An improved Radial 8 fold dipole

advertisement

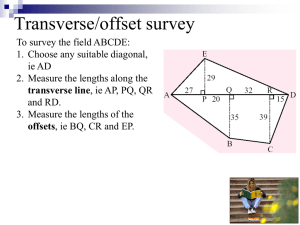

An improved Radial 8 fold dipole June 28, 2006 Paul Brindza An improved radial dipole is presented that features right circular cylinders for the poles and wedge shapes for the yoke inside the coils. The eight coils are cosine(theta) type coils but in this specific geometry they are simply racetrack coils wound on an inside cylinder. TOSCA’s cosine theta generator is used for convenience. Fig 1 shows the geometry of the magnet as modeled in TOSCA with the reflections. A conventional coil is assumed with water cooled hollow copper conductor running at an average of 500 Amps/cm^2. The coil cross section is 0.5 M radial and by 0.16 M along phi. The use of cylindrical poles helps flatten the field as one goes around in Phi as shown in Fig 2 and the radial field dependence is reduced compared to the previous work on this subject and is shown in Fig 3. The magnet‘s yoke is 1 meter long in Z. The yoke inside radius is 1.5 M and the yoke outside radius is 2.5 meters and the yoke cylinders are 0.25 M thick. The gap is ~ 0.5 M radially and ~ 0.5 meter wide in Phi and the inside radius is 1.75 M and the outside radius is 2.25 M. I should note that this magnet is basically an octupole with shorted poles. This means the like all multipole magnets, this magnet suffers from pole root saturation. Indeed the maximum field is limited for the radial dipole by the fact that the iron core inside the coil is at 2.01 Tesla see fig 4. An excellent large acceptance focusing spectrometer could be made by using Q1 and Q2 from HRS mounted upstream of the radial dipole amd near the target. This would work even for the proposed use of the radial dipole for a parity experiment where the Quads would be coaxial with the electron beam as would the radial dipole. Tosca model of 8 fold radial dipole Detail of one sector fo the radial dipole Phi dependence of the Radial field component Radial dependence of the Br field in the radial dipole Yoke saturation, note that the core or “hub” of the coil is at 2.01 Tesla for a central field of ~ 1 Tesla. The “pole” iron rings are also somewhat saturated and this can be corrected by thickening. The coil hub iron problem cannot be fixed except by operating at lower current or a smaller gap width.