MEC316 Lab#5

advertisement

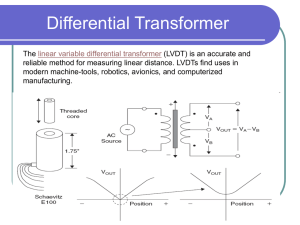

MEC316 Lab#5 Straightness Measurement of Linear Motion & LVDT Calibration Group #9: Kanchan Bhattacharyya – Writer; Synthesizing Paper Matthew Stevens – Graphs & Error Analysis Ting Zhang – Materials & Methods Xie Zheng – Abstract; Introduction; Experimental Procedure Abstract The general goal of this metrology experiment is first to learn how to use a digital indicator, a straightedge and the principle of straightedge reversal to measure the straightness of a linear slide as well as the shape of the straightedge. Since there is no exact straight object, we have to use the method to cancel out the error. In this experiment, for measuring the straightness of machine tool slideways, we are using the dial indicator and straightedge method which is applied with the principle of straightedge reversal. For the straightedge reversal, it consists of two measurement setups. The straightedge is first supported on its side with the gauging surface in a vertical plane, in what is arbitrarily called the “normal” orientation. The equation we are using in this experiments are: N(x) = M(x) - S(x) where M(x) is the error of the machine and S(x) is the shape of the straightedge. When we flip over the straightedge, we have another new set of displacement: R(x) = -M(x) - S(x) where R(x) is the displacement for the reversal setup. By combing these two equations, we can get two new equations M(x) = [N(x) R(x)]/2 and S(x) = -[N(x) + R(x)]/2. From these two equations, once we obtain the data from measuring, we can easily find the straightness of a linear slide as well as the shape of the straightedge. In this method, the reason why we flip over the straightedge is making another set of the measurement which is “reverse” to the first step. By subtracting them with each other, we can cancel out the differences between them and the new data will come out which is twice of the distance for the shape of the straightedge and also the straightness of the linear slideways. For this experiment, we need to do three times of the measurements which all have two steps to measure the both side. In total, we need to have 6 sets of the data with 26 positions. It is also a calibration method for measuring the machine tools. The other general goal of this experiment is the calibration of the LVDT which stands for Linear Variable Differential Transformer. The LVDT is frequently used to measure displacements and produces an analog signal output. It can be used with computer aided data acquisition systems. For this part of experiment, we need to measure the micrometer position and LVDT output voltages for three times separately which is just like the first part of the experiment. Due to the principle of the operation of the LVDT, there is a relation between the output voltage and the micrometer position. By measuring these two measurements, we can finally look into the plot (with doing the linear regression) to see if the relation is linear or not. Introduction Calibration of machine tools is an essential operation in the machine tool industry. For every time that we need to some measurement of the certain object, we always use the machine tool as the standardization. Since it would be perfect for machinists to get a more standard tool which is not possible, finding out the error of the tool itself becomes more important as we can take the error of the tool into the calculation to make sure we get the results as accurate as possible. So, it is routinely performed to keep machines in their peak performance and therefore to produce quality products. Some important purpose of calibration can be summarized as follow: 1) error mapping of CNC machines for error compensation, 2) acceptance testing of newly acquired machine tools, 3) periodic calibration for optimized performance of machine tools, 4) troubleshooting, and 5) demonstration of quality to potential customers. For this experiment, we are measuring the straightness of a linear slide by using the digital indicator which could display the reading of the distance from the object. Be more specific, the reading on the digital indicator is somehow the differences between the distances from the digital indicator to the straightedge since the indicator can be reset to make the reading which indicates the distance to zero. Then, when we move the digital indicator along the slide way, the reading starts to change which means the distance is changing at the same time and the we can get the measurement of the distance by recording the reading from the digital indicator. That is the principle of the operation of using the straightedge with a digital indicator. Nevertheless, there is nothing exactly straight. For this experiment, we are using a method which is called straightness measurement of machine tool slideways which is one of the major operations of machine tool calibration. Conventionally, straightness measurement has been done by using such instruments as dial indicators and straightedge, laser interferometer, etc. in this kind of experiments, we use the former set since that method is a simple and elegant method, especially when the principle of straightedge reversal is applied. As for the calibration of an LVDT (Linear Variable Differential Transformer), the three coils are placed in a linear arrangement with a magnetic core which may move freely inside the coils. An alternating input voltage is impressed in the center coil, and the output voltage form the two end coils depends on the magnetic coupling between the core and the coils. The coupling is dependent on the position of the core. Thus, the output voltage of the device is an indication of displacement of the core. Since then, we can look into the relation between output voltage and the micrometer positions. Theory Part I (Straightness Measurement of Linear motion) Figure 5-1 shows all six geometric error components of a linear slide. Among these error components, the horizontal straightness is to be measured in this experiment. One way to measure the straightness of a linear slide is to use a dial indicator and a mechanical straightedge which serves as a reference. Since no real straightedge is perfectly straight, errors in the shape of the reference artifact mixed with the slide errors one is trying to measure. This problem is readily solved by a simple and elegant technique known as straightedge reversal. Fig 5.2 illustrates the principle. Straightedge reversal consists of two measurement setups. The straightedge is first supported on its side with the gauging surface in a vertical plane, in what is arbitrary called the “normal ” orientation. A series of data is taken at a chosen number of carriage position, which can be represented as N(x)=M(x)-S(x) where M(x) is the error of the machine and S(x) is the shape of the straightedge. In the second setuo, the straightedge is rotated 180 degree about its long axis, and the dial indicator is also rotated so as to sample the reoriented surface. This is called the “reverse” orientation. With this setup, a new set of displacements R(x)=-M(x)-S(x) is obtained. From the results of these measurements, both the slide horizontal straightness and the shape of the straightedge can be determined as M(x)=[N(x)-R(x)]/2 and S(x) =-[N(x)+R(x)]/2 respectively. Figure 5.3 shows a typical measured result of straightness of motion. It can be considered as consisting of a straightness of motion error es (the miminum distance of two parallel lines enclosing the curve) and an error of direction ed(the slope of these lines). ed could be caused by misalignment of the straightedge and the motion direction. It cannot be accurately determined from this experiment. Therefore it is eliminited from consideration in this experiment through linear regression analysis. es is the error to be measured.(We assume that theta is small) Instruments (Straightness Measurement of Linear Motion) 1. A digital indicator (Mitsutoyo Digimatic Indicator model 543-142) with a measuring range of 0-.5’’/0-12.7 mm, a resolution of .0005’’/0.001 mm, and an accuracy of .00015’’ 2. A rectangular straightedge with hardened steel 3. A linear slide (NS K Monocanier model MSM0803OH-10) with a leadscrew of 10 mm pitch and a differential manual drive (Klinger Model UE2.30.N) 4. A full 360 degree rotary stage (Newport Model RSP-1) Procedure (Straightness Measurement of Linear Motion) 1.We check the measuring tip of the digital indicator is roughly aligned with the slide axis, the digital indicator is on the right hand side, and the reading of the counter on the slide drive is 9990. This is the first stage of the setup. 2. Turn on the digital indicator and lightly clamp the straightedge in the fixture. 3. Rotate the rotary stage to make sure the measuring tip of the digital indicator forms a right angle with the gauging surface of the straightedge and the arrows on the rotary stage are aligned. For making sure the measuring tip of the digital indicator is vertically against the gauging surface, we rotate the rotary stage and observing the reading displayed on it. When the reading comes to either largest or smallest, that means the measuring tip of the digital indicator is vertically against the gauging surface. 4. Press the “reset” button on the digital indicator twice to get the zero reading on it. 5. We start to take the positions of the indicator by turning the drive by every half revolution which would distribute 5mm on the distance along the slide way. In this experiment, our instrument already had the marks on the drive which are opposite to each other. So we make one of them as the starting point and then the other one would be the mark for next measurement. By taking 26 measurements, we record the readings in the computer which are displayed on the screen and put them as N(x). 6. Unlock the rotary screw. Rotate the rotary stage to align the digital indicator roughly with the axis of the slide. Move the slide back until the counter number is 9990 again. 7. Rotate the straightedge for 180 degrees about its long axis and lightly clamp it in the fixtures on the other side of the slide so as to face the same gauging surface of the straightedge to the digital indicator. 8. Repeat steps 3,4,5 to take the set of 26 measurements for R(x). 9. For doing this measurement three times, we repeat steps 3 – 8 for another twice. 10. Turn off the digital indicator and save all the data. Theory Part II: (Calibration of a Linear Variable Differential Transformer) The LVDT is usually used to measure displacements and gives an analog signal output. It can also be used with computer aided acquisition systems. In schematic diagram of the differentail transformer, we can see three coils are placed in a linear arrangement as shown with a magnetic core which may move freely inside the coils. The voltage output actually indicts the postion change of the transformwe. The insight construction of the device is shown in Fig 5-10. An alternating input voltage is impressed in the center coil, and the output voltage from the two end coils depends on the magnetic couple between the core and the coils. This coupling , in turn , is dependent on the position of the core. Thus the output voltage of the device is an indication of displacement of the core. The excitation of such device is normally an sinusoidal voltage of 3V to 15V rms ampplitude and frequency of 60Hz to 20,000Hz, The two identical secondary coils hace induced in them sinusoidal voltage of the same frequency as the excitation; however, the amplitude varies with the position of the iron core. When the secondaries are connected in the series opposition, a null position exists at which the net output e0 is essentially zero. Motion of the core from null then causes a larger mutual inductance(coupling) for one coil and a smaller mutual inductance for the other, and the amplitude of e0 becomes a nearly linear function of core position for a considerable range either side of null. The voltage e0 undergoes a 180 degree phase shift in going considerable range either side of null. These instruments record the actual waveform of the output as an amplitude-modulated sine wave, which is usually underdesirable. What is desired is an output-voltage record that looks like the mechanical motion being measured. To achieve the desired results, demodulation and filtering must be performed; if it is necessary to detect unambiguously the motions on the both sides of null, the demodulation must be phasesensitive. Fig 5.11 shows the circuit arrangement for phase-sensitice demodulation using semiconductor diodes. Ideally, these pass current only in one direction ; thus when f is positive and e is negative, the current path is efgcdh, while when f is negative and e positive, the path is ehedgfe. The current through R is therefore always from c to d. A similarly situtaion exists in the lower diode bridge. It is then necessary to connect e0 of Fig 5.11 to input of a low-pass filter which will passs the frequencies present in xi but reject all those (higher) frequencies produced by the modulation process. The design of such a filter is eased by making the LVDT excitation frequency much higher than the xi frequencies. Calibration The output from an LVDT is an analog signal proportional to the displacement. The relationship between the displacement and the output voltage must be found, then the displacement can be determined. Instruments Part II – LVDT Calibration 1.An LVDT Calibration unit with micrometer 2.Radio Shack Digital Multimeter Procedures (Calibration of a Linear Variable Differential Transformer) 1. Insert the LVDT into the calibration unit. 2. Set the micrometer to zero 3. Push the LVDT all the way to the exterme position against the flat tip of the micrometer 4. screw tight LVDT 5. Connect the output of the LVDT system to a Multi-meter and set to “DC voltage”. 6. Record the inital voltage when the micrmeter is zero 7. Set the increment displacement to 0.01 in 8. The read and record the voltage showed on the multimeter 8. Continue 30 trials until the displacement reached 0.3 in 7.Plot out the displacement-voltage output curve of the LDVT. CONCLUSION In general, this experiment was conducted to utilize the straightedge reversal method in calculating the error in straightness of a test piece with respect to a standard straightedge. Going in the normal and reverse direction and doing straightness and straightedge shape calculations are there to ensure that the actual error in the straightedge itself is not included when determining the straightness of the test piece, which is quite remarkable. As per the low deviation from trial to trial, it’s easy to see that there is a high rate of reproducibility in this method. However, it would be more accurate if a digital readout for the horizontal displacement is provided to match the accuracy in the digital readouts of the track error from the straightedge. It results in that extremely accurate data values from the digital readout of the track error being correlated to relatively poor hand-eye measurements of track displacement via the knob. This covers the 0.1 deviation we see on average from trial to trial on the straightness error. The angle of tilt between the straightedge and the track can be easily illustrated using the straightedge reversal method as we discussed in the context of Trial 3, and the difference in the straightedge shape to carriage position in the normal and reverse directions indicate which way the track is slanted towards which is not considered in the straightness error calculation derived in the linear regression. ERROR ANALYSIS Sources for error during the experiment include those attributed to improper calibration, flaws in experimental setup, and errors occurring during measurement. When measuring the straightness of the straightedge our accuracy was dependent on both the accuracy in which the experimental setup was assembled as well as our own measuring accuracy. Similarly, when calibrating the LVDT we relied on the accuracy of the LVDT/DAQ Interface and our own measuring accuracy in addition to that of the LVDT itself. When measuring the straightness of the straightedge we consider first the errors arising from flaws in the experimental setup and calibration. When measuring the straightness of both the normal and reverse orientations of the beam we measure under the presumption that each respective side is resting in direct contact with the supports used to fasten the straightedge. We can similarly consider that we are assuming that the supports themselves, possess perfectly-straight faces which come into contact with the straightedge. Any variance in the straightness of the supports holding the straightedge will result in a variance that may not be characteristic of the material. We can also consider the errors that may be consequence of an improperly calibrated or malfunctioning micrometer, as well as flaws that may exist in the knob-assembly used to translate the micrometer across the length of the straightedge. Errors in the micrometer would give inaccurate measurements when measuring straightness, and we can consider these errors would exist for every measurement. Similarly, any hindrance in the mobility of the knob mechanism translating the micrometer across the straightedge could give straightness results associated with an inaccurate position along the straightedge. In addition to considering errors arising from improper calibration and experimental setup we can consider those existing in our own measuring ability. While we relied on the micrometer for position readings along the straightedge, these readings were made by translating the micrometer across the surface of the straightedge via a manually turned knob. We attempted to make our measurement increments as consistent as possible, under the premise that if we turned the knob a half revolution for each measurement we would achieve near consistent displacements. In reality, we arbitrarily chose two points on opposing ends of the circumference of the knob as our beginning and ending points for each displacement and assumed that they were exactly 180° apart from one another. Similarly, we can also consider the reality that we were not pin-point precise with each measured half-revolution. While we were careful in making sure that we chose consistent starting and ending points for each displacement, there is the possibility that a measurement was made prematurely or further along the surface than intended. These errors would give an inaccurate profile for the horizontal straightness of the surface, and we might conclude that variant degrees of straightness exist for specific points along the surface of the straightedge. Similar sources for error could have rendered inaccurate results in the LVDT Calibration Trials. First we can consider inaccuracies that manifest from improper LVDT calibration. Improper LVDT calibration would result in variant output voltages and subsequently give an inaccurate profile for the LVDT output voltage versus displacement versus curve. Similarly, we can consider variances attributed to improper micrometer calibration. Improper calibration of the micrometer would render LVDT output voltages for incorrect positions, which would also render an inaccurate output voltage vs. displacement curve. In addition to the errors resulting from improper calibration, we can consider those associated with improper experimental setup and component interfaces. Specifically, we can consider the interface between the LVDT and the micrometer tip and how any variance in the contact between the two will affect the output voltage in addition to improper multi-meter calibration. To obtain the true output for a given micrometer reading, we require that the LVDT be securely fastened to the calibration unit via a set screw. Securing the LVDT ensured a constant LVDT/Micrometer interface, therefore insuring that any displacement made by the micrometer would result in a corresponding variant LVDT output voltage. Without full contact between the LVDT and the micrometer subsequent displacements would not render the expected output voltages and in the extreme case would result in identical outputs for different displacements. Finally we can consider errors due to inaccuracy in our measurements, specifically those associated with micrometer displacement. While we measured what we considered to be even and accurate displacement intervals, we account for variances in our measurements. Inaccurate displacement intervals would render LVDT output voltages variant of the ‘true’ voltages, as we would associate a given voltage with an inaccurate micrometer position. Linear Regression Analysis of the Horizontal Straightness of the Straightedge rendered linear relations for the three trials of y = 0.119 + 0.346x, y = 0.149 + 0.376x, and 0.107 + 0.337x, respectively. When considering the uncertainties associated with the coefficients a and b, we found relatively small values for the uncertainty in a of 0.007mm, 0.006mm, and 0.007mm and slightly larger uncertainties in b of 0.346 mm, 0.335 mm, and 0.489mm. Similarly, linear regression of the LVDT Output Voltage data rendered a linear curve fit of the form y = -4.897 + 21.018x volts, with uncertainties of 0.180 volts in A and 1.031 volts in B. These uncertainties are well within the expected acceptable errors.