Abdomen Foam

advertisement

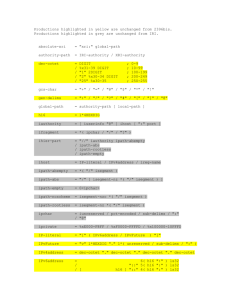

H16 Hybrid III Abdomen Foam 1. MATERIAL MORPHOLOGY Name Code Structure Color Average Density : : : : : Hybrid III Abdomen Foam H16 Open cell foam White 0.1387 (g/cm3) H16 is an homogeneous and isotropic foam (Figures H16-4,5,7) 2. EXPERIMENTAL DATA Compression : Fig. H16-1, Fig. H17-2, ISO delivered data Tension : Fig. H17-6, Fig. H17-8 , ISO delivered data 3. SUMMARY of MECHANICAL BEHAVIOR 3.1. COMPRESSION ( Quasi-Static and Dynamic) 3.1.1. Stain Rate dependence The mechanical properties of H16 in compression, exhibit small strain rate dependence. Experimental results of quasi-Static and Drop Weight Method are given in Figure H16-1 and Figure H16-2 respectively. 3.1.2. Sensitivity to Loading History The mechanical properties of H16 are stable independent from the loading history (Figure H163). The material H16 is homogeneous (Figure H16-4) and isotropic (Figure H16-5). 3.2. TENSION ( Quasi-Static and Dynamic) 3.2.1. Stain Rate dependence The behavior of H16 in tension is not stain rate dependent (Figure H16-6). 3.2.2. Sensitivity to Loading History The material H16 is homogeneous and its mechanical properties are independent from the loading history (Figure H16-7) H 16 Abdom en Foam Q u a s i - s ta tic C o m p re s s io n T e s ts T h e s tra in ra te e ffe c t 1 .4 0 .1 0 1 .2 0 .0 8 S tress MP a Stress MPa 1 .0 0 .0 6 0 .0 4 0 .8 0 .0 2 0 .6 0 .0 0 0 0 .3 0 .6 0 .9 s tr a in 0 .4 0 .2 3 1 5 0 .0 4 6 3 0 .0 2 3 1 0 .2 0 .0 0 4 6 0 .0 0 2 3 0 .0 0 0 .2 0 .4 0 .6 0 .8 1 s tra in Figure H16-1 Cyclic compression experiments at five different strain rates indicate that there is a small strain rate effect of the behavior of H16 in compression H16 Abdomen Foam Comparison between Quasi-Static and Dynamic Compression The Strain Rate Effect 0.2 0.18 C 61.6s-1 C 36.5s-1 C 50.6s-1 0.2315 0.0463 0.0231 0.0046 0.0023 0.16 stress (MPa) 0.14 0.12 0.1 0.08 0.06 0.04 0.02 0 0 0.2 0.4 0.6 0.8 1 strain Figure H16-2 Comparison between Quasi-Static and Dynamic Compression H16 Abdomen Foam Quasi-Static Cyclic Compression Setting of the Material Strain Rate 0.033 s-1 0.60 0.40 Stress (MPa) 1st cycle 5th cycle 0.20 0.00 0.0 0.2 0.4 0.6 0.8 1.0 strain Figure H16-3 Cyclic compression experiments up to 0.9 stain on the same sample demonstrate that the material is not affected by the loading history. H 16 Ab d o m en F o am Q u a s i-S ta tic C y c lic C o m p re s s io n H o m o g e n e ity a n d D ire c tio n a lity S t r a in Ra t e 0 .0 3 s -1 0 .5 0 0 .4 0 s p e c im e n 2 Stress (MPa) s p e c im e n 1 0 .3 0 0 .2 0 0 .1 0 0 .0 0 0 .0 0 .2 0 .4 0 .6 0 .8 1 .0 s tra in Figure H16-4 Cyclic compression experiments up to 0.9 stain on two different samples cut from different sites of the delivered sample demonstrate that the material is homogeneous with the same mechanical properties in compression. H 16 Abdom en Foam Q u a s i-S ta tic C y c lic C o m p re s s io n E ffe c t o f D ire c tio n o f L o a d in g S tr a i n R a te 0 . 0 2 s - 1 0.800 0.700 x -d ire c tio n y -d ire c tio n z -d ire c tio n 0.600 S tress (MP a) 0.500 0.400 z 0.300 y 0.200 x 0.100 0.000 0.0 0.2 0.4 0.6 0.8 1.0 s tra in Figure H16-5 Cyclic compression experiments to the same cubic sample demonstrate that the material is isotropic H16 Abdomen Foam Quasi-Static Cyclic Tensions Strain Rate Effect 0.030 0.0016 0.0033 0.025 0.0055 0.0163 Stress (MPa) 0.020 0.0276 0.0327 0.015 0.0551 0.010 0.005 0.000 0.00 0.05 0.10 0.15 0.20 0.25 strain Figure H16-6 Cyclic tension experiment indicate that there is a very small strain rate effect of the behavior of H16 in tension H16 Abdomen Foam Quasi-Static Cyclic Tension Effect of loading direction and history 0.030 y-direction (2nd run) 0.025 z-direction (1nd run) z-direction (2nd run) Stress (MPa) 0.020 0.015 0.010 0.005 0.000 0.00 0.05 0.10 0.15 0.20 0.25 strain Figure H16-5 Cyclic tension experiments on two different specimens cut from different sites of the delivered sample demonstrate that the material is homogeneous isotropic and unaffected by the loading history.