99.6 % 0 21.1 % 63.3 % 99.6 % 0 21.1 % 63.3 % 99.6 % 0 21.1 % 63.3 % 99.6 % 0 21.1 % 63.3 % 99.6 % Table 4: Results table The result table shows 99.6 as the percentage alpha level of all effects at 2 standard deviations from the mean, which is sufficiently accurate in terms of this experiment. PERFORMING THE EXPERIMENT The run order (random) and combination of factor levels provided by design expert was followed and the results rendered are shown in Table 5 in the Appendix. While running the experiment the most difficult factor to vary was the current of the LED panels because of the lack of accessibility presented by the layout of the machine. While changing the Iris opening an adjustment to the focus of the camera was also required to provide a clear image in the monitor, this adjustment (or the check for a proper image) was required each time the iris opening was changed from one level to the next. The variation of the angle factor was the one that did not present any major difficulty. The computation of the 11 response variable in each run was performed by the method described earlier in this report. STATISTICAL ANALYSIS OF THE DATA The statistical analysis of the response variable and the interpretation of the results derived form this analysis was performed by using the Design Expert® software. Tables 5 to 8 as well as graphs 1 to 7 are presented in the Appendix. Table 5, Table 6 show the Run matrix with responses and Design summary respectively. The highest order interaction term was assumed as the error term. The half normal plot (Graph1) clearly shows that A, C, AC are the significant factors. Taking the significant terms as the main effects and the remaining terms as error terms refines the model. The degrees of freedom for the model are 3, for curvature 1 and for the error are 24. The analysis of variance table (Table 7) provided by Design Expert ® shows the p values, the F values, Degrees of freedom, Sum of squares and Mean square terms. The high value of the model F-value is strong evidence that it is significant. According to the Design Expert ® report, there is only a 0.01% chance that a "Model F-Value" this large could occur due to noise. It is important to mention that as shown by Graph 5 (plot of residuals Vs. current) the assumption of homogeneity of variance seems not to hold. This happens even after data transformation has been applied to the data (Square root transformation with constant k=2 as suggested by Design Expert® when observations seem to follow a 12 Poisson distribution). However, due to the high value of the F ratio MS Model (2512. MS E 23), the effects of non-constant variance will be very unlikely to alter the results obtained by the experiment. More over, since the experiment was a balanced fixed effects model the results are only slightly affected when the assumption of constant variance is violated [4]. The analysis also found that there is evidence of significant second-order curvature in the response as measured by difference between the average of the center points and the average of the factorial points over the region of exploration. Regression Equation obtained from Design Expert® is as shown below. Final Equation in Terms of Coded Factors: Sqrt(Overlap + 2.00) 3.671378879 -1.19246518 1.330008522 -0.367902103 = *A *C *A*C Final Equation in Terms of Actual Factors: Sqrt(Overlap + 2.00) = 0.006802504 -0.14793145 * Iris Opening 17.85988601 * Current -4.087801148 * Iris Opening * Current According to Design Expert® the lack of fit is not significant relative to the pure error. This result suggests that this model is adequately fitted by the regression equation. 13 Residuals and Model Adequacy: The Graph 2 shows the plot of Normal probability vs studentized residuals .The assumption of normality is satisfied after the square root transformation.We have considered the square root transformation since the observations in this model follows the poisson distribution as our response deals with counting the number of components on the PCB board and this is also suggested by Design Expert® BOXCOX plot. The Graphs 3 and 4 shows the plots of residuals vs. predicted values and residuals vs. run order. These graphs show that the independence assumption on the errors has not been violated and also shows that there is no nonconstant variance. Graphs 6 and 7 are the plots of response surfaces. These graphs suggests that the response increases with the increase of the increase in Current and Iris opening .The interaction between these significant factors can be seen from the curvature of the response surface. The R-Squared value of 0.9969 shows that the proportion of the variability in the data is mostly explained by the model. Also, the "Pred R-Squared" and the"Adj R-Squared" values of 0.9956 and 0.9966 respectively are in reasonable aggreement with each other. Because the "Adeq Precision" ratio (which measures the signal to noise ratio) is 116.000 this model can be used to navigate the design space [4].The PRESS value of 0.36 suggests that the model for the experiment can be used in a new experiment to predict the response confidently. 14 CONCLUSIONS AND RECOMMENDATIONS The identification of the light intensity of the LED panels (current factor), the iris opening of the lenses of the cameras and their interaction as the significant factors in controlling the clarity of the image used by the AVI system, will lead to an increase of accuracy and efficiency in the calibration process of the inspection machine. The maximum value obtained for the difference in mean energy value for present and absent populations (42.8 pixels) was obtained when the Iris factor was in the high level (1.6 step numbers) the Current factor was in the high level (0.6 Amps) and the angle factor was in the low level (45°). It is then recommended to run the inspection machine at these levels. The significance of the non-linearity between the high and low levels of the factors (especially iris opening) needs to be taken into account when adjusting the levels in future research to optimize the response variable defined in this experiment and as suggested by Graphs 6 and 7. 15 REFERENCES 1. Muñoz, L., et al, Multivariate On-line Quality Monitoring of SMD Assembly, Working Paper, The University of Texas At El Paso,1999 2. Villalobos, J. and Verduzco, A., Integration of Quality and Process Planning Activities in SMD Assembly, Working Paper, The University of Texas at El Paso,1997 3. Arellano, M. and Villalobos, J., Vector Classification of SMD Images, Working Paper, Arizona State University,1999 4. Montgomery, D.C. (2000), Design and Analysis of Experiments,5th Edn, John Wiley & Sons, New York. 16 Appendix 17 Table 5: Run matrix with response. Std 27 22 4 17 14 8 12 1 21 26 19 9 6 16 3 2 11 7 24 23 18 5 25 10 20 13 15 28 Run 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 Block Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Block 1 Factor 1 Factor 2 Factor 3 Response A:Iris Opening B:Angle, Degrees C:Current, Amps Overlap, pixels 2.2 67.5 0.45 17.904 2.8 90 0.6 9.33 2.8 45 0.3 0.367 2.8 45 0.6 9.64 1.6 45 0.6 40.77 1.6 90 0.3 8.37 2.8 90 0.3 0.321 1.6 45 0.3 8.351 1.6 90 0.6 39.82 2.2 67.5 0.45 18.79 1.6 90 0.6 37.77 1.6 90 0.3 7.585 2.8 45 0.3 0.279 2.8 45 0.6 11.38 1.6 45 0.3 7.73 1.6 45 0.3 8.36 2.8 90 0.3 0.262 1.6 90 0.3 7.76 2.8 90 0.6 9.9 2.8 90 0.6 9.08 2.8 45 0.6 9.78 2.8 45 0.3 0.282 2.2 67.5 0.45 16.64 2.8 90 0.3 0.294 1.6 90 0.6 43.27 1.6 45 0.6 42.035 1.6 45 0.6 42.8 2.2 67.5 0.45 17.09 Table 6: Design Summary Study Type Factorial Initial Design 2 Level Factorial Center Points 4 Design Model 3FI Response Name Y1 Overlap Factor A B C Name Iris Opening Angle Current Experiments Blocks 28 No Blocks Units Pixels Obs 28 Minimum 0.262 Units Type Numeric Numeric Numeric Low Actual 1.6 45 0.3 Degrees Amps Maximum 43.27 Trans Square root High Actual Low Coded 2.8 -1 90 -1 0.6 -1 Model R2FI High Coded 1 1 1 18 Table 7: Analysis of Variance from Design Expert® Response: Overlap Transform: Square root ANOVA for Selected Factorial Model Analysis of variance table [Partial sum of squares] Sum of Mean Source Squares DF Square Model 79.82994798 3 26.60998266 A 34.12735695 1 34.12735695 C 42.45414405 1 42.45414405 AC 3.248446983 1 3.248446983 Curvature 1.957086139 1 1.957086139 Residual 0.243620098 23 0.010592178 Lack of Fit 0.046068325 4 0.011517081 Pure Error 0.197551773 19 0.010397462 Cor Total 82.03065422 27 Std. Dev. Mean C.V. PRESS 0.102918308 3.779310906 2.723203008 0.362336946 Coefficient Factor Estimate Intercept 3.671378879 A- Iris Opening-1.19246518 C-Current 1.330008522 AC -0.367902103 Center Point 0.755524183 DF 1 1 1 1 1 Constant: 2 F Value 2512.229517 3221.939472 4008.065513 306.6835669 184.7671089 Prob > F < 0.0001 < 0.0001 < 0.0001 < 0.0001 < 0.0001 1.107682007 0.3818 R-Squared Adj R-Squared Pred R-Squared Adeq Precision 0.996957547 0.996560705 0.995582908 116.0000076 Standard Error 0.021008112 0.021008112 0.021008112 0.021008112 0.055582239 95% CI Low 3.627920289 -1.23592377 1.286549932 -0.411360693 0.640543561 95% CI High 3.714837 -1.14901 1.373467 -0.32444 0.870505 significant significant not significant VIF 1 1 1 1 Final Equation in Terms of Coded Factors: Sqrt(Overlap + 2.00) 3.671378879 -1.19246518 1.330008522 -0.367902103 = *A *C *A*C Final Equation in Terms of Actual Factors: Sqrt(Overlap + 2.00) = 0.006802504 -0.14793145 * Iris Opening 17.85988601 * Current -4.087801148 * Iris Opening * Current 19 Table 8: Diagnostics Case Statistics Standard Order 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 Actual Value 3.217297002 3.218695388 3.119294792 1.538505769 1.510629008 1.509635718 3.12409987 3.220248438 3.095965116 1.514595656 1.503994681 1.523482852 6.635887281 6.539877675 6.693280212 3.657868232 3.411744422 3.43220046 6.30634601 6.728298448 6.466838486 3.366006536 3.328663395 3.449637662 4.317406629 4.559605246 4.461389918 4.369210455 Predicted Value 3.165933434 3.165933434 3.165933434 1.51680728 1.51680728 1.51680728 3.165933434 3.165933434 3.165933434 1.51680728 1.51680728 1.51680728 6.561754685 6.561754685 6.561754685 3.441020118 3.441020118 3.441020118 6.561754685 6.561754685 6.561754685 3.441020118 3.441020118 3.441020118 4.426903062 4.426903062 4.426903062 4.426903062 Residual Leverage 0.05136357 0.05276195 -0.0466386 0.02169849 -0.0061783 -0.0071716 -0.0418336 0.054315 -0.0699683 -0.0022116 -0.0128126 0.00667557 0.0741326 -0.021877 0.13152553 0.21684811 -0.0292757 -0.0088197 -0.2554087 0.16654376 -0.0949162 -0.0750136 -0.1123567 0.00861754 -0.1094964 0.13270218 0.03448686 -0.0576926 0.16666667 0.16666667 0.16666667 0.16666667 0.16666667 0.16666667 0.16666667 0.16666667 0.16666667 0.16666667 0.16666667 0.16666667 0.16666667 0.16666667 0.16666667 0.16666667 0.16666667 0.16666667 0.16666667 0.16666667 0.16666667 0.16666667 0.16666667 0.16666667 0.25 0.25 0.25 0.25 DESIGN-EXPERT Plot Sqrt(Overlap + 2.00) A: Iris Opening B: Angle C: Current Student Residual 0.546705153 0.561589335 -0.49641384 0.230955048 -0.06576049 -0.0763329 -0.4452694 0.578119734 -0.74473098 -0.02354016 -0.13637515 0.071053657 0.789054842 -0.23285521 1.399935528 2.308094749 -0.31160557 -0.09387495 -2.71852686 1.772663718 -1.01027202 -0.79843191 -1.195906 0.091723688 -1.22850436 1.488863216 0.386928155 -0.64728701 Cook's Distance 0.01195546 0.0126153 0.00985707 0.00213361 0.00017298 0.00023307 0.00793059 0.0133689 0.02218497 2.2166E-05 0.00074393 0.00020194 0.0249043 0.00216886 0.07839278 0.21309205 0.00388392 0.0003525 0.29561553 0.12569347 0.04082598 0.02549974 0.05720765 0.00033653 0.10061486 0.14778091 0.00998089 0.02793203 Outlier Run t Order 0.5381966 8 0.5530501 16 -0.488124 15 0.2261409 3 -0.064321 22 -0.074665 13 -0.437371 18 0.5695657 6 -0.737305 12 -0.023023 24 -0.133431 17 0.0694995 7 0.7823729 26 -0.228006 5 1.4315109 27 2.5752153 14 -0.305402 4 -0.091829 21 -3.227371 11 1.8658367 25 -1.010746 9 -0.791934 2 -1.207773 20 0.0897239 19 -1.242974 23 1.5318246 10 0.3796609 1 -0.638905 28 Half Normal plot 99 C 97 95 Half Normal % Probability A AC 90 85 80 70 60 40 20 0 0.00 0.67 1.33 2.00 2.66 |Effect| Graph1: Half Normal Plot of the factor effects 20 DESIGN-EXPERT Plot Sqrt(Overlap + 2.00) Normal plot of residuals 99 95 Normal %probability 90 80 70 50 30 20 10 5 1 -2.72 -1.46 -0.21 1.05 2.31 Studentized Residuals Graph 2: Normal Probability Plot of Residuals DESIGN-EXPERT Plot Sqrt(Overlap + 2.00) Residuals vs. Predicted 3.00 Studentized Residuals 1.50 0.00 -1.50 -3.00 1.52 2.78 4.04 5.30 6.56 Predicted Graph 3: Residuals vs. Predicted 21 DESIGN-EXPERT Plot Sqrt(Overlap + 2.00) Residuals vs. Run 3.00 Studentized Residuals 1.50 0.00 -1.50 -3.00 1 10 19 28 Run Number Graph 4: Residuals vs. Run Number DESIGN-EXPERT Plot Sqrt(Overlap + 2.00) Residuals vs. Current 3.00 Studentized Residuals 1.50 0.00 -1.50 -3.00 0.30 0.37 0.45 0.52 0.60 Current Graph 5: Residuals vs. Current 22 DESIGN-EXPERT Plot Sqrt(Overlap + 2.00) 0.60 Sqrt(Overlap + 2.00) X = A: Iris Opening Y = C: Current 5.72093 Design Points 4.88011 0.52 Actual Factor B: Angle = 67.50 C: Current 4.03928 4 0.45 3.19846 0.37 2.35763 0.30 1.60 1.90 2.20 2.50 2.80 A: Iris Opening Graph 6: Contour Plot with Iris Opening DESIGN-EXPERT Plot Sqrt(Overlap + 2.00) X = A: Iris Opening Y = C: Current Actual Factor 6.56175 B: Angle = 67.50 5.30052 4.03928 Sqrt(Overlap 2.77804 + 2.00) 1.51681 0.60 2.80 0.52 C: Current 2.50 0.45 2.20 0.37 1.90 0.30 A: Iris Opening 1.60 Graph 7: 3D Response Surface Plot 23