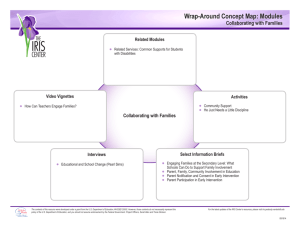

IRIS Presentation Nov. 2013 - International Projects Office

advertisement

‘SME Success story’ 3rd Pan-European SME Event Vision 2020 Barcelona, 4th April 2014 How we started Process engineerin g company • • • 2007 Own capital 150 K Loan €100K 20 m2 office in Barcelona Vision to create an R&D and advanced engineering company to ‘bridge innovation gap’ Our positioning Strategically positioned between Universities and Industry: specialising in scaling up technology & processes from lab to production line How we grew 48 staff 32 staff Commercial team 25 staff 20 staff Investment electronics lab 14 staff Move to ‘Mediterranean Technology Park’ 2 staff 2008 20m2 2007 3 R4SME 2 R4SME projects 1 SMEAG Agreement to access Uni labs Investment in own laboratories & workshops 2010 2009 3 R4SMEs 1 SMEAgs 3 R4SMEs 1 SMEAGs 2 private contracts Internationalisation (Ireland) 2011 4 R4SMEs 1 SME-AGs 1 MANUNET 1 NMP 3 private contracts 44 staff Operations & procedures 2012 5 R4SME 1 SME-AG 2 DEMO 1 MANUNET 1 KBBE 5 private contracts ISO & UNE Certification 2013 5 SME projects 1 SME-AG 1 DEMO 1 MANUNET 1 KBBE 7 private contracts New product development ‘To-market orientation’ A successful campaign in FP7 25 %- PhD qualified Continuous investment for Growth 40 projects 2 KBBE 1 NMP 3 MANUNET 31 Research SMEs/Ags 3 DEMO Actions 34 led by IRIS Knowledge Revenue Talent Experience Networks • • • > €40 M in total > €14.5 M for IRIS €1.1 M from projects led by third parties Engineering team • Optical 48 staff test rigs •• Building Mechatronic 2 sites (BCN, Dublin) • Scaling up prototypes Electronics • Integration Engineering Programmers&workshops Modellers • demonstration Labs (optics, telecos, in industry •• Laboratory Software analytical, wet chemistry) validation • Telecommunications Pilot facilities (Plasma, • Industrialisation • Mechanical PEF, Ultrasound, • Project Management Bioreactor, Coating line, • Knowledge Management Scientific team HIS & NIR Management integrated into a •• Innovation Chemists • conveyor Biologists line •• Innovation Hub Microbiologists (accelerator environment & • Biochemists • Physicists sprint room) Examples of scaled up results in FP7 IRIS evolution Are there any keys to our success? 1. Hard work 2. Continuous improvement 3. Talent 4. Invest, invest, invest 5. Long-term vision 1. What did we do well at proposal level? 2. 3. 4. 5. Ideas that make market sense Make our ideas as ‘physical’ as possible Strong and relevant partners (and win-win) Branding Impact, impact, impact 1. What did we do well at project level? 2. 3. 4. 5. Good project managers and procedures Operations (from automotive sector) Create a ‘project team’ Understand who the client is Risk management and quick action Lessons we learned the hard way? 1. 2. 3. TRLs (make sure technology is ready to come out of lab) Staff (right person right job) Operational planning (no fire fighting!) The future is bright We see H2020 as a great opportunity A strategy for GROWTH and JOBs • helping to bridge the gap between research and the market • helping innovative enterprise to develop their technological breakthroughs into viable products with real commercial potential • promoting activities where businesses set the agenda • prototypes, pilot implementations, demos, etc. Innovation Union V2020: Building our networks and forming part of a community IRIS has recently joined as an SME A platform for meeting RTO and SME collaborators member A community to share ideas, knowledge, advice and experience A source of partners and quality proposal concepts Visibility Building opportunities together What’s on the Horizon for IRIS thanks to our success in FP7? • • • • • • • Product launch in 2014 Branch facility in Hong Kong 3 patent applications 1 joint company (WHEYLAYER Ltd.) Joint development with global multinational for biomaterials development Exclusive integrator for 2 optical hardware companies B2B contracts with leading food & pharmaceutical companies